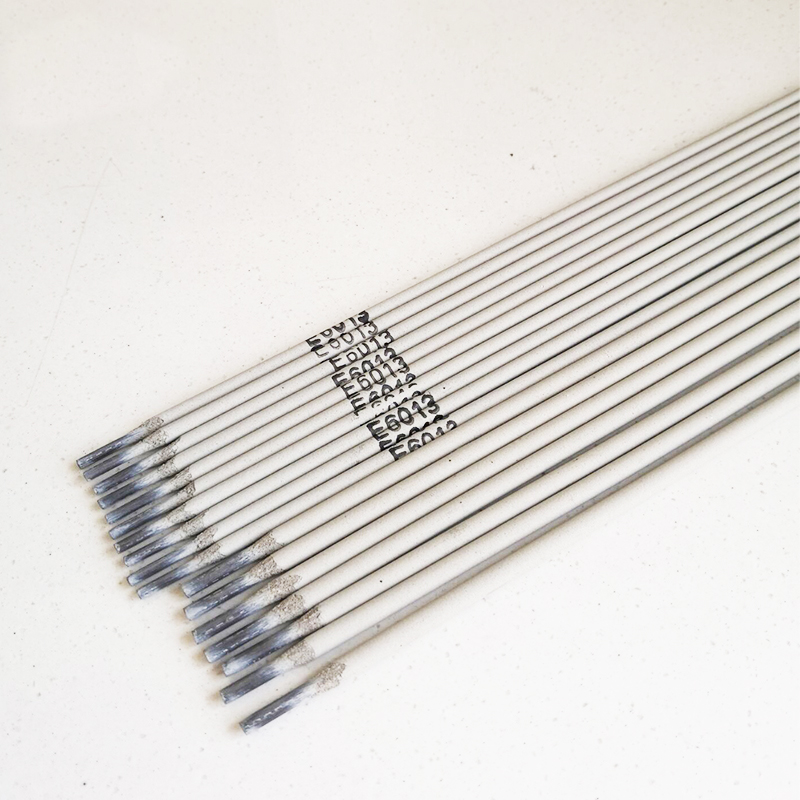

welding electrode e 6013 factories

Understanding E6013 Welding Electrodes A Factory Perspective

Welding is an essential process in various industries, ranging from construction to manufacturing, and the choice of electrode can significantly impact the quality of the weld. Among the many types of welding electrodes available, the E6013 electrode stands out for its versatility and ease of use, making it a popular choice in many factories around the world.

What is E6013?

The E6013 electrode is a type of coated electrode used in arc welding, specifically designed for mild steel. The classification E6013 reveals crucial information about its properties the 'E' indicates that it is an electric arc welding electrode; the '60' signifies a minimum tensile strength of 60,000 psi, and '1' refers to its welding position capabilities - it can be used in all positions, including flat, horizontal, vertical, and overhead. The last '3' indicates the type of coating used, which affects the stability of the arc and the quality of the weld.

Benefits of E6013 Electrodes

One of the primary reasons E6013 electrodes are favored in factories is their ease of use and forgiving nature. They produce a smooth, stable arc and generate less spatter compared to other types of electrodes. This makes them suitable for both beginners and experienced welders. Additionally, the E6013 can create a clean weld with minimal cleanup required, which is particularly advantageous in high-production environments.

welding electrode e 6013 factories

Manufacturing Process

Factories that produce E6013 electrodes utilize advanced techniques to ensure consistent quality. The raw materials, including iron powder and various alloys, are carefully selected and mixed. The manufacturing process typically involves extrusion to shape the electrodes, followed by a coating application that is crucial for providing the electrode its unique properties. Quality control is essential at every stage of production to guarantee the electrodes meet industry standards.

Applications in Industry

E6013 electrodes are widely used in various applications, including automotive repair, machinery fabrication, and general construction work. Their ability to perform well on thin materials makes them a favorite amongst welders working in tight spaces or on delicate structures.

In conclusion, E6013 welding electrodes are a vital component in modern manufacturing practices. Their versatility, ease of use, and efficiency make them indispensable tools in factories around the globe, contributing to the integrity and strength of countless welded structures.

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025