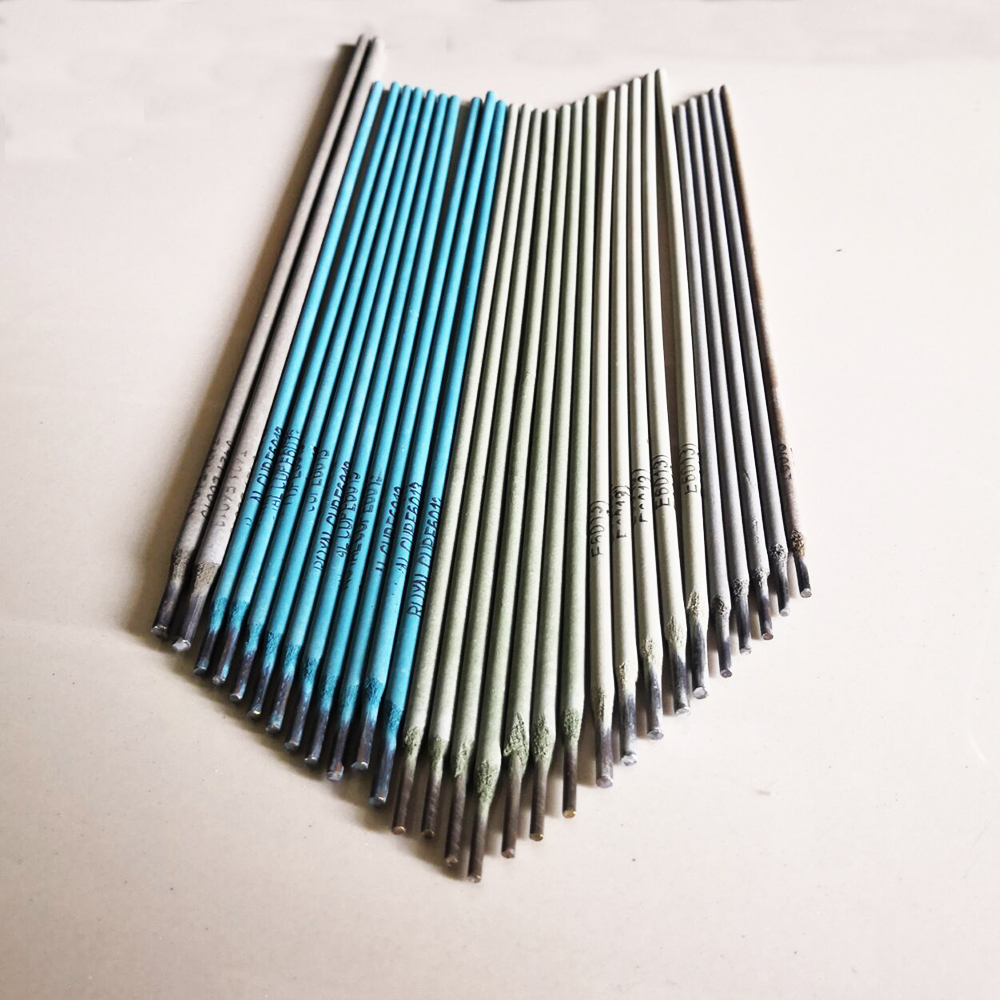

308 welding electrode suppliers

The Importance of Choosing the Right 308 Welding Electrode Suppliers

When it comes to welding, selecting the appropriate materials is crucial for ensuring high-quality results and the longevity of welded structures. Among these materials, welding electrodes stand out as a fundamental component. Specifically, 308 welding electrodes are widely used for stainless steel welding due to their excellent corrosion resistance and high ductility. However, the effectiveness of these electrodes greatly depends on the suppliers from whom they are sourced.

Understanding 308 Welding Electrodes

308 welding electrodes are primarily used for welding stainless steel types that contain chromium and nickel. They are designed to create a stable arc and minimize spatter, which enhances the overall quality of the weld. This type of electrode is especially favored in applications requiring high strength and durability in corrosive environments, making them a popular choice in industries such as food processing, pharmaceuticals, and construction.

The Role of Suppliers

The quality of welding electrodes can vary significantly between suppliers. Therefore, choosing reputable 308 welding electrode suppliers is essential for several reasons. First and foremost, a reliable supplier ensures that the electrodes are produced under strict quality control processes. This not only guarantees the consistency of the product but also ensures that it meets necessary industry specifications and standards.

Additionally, established suppliers often offer a range of products tailored to different welding needs. They may provide electrodes of various diameters and specifications suitable for different welding techniques. This diversity allows welders to select the right product for their specific applications, ensuring both efficiency and effectiveness in their work.

Factors to Consider When Choosing Suppliers

308 welding electrode suppliers

1. Quality Assurance Check if the supplier adheres to international standards such as ISO or AWS. A reputable supplier will often provide certification for their products, which serves as a testament to their quality.

2. Range of Products Look for suppliers who offer a broad selection of 308 electrodes, including different sizes and coatings. This can be crucial for specialized welding tasks.

3. Customer Support Good suppliers provide excellent customer service, including technical support. They should be willing to answer questions and offer advice on the best products for specific projects.

4. Reputation and Reviews Research the supplier's reputation in the market. Online reviews and testimonials from previous customers can provide insights into their reliability and the quality of their products.

5. Pricing While it may be tempting to choose the cheapest option, consider the long-term value. Sometimes, investing in higher-quality electrodes can yield better results and save costs associated with rework and repairs.

Conclusion

In conclusion, the selection of a reliable 308 welding electrode supplier is a critical aspect of welding operations. High-quality electrodes contribute to superior welds that can withstand demanding conditions. By considering factors such as quality assurance, product range, customer support, reputation, and pricing, welders can ensure they partner with suppliers that will meet their needs effectively. Ultimately, choosing the right supplier can make a significant difference in the success of welding projects and the overall integrity of the final product.

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025