Suppliers of ER70S-6 Welding Wire for Quality Welding Solutions and Applications

The Importance of ER70S-6 Welding Wire Suppliers in Modern Welding Applications

In the world of welding, the choice of materials and supplies can greatly influence the quality and durability of the final product. One such essential material is ER70S-6 welding wire, a popular choice among welders for its versatility and performance in a variety of applications. To ensure that projects run smoothly and meet industry standards, sourcing high-quality ER70S-6 welding wire from reliable suppliers becomes crucial.

ER70S-6 is a type of gas-shielded solid welding wire that is primarily used for welding mild steel and some low-alloy steels. Its composition includes high levels of manganese and silicon, which not only enhance the wetting and flow of the molten weld pool but also improve the wire's ability to tolerate surface contaminants like rust and mill scale. This makes it particularly desirable in construction, manufacturing, and repair applications where surface preparation may be less than optimal.

The Importance of ER70S-6 Welding Wire Suppliers in Modern Welding Applications

One of the key considerations when choosing an ER70S-6 welding wire supplier is their adherence to industry standards and certifications. A good supplier should provide wires that are compliant with the American Welding Society (AWS) A5.18 specification, which governs the classification and performance of welding wires. This not only guarantees the quality of the product but also assures customers that they are getting materials suitable for professional-grade applications.

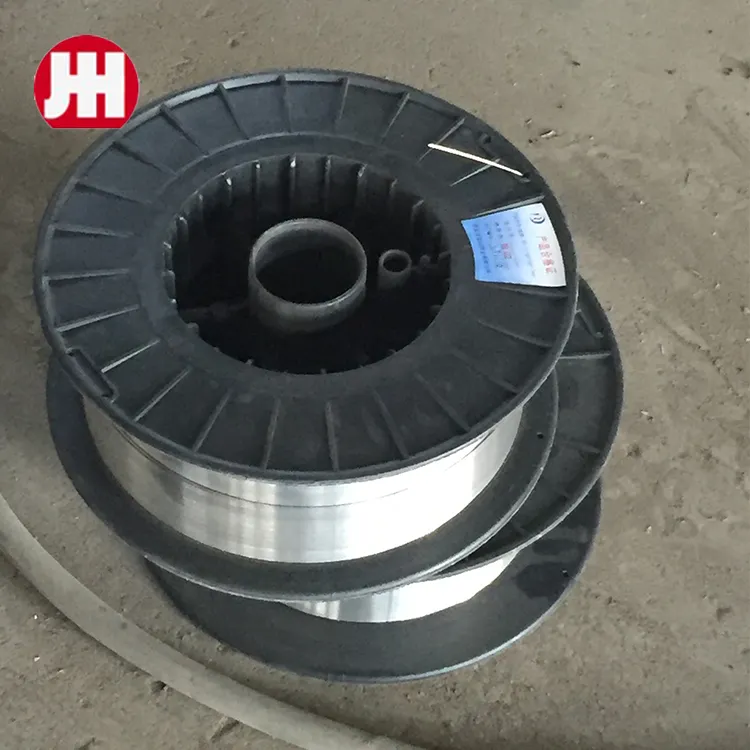

er70s-6 welding wire suppliers

Furthermore, a reliable supplier should also offer a range of diameters and spool sizes of ER70S-6 welding wire to accommodate various welding techniques and equipment. Whether you're using MIG welding, TIG welding, or pulsed arc welding, having the right size and type of welding wire is essential for achieving optimal results.

In addition to quality, another crucial aspect to consider is the supplier’s capabilities in logistics and customer service. A reputable supplier should have an efficient distribution network to ensure timely delivery of products. Welding projects often operate under tight deadlines, and delays in obtaining supplies can lead to increased costs and project setbacks. Therefore, suppliers who can guarantee quick turnaround times are invaluable to welding professionals.

Moreover, strong customer service is vital. Welding professionals may require technical support or guidance in selecting the appropriate products for specific applications. Suppliers that offer knowledgeable customer service personnel can help customers make informed decisions, ensuring that they achieve the best possible results in their welding projects.

Price is another pivotal factor in selecting a welding wire supplier. While it is essential to find competitive pricing, it is equally important to verify that the lower cost does not come at the expense of quality. Striking a balance between cost and quality should be a priority for welders to avoid future issues related to weld integrity.

In conclusion, the role of ER70S-6 welding wire suppliers is fundamental to the success of various welding applications. By choosing suppliers that prioritize quality, compliance with industry standards, efficient logistics, and excellent customer service, welding professionals can ensure the reliability and efficiency of their projects. As demand for skilled welders and reliable materials continues to grow, the importance of selecting the right ER70S-6 welding wire supplier remains a critical consideration in the welding industry.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025