wholesale 1 16 welding rod manufacturers

The Wholesale Market for Welding Rods Trends and Manufacturers in 2016

In the industrial landscape, welding plays a crucial role in various sectors such as construction, automotive, manufacturing, and maintenance. One key component that enables effective welding processes is the welding rod. In 2016, the wholesale market for welding rods witnessed significant changes, driven by evolving technologies, increased demand from various industries, and a competitive landscape of manufacturers.

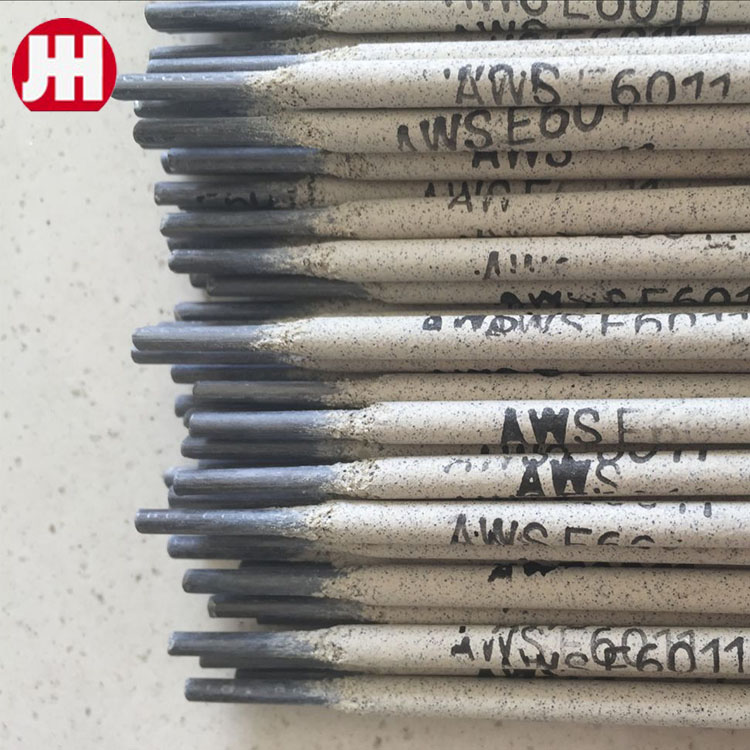

Welding rods, also known as welding electrodes, are essential in the welding process as they provide the filler material needed to join two or more metal parts. There are various types of welding rods available in the market, including coated rods, solid rods, and flux-cored wires, each designed for specific applications and welding methods. In 2016, the demand for these rods continued to rise, fueled by global economic recovery and increased investments in infrastructure projects.

Market Dynamics and Trends

The welding rod market in 2016 was characterized by notable trends that shaped its landscape. First and foremost was the rising demand from emerging economies, particularly in Asia-Pacific and Latin America. Countries like China and India continued to invest heavily in infrastructure and manufacturing, fueling the demand for high-quality welding materials. As a result, manufacturers who could provide reliable and innovative products found themselves at a competitive advantage.

Additionally, there was a marked shift towards automation and innovation in the welding process. Many manufacturers started to invest in research and development to create more efficient welding rods that could enhance productivity and reduce costs for end-users. The introduction of advanced materials and technologies, such as low-hydrogen electrodes and composite welding rods, became increasingly common, transforming the product offerings within the wholesale market.

Key Players and Manufacturers

The welding rod market in 2016 was characterized by the presence of numerous manufacturers who contributed to the overall supply chain. Some of the key players included established companies with a strong global presence, such as Lincoln Electric, ESAB, and Hobart Brothers, alongside numerous regional manufacturers who catered to specific markets.

1. Lincoln Electric A global leader in the welding industry, Lincoln Electric offered a comprehensive range of welding rods and solutions. Their commitment to innovation and quality made them a preferred choice among businesses in various sectors.

wholesale 1 16 welding rod manufacturers

2. ESAB Known for its pioneering role in the welding and cutting industry, ESAB provided an extensive range of products, including various types of welding rods designed for different applications. Their focus on customer service and technological advancements set them apart from competitors.

3. Hobart Brothers Hobart Brothers specialized in manufacturing welding consumables and equipment. Their expertise in metallurgy enabled them to produce high-quality rods that met the specific needs of their clientele.

In addition to these global players, the market saw a rise in local manufacturers who offered competitive pricing and tailored solutions to suit regional demands. This diversification increased competition within the wholesale market, leading to better pricing and innovative products for end-users.

Challenges and Opportunities

While the welding rod market exhibited robust growth in 2016, it also faced challenges. The fluctuating prices of raw materials, coupled with stringent regulations and environmental concerns, posed difficulties for manufacturers. Additionally, the industry was under pressure to find sustainable practices while maintaining productivity and profitability.

However, with challenges come opportunities. The growing emphasis on sustainable welding practices opened avenues for manufacturers to innovate. Companies that adopted eco-friendly materials and processes began to attract environmentally-conscious customers. Furthermore, as industries moved towards more automated and efficient practices, manufacturers had the opportunity to create specialized products that cater to these modern workflows.

Conclusion

The wholesale market for welding rods in 2016 was marked by a combination of innovation, increased demand, and fierce competition among manufacturers. As the industry moved forward, the key players that adapted to changing demands, embraced technological advancements, and prioritized sustainability were poised to thrive. For businesses relying on welding processes, staying informed about trends and sourcing high-quality welding rods would remain critical in meeting production goals and ensuring operational success in the years to come.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025