China Aluminum Arc Welding Rod Manufacturers and Suppliers for Quality Welding Solutions

The Evolution and Impact of China’s Aluminum Arc Welding Rod Factories

Aluminum has emerged as one of the most vital materials in various industries due to its lightweight, corrosion resistance, and excellent mechanical properties. As a result, the role of aluminum arc welding rods has become increasingly significant. In China, the evolution of aluminum arc welding rod factories reflects not only advancements in manufacturing processes but also the growing demand for high-quality welding materials to support various industrial applications.

The Basics of Aluminum Arc Welding

Aluminum arc welding is a process that utilizes an electric arc to melt aluminum and create a robust joint between two aluminum pieces. The use of welding rods in this method is paramount, as they contribute to the welding arc’s stability and help manage the heat required for the process. The rods must possess specific qualities, including a compatible alloy composition, a smooth diameter for better arc control, and a coating that provides clean shielding to the molten weld pool.

Growth of Manufacturing Facilities

In recent years, China has established itself as a leading manufacturer of aluminum arc welding rods. The growth of these factories can be attributed to several factors, including modernization of production techniques, availability of raw materials, and a booming domestic and international market. With technological advancements, many factories are now employing automated systems that enhance efficiency and precision in the manufacturing process.

Chinese manufacturers have invested heavily in research and development to innovate their product lines. By incorporating advanced materials and specialized coatings, these manufacturers ensure the delivery of rods that meet international standards and cater to various welding processes, including MIG, TIG, and stick welding.

The Environmental Considerations

The rise of aluminum arc welding rod factories in China has not been without its challenges. Environmental concerns regarding production processes have led to increased scrutiny from both governmental and non-governmental organizations. In response, many factories have adopted greener practices, such as waste reduction, recycling of materials, and utilization of cleaner energy sources. These efforts align with China's broader commitment to sustainable industrial practices and reducing carbon emissions.

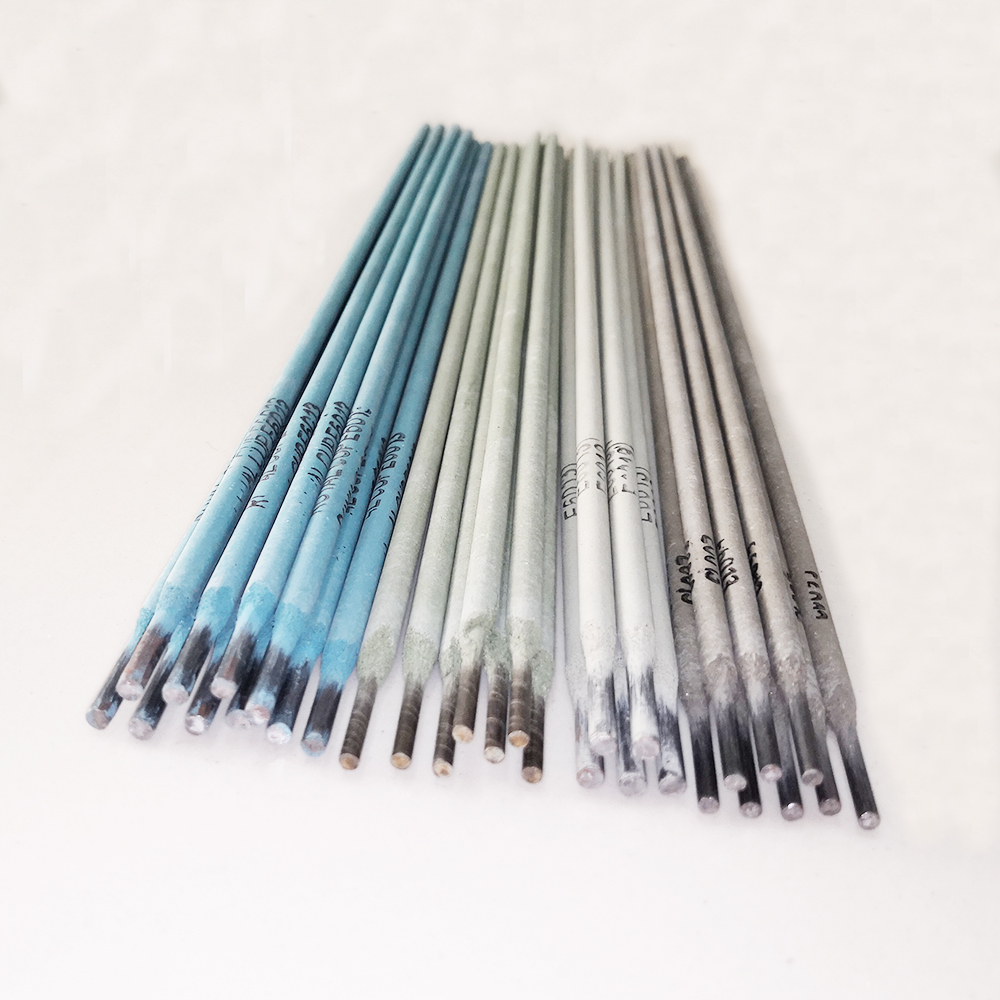

china aluminum arc welding rod factories

Factories are increasingly focusing on developing eco-friendly welding rods that not only perform well but also minimize harmful environmental impacts. Research into using alternative materials and coatings is ongoing, aiming to produce rods that are not only effective but also more environmentally friendly.

Quality Assurance and Global Standards

To remain competitive in the global market, Chinese aluminum arc welding rod manufacturers must adhere to international standards such as ISO and ASME. Many factories are now implementing strict quality control measures throughout the production process, from sourcing raw materials to the final product testing. These quality assurance protocols ensure that the welding rods produced can withstand rigorous industrial applications while meeting safety and performance standards.

Chinese manufacturers often collaborate with international clients to better understand their needs and requirements. This customer-centric approach aids in the design and production of specialized welding rods tailored for specific applications, thereby expanding market opportunities and fostering long-term partnerships.

Future Trends

Looking ahead, the future of aluminum arc welding rod factories in China seems promising. As industries such as aerospace, automotive, and construction continue to demand high-quality welding materials, the factories are poised to scale operations further. Innovations in materials science, along with advancements in welding technology, will drive the evolution of new products that enhance welding efficiency and performance.

Moreover, the ongoing shift towards digitization in manufacturing processes—known as Industry 4.0—promises to revolutionize how these factories operate. The integration of smart technologies and data analytics will enable manufacturers to optimize production efficiency, reduce waste, and enhance product quality.

Conclusion

In summary, China’s aluminum arc welding rod factories are a vital component of the global industrial landscape. Their commitment to quality, sustainability, and innovation positions them well to meet the growing demands of various industries. Through continued investment in technology and eco-friendly practices, these factories will not only contribute to the economy but also play a crucial role in shaping the future of welding technologies.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025