steel welding wire manufacturers

The Importance and Evolution of Steel Welding Wire Manufacturers

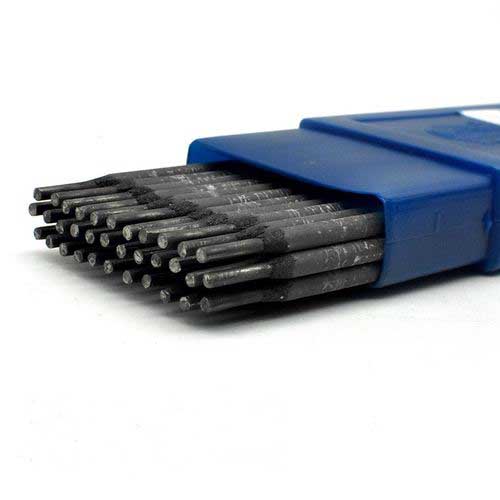

Welding is a critical process in construction, manufacturing, and art. At the heart of this process lies one of the most crucial components—the welding wire. Specifically, steel welding wire has become an indispensable resource in a variety of industries, and the manufacturers responsible for producing this essential material play a vital role in ensuring quality, performance, and safety.

Understanding Steel Welding Wire

Steel welding wire is designed to facilitate the joining of metal components using high heat to melt the wire and base materials. It is paramount in processes such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, where the wire acts as a filler material, bridging gaps between pieces being joined. The wire is manufactured in various grades and specifications, depending on the intended application. Common types include solid wire, flux-cored wire, and stainless steel wire, each tailored to suit specific welding methods or the properties required for the task at hand.

The Role of Manufacturers

Steel welding wire manufacturers are pivotal in dictating the quality and characteristics of the final product. They leverage advanced technology and meticulous processes to create welding wire that can withstand high temperatures and stress, ensuring a durable bond between metals. These manufacturers often conduct rigorous testing to meet industry standards, resulting in products that are reliable under various conditions.

Quality assurance is one of the paramount responsibilities of welding wire manufacturers. They must ensure that their products can support heavy loads and endure dynamic environmental conditions. A poorly manufactured wire can lead to structural failures, which is why manufacturers adhere to international standards like ASTM and ISO. By achieving certifications and ensuring compliance, manufacturers help prevent potential welding-related accidents.

Technological Advances

steel welding wire manufacturers

In recent years, the steel welding wire manufacturing industry has seen significant technological advancements. Automation and robotics have improved production efficiency while also minimizing human error. Modern manufacturers often utilize computer-controlled processes to create precise specifications, resulting in superior product consistency.

Additionally, the development of new materials and alloy compositions has expanded the capabilities of steel welding wires. For instance, companies are now producing wires that enhance corrosion resistance or provide better performance in high-temperature applications. These innovations cater to diverse industries, including construction, automotive, aerospace, and energy.

Global Market Trends

The global market for steel welding wire is anticipated to grow significantly, fueled by the rising demand in numerous sectors. The construction industry, driven by urbanization and infrastructure development, is a major consumer. Similarly, the automotive sector’s focus on lightweight and robust materials is spurring innovation in welding techniques and materials.

Moreover, as manufacturers globally adopt eco-friendlier practices, those producing steel welding wire are seeking to reduce waste and improve energy efficiency. Sustainable practices are becoming more prominent in the industry, aligning with global trends toward environmental responsibility.

Conclusion

Steel welding wire manufacturers are at the forefront of the welding industry, providing essential materials that underpin the integrity of countless structures and products. With advancements in technology and a growing emphasis on quality and sustainability, these manufacturers are not just suppliers but vital partners in the modernization of welding practices across various industries. As the demand for high-quality welding wires continues to rise, the role of these manufacturers will only increase in significance, driving progress and innovation in the sector. Their contributions to the safety and durability of welded joints cannot be overstated, marking them as crucial players in the world of construction and manufacturing.

-

Best 6013 Welding Electrode Price Durable Rods & Bulk DiscountsNewsMay.22,2025

-

E71T-1 & E71T-11 Welding Wire Specs High-Strength Flux-Cored WireNewsMay.22,2025

-

Galvanized Steel Welding Rods & Flux Core Wires Anti-Rust SolutionsNewsMay.22,2025

-

Premium Stainless TIG Electrodes High-Quality Welding SolutionsNewsMay.21,2025

-

E6013 3/32 Electrodes Wholesale Manufacturers - Durable & AffordableNewsMay.21,2025

-

E71TGS Welding Wire High-Strength Flux Core for Durable JointsNewsMay.20,2025