High-Quality MIG Wire Supplier in China | Reliable Welding Solutions

The Growing Demand for MIG Wire from China Suppliers

As industries worldwide continue to evolve, the demand for high-quality welding materials has surged, particularly in the manufacturing, automotive, and construction sectors. Among these materials, MIG (Metal Inert Gas) wire has emerged as a crucial component for efficient and effective welding processes. China, with its robust manufacturing capabilities and competitive pricing, has established itself as a key supplier of MIG wire on the global stage.

Understanding MIG Wire

MIG wire is used for gas metal arc welding (GMAW), a popular welding technique that involves a continuous feed of filler metal delivered through a welding gun. The process utilizes an inert gas shield to protect the weld pool from contamination, leading to strong and quality welds. The choice of MIG wire is essential, as it directly affects the welding process's efficiency, the quality of the weld, and the overall productivity of manufacturing operations.

Why China?

China has become a dominant player in the supply of MIG wire for several reasons

1. Cost-Effective Production Chinese manufacturers benefit from lower labor costs and a well-established supply chain, allowing them to produce MIG wire at competitive prices. This affordability makes Chinese MIG wire an attractive option for businesses looking to cut costs without compromising quality.

2. High-Quality Standards Many Chinese suppliers adhere to international quality standards, providing products that are reliable and meet the specifications set forth by industries worldwide. Advanced technology and modern manufacturing processes contribute to the production of superior MIG wires that cater to diverse welding needs.

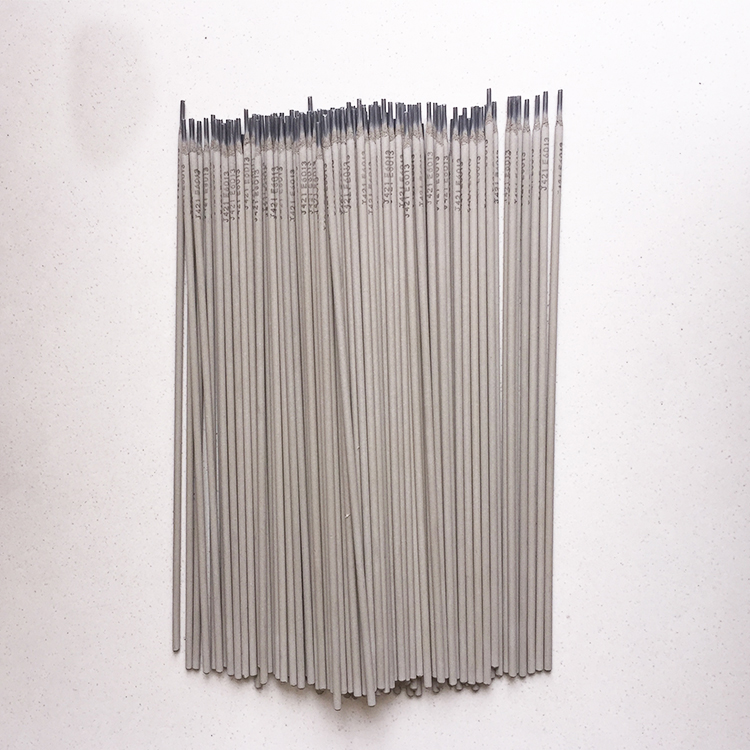

mig wire china supplier

3. Diverse Product Range Chinese suppliers offer a wide variety of MIG wire types, including solid and cored wires suitable for various applications such as steel, stainless steel, and aluminum welding. This diversity allows manufacturers to find the exact product they need for their specific welding tasks.

4. Export Infrastructure Well-developed logistics and shipping networks enable Chinese suppliers to deliver MIG wire quickly and efficiently to global markets. This efficiency is crucial for manufacturers who require timely delivery of welding materials to maintain their production schedules.

Challenges and Considerations

While the advantages of sourcing MIG wire from China are substantial, potential buyers should also be aware of certain challenges. Quality control can sometimes be inconsistent among various suppliers, necessitating thorough research and due diligence before making a purchase. Engaging with suppliers who have established reputations and qualifications can mitigate these risks.

Another aspect to consider is the geopolitical landscape and trade policies that may affect import duties and tariffs. Companies should stay informed about regulatory changes that could impact the cost and availability of MIG wire.

Conclusion

In conclusion, the rising demand for MIG wire presents a significant opportunity for both suppliers and businesses looking for efficient welding solutions. China’s position as a key supplier of high-quality, cost-effective MIG wire makes it an attractive option for industries around the world. By understanding both the benefits and the challenges associated with sourcing MIG wire from China, companies can make informed decisions to enhance their welding operations. As the global manufacturing landscape continues to shift, the importance of reliable welding materials, particularly MIG wire, cannot be overstated.

-

2.5mm Stainless Steel Welding Rods High-Strength & Corrosion-ResistantNewsMay.08,2025

-

Premium 2.5mm SS Welding Rods High-Strength Pipe Welding SolutionsNewsMay.08,2025

-

China Welding Steel Rods & Electrodes High-Quality Manufacturers & FactoriesNewsMay.07,2025

-

High-Strength Welding Rod 60 13 China Pipe Welding SupplierNewsMay.07,2025

-

Stainless Steel Gasless MIG Welding Wire Durable, Rust-ResistantNewsMay.07,2025

-

High-Quality Electric Welding Electrodo Wholesale Factory & SuppliersNewsMay.07,2025