Top Manufacturers of Gasless Aluminum MIG Welding Wire for Wholesale Supply

The Growing Demand for Wholesale Gasless Aluminum MIG Wire Manufacturers

In the realm of welding, aluminum is a favored material for many industries due to its lightweight, corrosion-resistant properties, and versatility. With the advent of advanced welding technologies, gasless aluminum MIG wire has emerged as a significant development in welding materials. This article explores the trends and demands surrounding wholesale gasless aluminum MIG wire manufacturers and the growing significance of this product in the welding industry.

Understanding Gasless Aluminum MIG Wire

Gasless aluminum MIG wire is specially designed for metal inert gas (MIG) welding without the need for an external gas supply. This feature makes it particularly appealing for fieldwork and locations where traditional shielding gases are either impractical or impossible to use. Gasless aluminum welding wires typically use a flux core that protects the weld pool from atmospheric contamination, providing clean and strong welds even in challenging environments.

Rising Industry Demand

As the construction, automotive, aerospace, and manufacturing industries expand, the demand for high-quality aluminum welding solutions also rises. Gasless aluminum MIG wire is becoming increasingly popular due to its ease of use and flexibility, especially in outdoor and windy conditions where shielding gases can be displaced. With the ongoing trend towards lightweight materials for improved fuel efficiency and performance, aluminum’s prominence in industries is expected to grow, driving the need for effective welding solutions.

Role of Wholesale Manufacturers

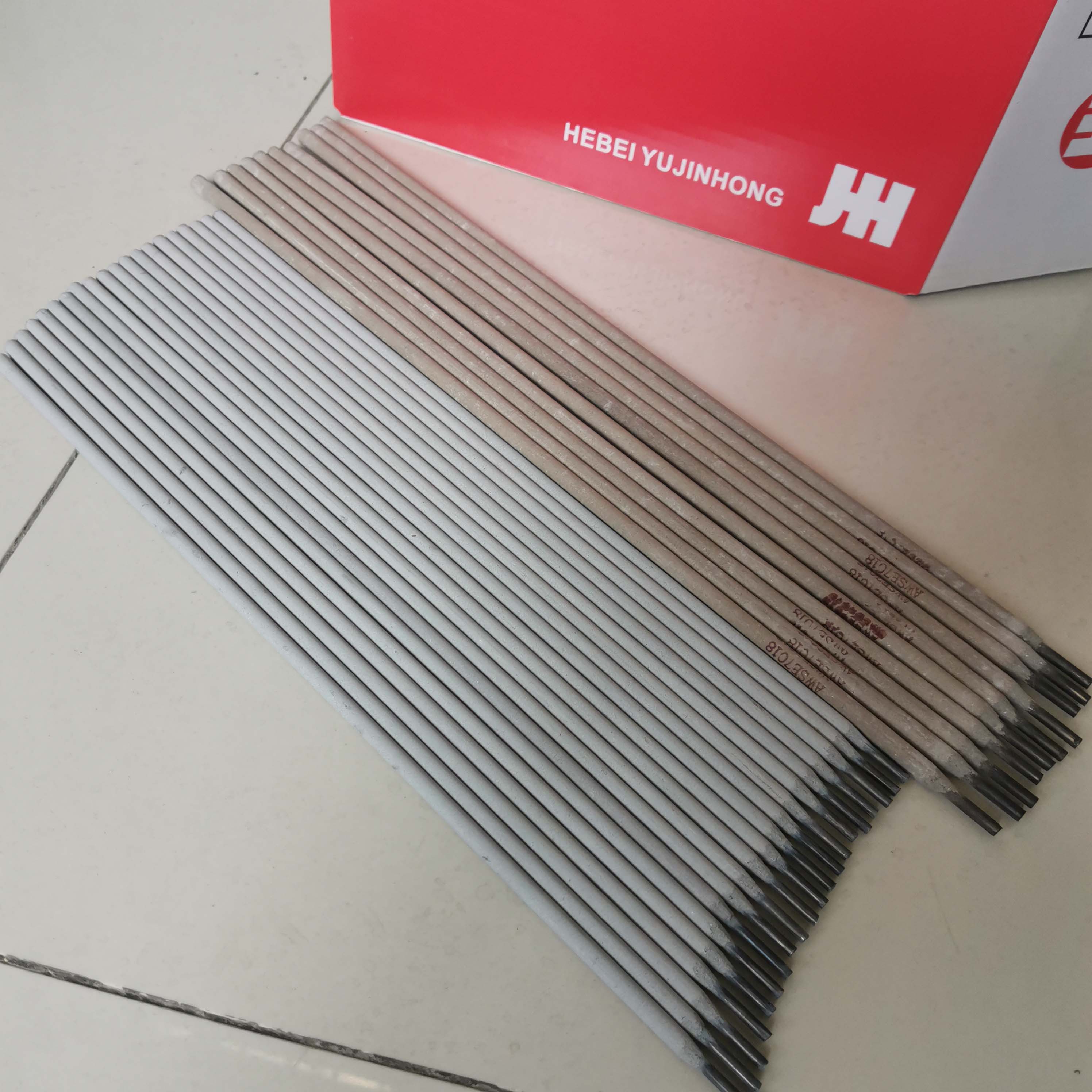

wholesale gasless aluminum mig wire manufacturers

Wholesale manufacturers of gasless aluminum MIG wire play a crucial role in meeting this increasing demand. They provide high-quality products at competitive prices, serving various clients, from large corporations to small-scale fabricators. These manufacturers ensure that their products comply with industry standards, guaranteeing reliability and performance.

Moreover, wholesale manufacturers often provide a range of wire diameters and alloy compositions, allowing welders to choose the right product for their specific applications. This customization is vital in industries like automotive and aerospace, where precision and material compatibility are paramount.

Quality Assurance and Innovations

With the rise in competition among manufacturers, quality assurance has become a focal point. Leading gasless aluminum MIG wire manufacturers invest in advanced production technologies and continuous quality control processes. This commitment to quality not only enhances product reliability but also promotes safety in the welding workplace.

In addition to quality, innovation is key in this industry. Manufacturers are continuously exploring new formulations for flux-cored wires, which can lead to better performance, improved weld appearance, and reduced spatter. As technology advances, manufacturers are also looking into eco-friendly options and practices, which resonate with the global shift toward sustainability.

Conclusion

In conclusion, the market for wholesale gasless aluminum MIG wire manufacturers is on a trajectory of growth, driven by the increasing use of aluminum across various industries and the need for efficient welding solutions. This product's adaptability and ease of use make it indispensable for both professional and amateur welders, especially in challenging working conditions. As manufacturers prioritize quality and innovation, we can expect advancements that will further enhance the performance of gasless aluminum MIG wire, securing its place as a vital component in future welding applications. The collaboration between manufacturers and end-users will be essential in realizing the full potential of this versatile welding material.

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025