china welding electrodes 6013 7018 factories

The Importance of China Welding Electrodes Focus on E6013 and E7018 Factories

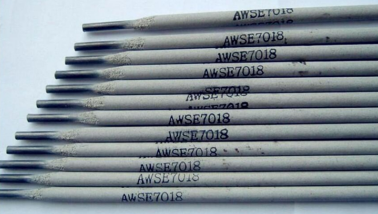

Welding is an essential process in various industries, from construction to manufacturing. One of the critical components that facilitate solid and durable welds is welding electrodes. Among the numerous types available, E6013 and E7018 electrodes stand out due to their specific properties and applications. Several factories in China specialize in producing these electrodes, significantly contributing to the global welding supply chain.

Understanding E6013 and E7018 Electrodes

E6013 electrodes are typically utilized in light to medium structural welding applications. Known for their versatility, ease of use, and the ability to weld in all positions, these electrodes produce a smooth, stable arc and minimal spatter, making them ideal for various steel constructions. The flux coating of E6013 contributes to excellent bead appearance, which is vital for aesthetic welding finishes.

On the other hand, E7018 electrodes are classified as low-hydrogen electrodes. These are commonly used in critical structural applications that require high strength and ductility. E7018 electrodes can provide superior mechanical properties and are mainly used for welding higher-strength steels. The low hydrogen content minimizes the risk of hydrogen-induced cracking, particularly when working with high-stress components.

The Role of Chinese Factories in Production

China has emerged as a significant player in the global welding electrodes market, thanks to its extensive manufacturing capabilities and advanced technology

. Factories across the country are equipped with state-of-the-art machinery that enables them to produce high-quality welding electrodes that meet international standards.Chinese manufacturers have invested in research and development to improve the formulations and characteristics of their electrodes. For instance, many factories focusing on E6013 and E7018 electrodes have developed unique formulations that enhance arc stability, reduce spatter, and improve overall weld quality. This innovation enables them to offer products that appeal to both domestic and international markets.

china welding electrodes 6013 7018 factories

Quality Control and Standards

Quality control is paramount in the manufacturing of welding electrodes. Chinese factories adhere to stringent quality assurance processes to ensure that every batch produced meets industry standards. Most factories are ISO certified and follow guidelines that comply with the American Welding Society (AWS) and other relevant standards.

These factories conduct comprehensive testing on their products, including mechanical property assessments, arc stability evaluations, and metallurgical analysis. Such rigorous testing guarantees that the E6013 and E7018 electrodes they produce can withstand demanding applications and deliver reliable performance.

Global Impact

The production of E6013 and E7018 electrodes in China significantly impacts the global welding industry. With competitive pricing and a commitment to quality, Chinese electrodes have found their way into numerous projects worldwide. From infrastructure development in emerging economies to high-tech projects in developed nations, the influence of Chinese-made electrodes is increasingly noticeable.

Moreover, the rise of e-commerce and global supply chain logistics has made it easier for international customers to source these electrodes directly from Chinese manufacturers. This accessibility not only helps in reducing costs but also ensures that customers receive products tailored to their specific needs, enhancing overall satisfaction.

Conclusion

The factories producing E6013 and E7018 welding electrodes in China play a crucial role in the global market. By focusing on quality, innovation, and adherence to international standards, these manufacturers are not only meeting the current demands but also paving the way for future advancements in welding technology. As industries continue to grow and evolve, the expertise and products from Chinese welding electrode factories will remain integral to successful welding applications worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025