china 60 10 welding rod manufacturers

The Future of Welding Rod Manufacturing in China A 2060 Vision

As we traverse the path towards the year 2060, the landscape of manufacturing in China, particularly in the welding rod sector, is poised for transformation. Welding rods are essential components in various industrial applications, including construction, automotive, and shipbuilding. Given the rapid advancements in technology, environmental policies, and global economic trends, it is pertinent to envision what the welding rod manufacturing industry in China might look like 40 years from now.

Technological Advancements

By 2060, we expect that the welding rod manufacturing processes in China will be revolutionized through the integration of advanced technologies such as artificial intelligence (AI), machine learning, and automation. These technologies will streamline production techniques, enhance quality control, and reduce operational costs. Smart factories equipped with IoT (Internet of Things) devices will enable real-time monitoring of manufacturing processes, leading to quicker adjustments and minimizing wastage.

Furthermore, the development of new materials will likely play a pivotal role in the welding rod industry. Research into advanced alloys and composite materials may yield welding rods that provide superior performance, including higher tensile strength, corrosion resistance, and improved melting points. These advancements will not only improve the quality of welds but also broaden the application scope for welding rods.

Environmental Sustainability

With climate change being one of the most pressing issues of our time, China's approach to welding rod manufacturing will undoubtedly embrace sustainability by 2060. Governments and corporations alike will prioritize eco-friendly practices. Manufacturing facilities will be expected to adopt cleaner production techniques, utilize renewable energy sources, and implement rigorous recycling programs for waste materials.

As part of the global commitment to reduce carbon emissions, the welding rod industry will likely shift towards green technology. This could involve the development of biodegradable welding rods or those produced from recycled materials. Manufacturers will be competing not just based on price and quality but also on their environmental footprint, making sustainability a key competitive differentiator in the market.

china 60 10 welding rod manufacturers

Global Market Dynamics

The global economic landscape will continue to evolve by 2060, and China’s welding rod manufacturers will need to adapt to these changes. As emerging markets expand and other countries ramp up their manufacturing capabilities, competition will intensify. Chinese manufacturers will be compelled to innovate and diversify their product offerings to maintain their position in the global marketplace.

Additionally, geopolitical factors may influence trade relations, affecting supply chains and pricing. To mitigate risks, manufacturers might explore vertical integration, securing their raw material sources, and enhancing their export capabilities. Collaborations and partnerships with foreign companies could also become a common strategy to foster innovation and market access.

Skilled Workforce and Education

A crucial element for the future of the welding rod industry will be the availability of a skilled workforce. As technology becomes more complex, the demand for engineers, technicians, and skilled labor will soar. China’s educational institutions will need to focus on technical training and vocational education to prepare the workforce for the evolving landscape.

By 2060, we may see the establishment of specialized programs and institutions dedicated exclusively to welding technology and materials science. Additionally, continuing education and retraining programs for current workers will be essential to keep pace with technological advancements and industry standards.

Conclusion

In conclusion, the welding rod manufacturing industry in China is on the brink of a substantial evolution by the year 2060. With the integration of advanced technologies, a commitment to sustainability, adaptations to global market dynamics, and a focus on developing a skilled workforce, the industry has the potential to thrive in an increasingly competitive and environmentally conscious world. As we look forward, it is crucial for stakeholders in the welding rod sector to remain innovative, adaptable, and proactive in facing the challenges and opportunities that lie ahead.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

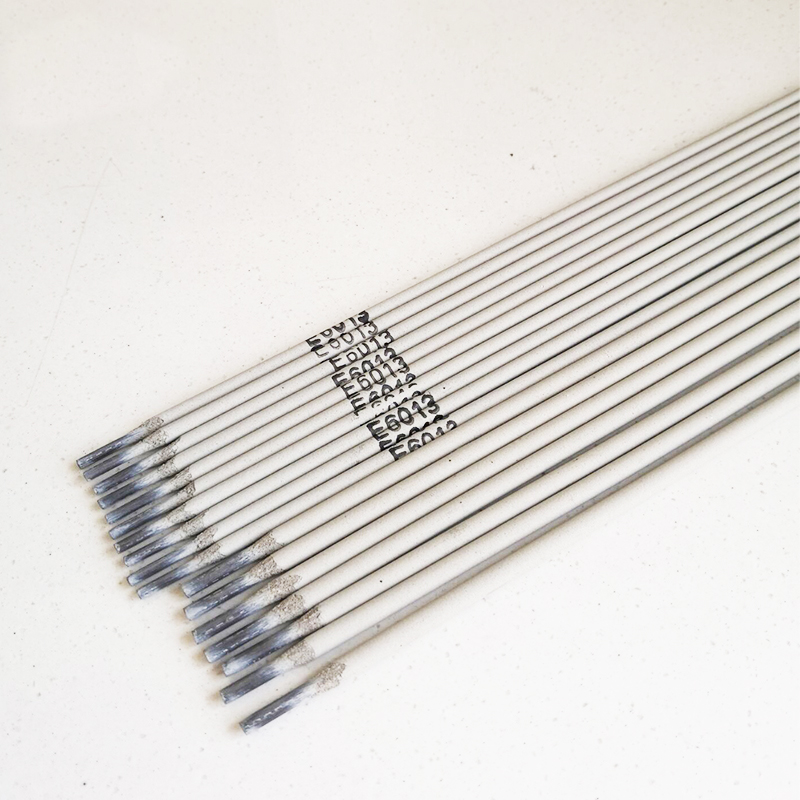

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025