Manufacturers of 7018 5/32 Welding Rods in China for High-Quality Welding Solutions

Understanding China’s 7018 5/32 Welding Rods and Their Manufacturers

Welding rods are essential tools in the field of metalworking, providing the necessary materials to join metal pieces together effectively. Among the various types available, the 7018 welding rod stands out due to its versatility and performance. Specifically, the 5/32 inch variant has gained popularity among professionals for its excellent features. Let's explore the characteristics of these welding rods and the manufacturers in China who produce them.

What are 7018 Welding Rods?

7018 welding rods are low-hydrogen electrode rods commonly used in Shielded Metal Arc Welding (SMAW). The number 7018 indicates the welding rod's properties - The first two digits 70 signify a minimum tensile strength of 70,000 psi, - The 1 indicates suitable for all positions of welding, - The 8 denotes low hydrogen content, which is crucial in minimizing the risk of cracking in the weld.

The 5/32 inch (or approximately 4 mm) diameter is particularly favored for medium-thickness materials and is ideal for structural steel applications, ensuring strong and durable welds.

Advantages of Using 7018 Welding Rods

One of the primary benefits of using 7018 rods is their ability to produce smooth and clean welds. With low spatter and excellent arc stability, welders can achieve high-quality joins without compromising the integrity of the materials being welded. These rods also have good impact toughness and low-temperature ductility, making them suitable for use in various environmental conditions.

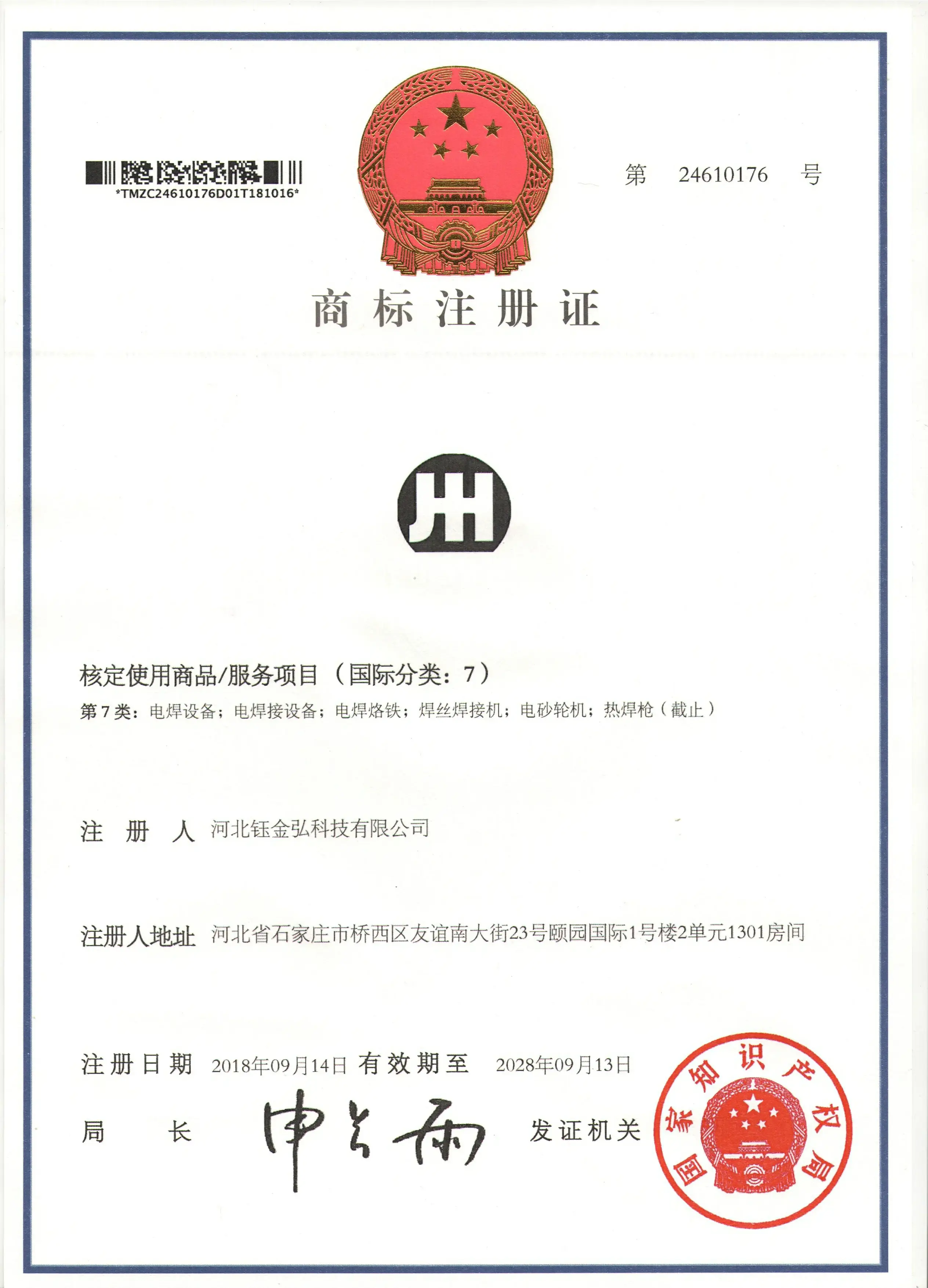

china 7018 5/32 welding rods manufacturers

Moreover, the low hydrogen content of 7018 welding rods plays a pivotal role in reducing the chance of porosity and hydrogen-induced cracking, which can significantly affect the lifespan of the weld joint. As a result, they are widely used in critical applications, including construction, pressure vessels, and pipelines.

Chinese Manufacturers of 7018 Welding Rods

China is home to numerous manufacturers specializing in the production of welding rods, including the highly sought-after 7018 5/32 welding rods. These manufacturers employ advanced technology and stringent quality control measures to ensure that their products meet international standards. Many factories are ISO certified, indicating a commitment to quality and consistency.

Some notable manufacturers have earned reputations for reliability and innovation in the welding sector. They invest in research and development to improve their products, ensuring that they keep up with the evolving demands of the market.

Conclusion

In conclusion, the 7018 5/32 welding rods produced by manufacturers in China are an excellent choice for professionals seeking quality and reliability in their welding tasks. With their robust characteristics and various applications across industries, these rods not only enhance the efficiency of welding processes but also ensure the durability and strength of the welded joints. As the demand for high-quality welding supplies continues to grow, Chinese manufacturers remain at the forefront, contributing significantly to this critical sector. Whether for industrial use or construction projects, the 7018 welding rods from China serve as a testament to the country's capability in producing essential welding materials for global markets.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025