Wholesale High-Quality Welding Electrode Wires for All Your Welding Needs

Understanding Wholesale Welding Electrode Wire A Comprehensive Guide

Welding is an essential process in various industries, including construction, automotive, and manufacturing. At the heart of this process lies the welding electrode wire, a critical component that determines the quality and efficiency of welds. This article will explore the importance of wholesale welding electrode wire, including its types, specifications, suppliers, and best practices for purchasing.

What is Welding Electrode Wire?

Welding electrode wire is a metal wire used in the welding process to join two or more pieces of metal together. The wire serves as a filler material that melts and fuses the base metals, creating a strong bond. Different types of welding processes, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding, utilize various types of electrode wires tailored to specific applications.

Types of Welding Electrode Wire

Welding electrode wires come in various forms, each designed for different welding processes and applications

1. MIG Welding Wire Typically made from mild steel, stainless steel, or aluminum, MIG welding wire is used in MIG welding. This wire is fed through a spool and is continuously melted during the welding process. MIG wires can be solid or flux-cored, offering versatility depending on the project requirements.

2. TIG Welding Electrode Unlike MIG welding, which uses a consumable wire, TIG welding utilizes a non-consumable tungsten electrode. However, filler rods can be added as needed. TIG welding is ideal for precise, high-quality welds on thin materials.

3. Stick Welding Electrodes Also known as SMAW (Shielded Metal Arc Welding), stick welding uses a consumable electrode coated in flux. As the electrode melts, the flux forms a shielding gas to protect the weld from contamination.

4. Flux-Cored Wires These are tubular wires filled with flux that creates a protective gas when heated. They can be used in both MIG and stick welding processes. Flux-cored wires are favored for outdoor welding due to their resistance to wind and atmospheric conditions.

Choosing the Right Welding Electrode Wire

When selecting welding electrode wire, several factors should be considered

- Material Compatibility Ensure the electrode wire matches the base metals being welded to achieve optimal results. - Welding Position Certain electrodes excel in specific positions (flat, horizontal, vertical, overhead), so choose accordingly. - Weld Quality Depending on the application, select electrodes that provide the desired penetration, bead appearance, and strength. - Ease of Use For beginners or less experienced welders, select wires that are easier to handle and provide forgiving results.

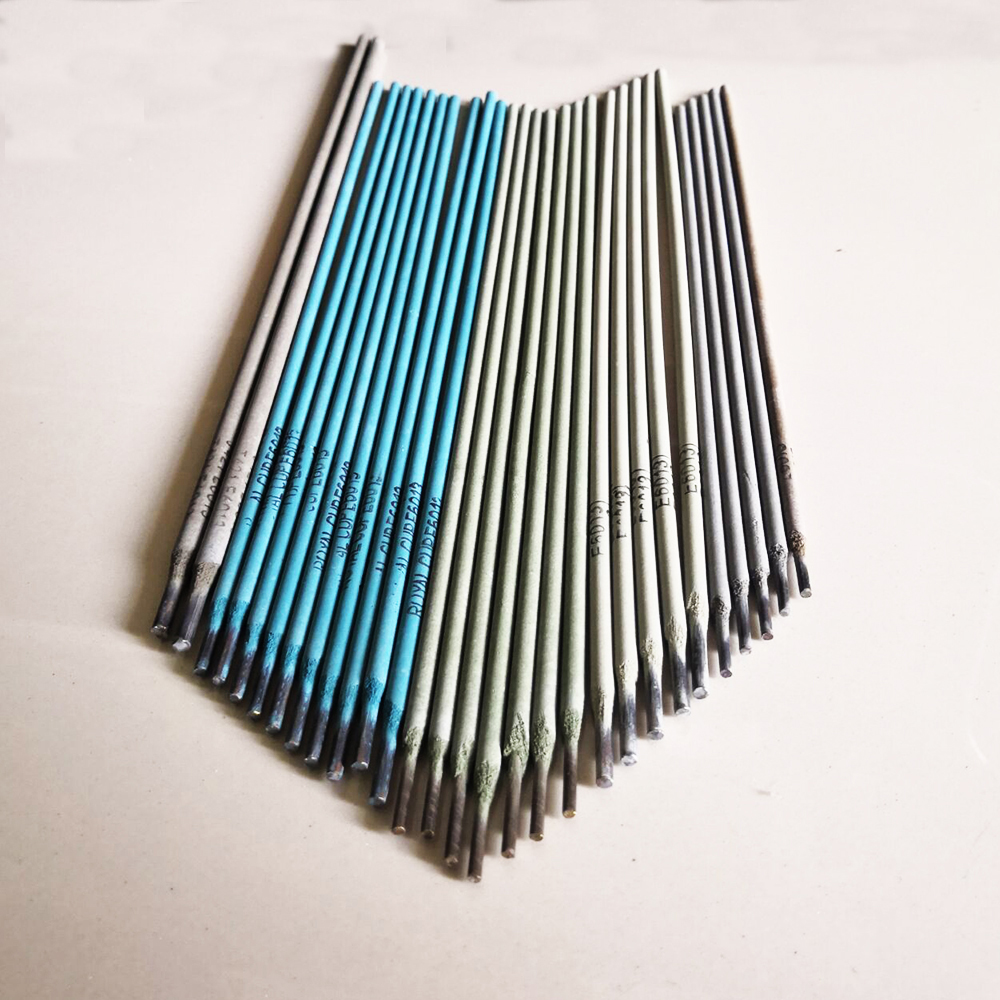

wholesale welding electrode wire

Wholesale Suppliers of Welding Electrode Wire

Buying welding electrode wire in bulk can significantly reduce costs and ensure a consistent supply for your projects. Here are a few pointers when looking for wholesale suppliers

1. Reputation Opt for suppliers with a good reputation in the market and positive reviews from previous customers. A reliable supplier will ensure quality products that meet industry standards.

2. Product Range Look for suppliers that offer a diverse range of welding electrodes to cater to different needs and applications. This diversity allows you to switch between electrodes without needing multiple suppliers.

3. Pricing and Discounts Wholesale suppliers often provide discounts based on purchasing volume. Be sure to compare prices from multiple suppliers to get the best deal.

4. Customer Support Choose suppliers that provide excellent customer support to help with any questions or issues related to your purchase. This support can be invaluable, especially for businesses that rely heavily on welding.

Best Practices for Purchasing Wholesale Welding Electrode Wire

1. Bulk Orders When placing orders, consider buying in large quantities, as this can lead to lower costs and ensure you have enough material for your projects.

2. Inventory Management Track your inventory to avoid running out of essential supplies. Implement a reorder point system to ensure that you replenish stock in a timely manner.

3. Quality Control Always conduct a quality check upon receiving your shipment to ensure that you received the correct wire and that it meets your specifications.

Conclusion

Wholesale welding electrode wire is vital for any welding business or enthusiast looking to optimize their processes and reduce costs. By understanding the different types of welding electrode wires available, knowing how to choose the right one, and finding a reliable supplier, you will position yourself to achieve superior welding results. Whether you’re working on small projects or large-scale industrial applications, investing in quality welding electrode wire is essential for maintaining high standards and productivity.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025