Feb . 07, 2025 02:12

Back to list

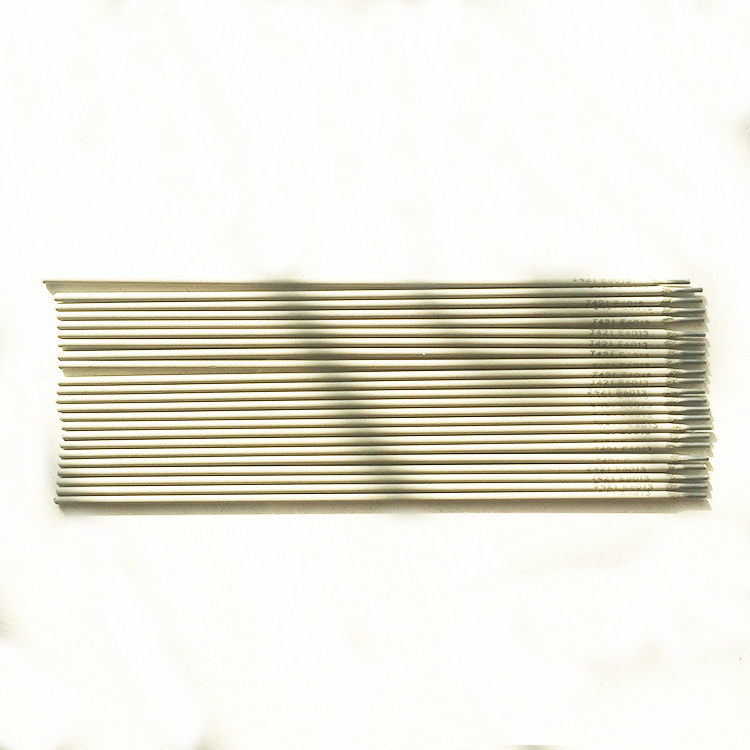

2 gauge welding wire

When it comes to welding, the choice of equipment is paramount; and among the most critical components is the wire gauge, specifically the 2-gauge welding wire. For welding enthusiasts and professionals alike, understanding the nuances of choosing the right wire can significantly influence the quality and efficiency of their work.

Authoritativeness in Application The versatility of the 2-gauge welding wire is what makes it a staple in various industrial settings. Its use is extensively documented across several sectors, including shipbuilding, construction, and automotive industries. Authoritative welding guides often recommend 2-gauge wire whenever high strength and deep weld penetration are required. For instance, in automotive repair, where vehicles' frames require reinforcement or repair, using a 2-gauge wire ensures that the welds can withstand significant stresses and strains over time. Similarly, in shipbuilding, where safety and integrity are paramount, 2-gauge wires contribute to the seamless joining of massive steel sections. Trustworthiness Through Proven Performance Reliability in welding comes from knowing that the materials used will perform as expected every time. In my career, the track record of 2-gauge welding wires has proved time and time again their ability to deliver consistent and trustworthy results. The manufacturing processes behind quality 2-gauge wires typically involve stringent quality control checks that reinforce their suitability for demanding applications. Experienced welders place their trust in these wires' performance because they have been tested and proven across countless projects. The confidence that a flawless, strong weld is achievable with 2-gauge wires is not just theory; it's backed by years of empirical evidence and real-world applicability. In conclusion, for serious welding tasks that demand precision, power, and performance, the 2-gauge welding wire stands out as an indispensable asset. Emphasizing the experiential feedback from professionals, expert selection advice, authoritative application, and its proven reputation for trustworthiness, it remains a top choice for those in the welding industry aiming for excellence. Selecting the right tools, including the 2-gauge welding wire, is not just about the present task but ensuring long-term success and sustainability in all welding projects.

Authoritativeness in Application The versatility of the 2-gauge welding wire is what makes it a staple in various industrial settings. Its use is extensively documented across several sectors, including shipbuilding, construction, and automotive industries. Authoritative welding guides often recommend 2-gauge wire whenever high strength and deep weld penetration are required. For instance, in automotive repair, where vehicles' frames require reinforcement or repair, using a 2-gauge wire ensures that the welds can withstand significant stresses and strains over time. Similarly, in shipbuilding, where safety and integrity are paramount, 2-gauge wires contribute to the seamless joining of massive steel sections. Trustworthiness Through Proven Performance Reliability in welding comes from knowing that the materials used will perform as expected every time. In my career, the track record of 2-gauge welding wires has proved time and time again their ability to deliver consistent and trustworthy results. The manufacturing processes behind quality 2-gauge wires typically involve stringent quality control checks that reinforce their suitability for demanding applications. Experienced welders place their trust in these wires' performance because they have been tested and proven across countless projects. The confidence that a flawless, strong weld is achievable with 2-gauge wires is not just theory; it's backed by years of empirical evidence and real-world applicability. In conclusion, for serious welding tasks that demand precision, power, and performance, the 2-gauge welding wire stands out as an indispensable asset. Emphasizing the experiential feedback from professionals, expert selection advice, authoritative application, and its proven reputation for trustworthiness, it remains a top choice for those in the welding industry aiming for excellence. Selecting the right tools, including the 2-gauge welding wire, is not just about the present task but ensuring long-term success and sustainability in all welding projects.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025