Wholesale MIG ER70S-6 Welding Wire Suppliers and Factories for Quality Products

An Overview of Wholesale Welding Wire Focus on MIG ER70S-6 Factories

Welding is an essential process in various industries, including construction, automotive, and manufacturing. Among the myriad of welding techniques, Metal Inert Gas (MIG) welding is widely appreciated for its versatility and efficiency. One of the most popular types of wires used in MIG welding is ER70S-6. This article delves into the wholesale aspect of MIG ER70S-6 welding wire, focusing on factories that specialize in its production and supply.

What is ER70S-6 Welding Wire?

ER70S-6 is a copper-coated, solid welding wire primarily used for welding low to mild carbon steels. The 'ER' stands for 'electrode required,' while '70' indicates the tensile strength of the weld metal in thousands of pounds per square inch (PSI). The 'S' denotes that it is a solid wire, and the '-6' indicates specific chemical composition and mechanical properties, particularly its ability to handle rust and scale on workpieces. This wire is particularly favored for its excellent arc stability, low spatter, and the ability to weld in various positions.

The Demand for ER70S-6 Welding Wire

The demand for ER70S-6 welding wire has surged owing to its extensive application across many sectors. Industries like shipbuilding, structural steel fabrication, and automotive manufacturing frequently use this type of wire due to its versatility and effectiveness in producing high-quality welds. As a result, factories producing ER70S-6 welding wire are becoming increasingly popular among wholesale distributors.

Factories Specializing in ER70S-6 Welding Wire

Wholesale suppliers often rely on dedicated factories to meet their ER70S-6 welding wire needs. These factories typically follow stringent quality standards and certifications to ensure that their products meet industry requirements. Here are some key characteristics of leading manufacturers in this space

1. Quality Assurance Top factories employ advanced quality control processes. They conduct metallurgical tests, tensile strength evaluations, and chemical composition analyses to ensure that the welding wire meets the ER70S-6 specifications. This ensures that the final product is reliable for professional welding applications.

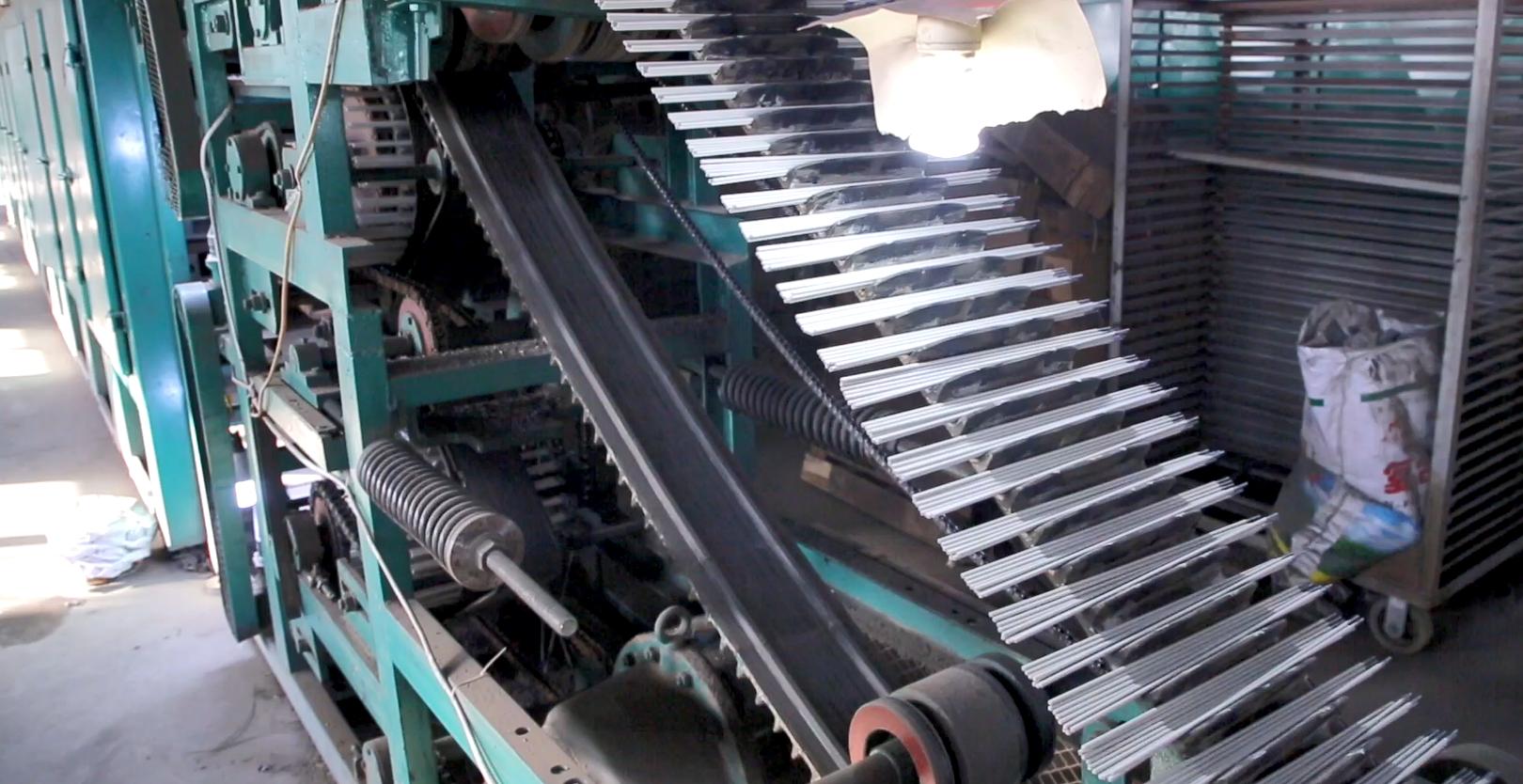

wholesale welding wire mig er70s-6 factories

2. Innovative Production Techniques Many factories are adopting cutting-edge machinery and production techniques that enhance efficiency and reduce costs. Automation, for example, is becoming more prevalent, enabling factories to increase output without compromising on quality.

3. Sustainable Practices These manufacturers are increasingly focused on sustainability, implementing eco-friendly practices in their production processes. This includes recycling scrap materials and reducing energy consumption, aligning with global standards for environmental stewardship.

4. Customization Options Leading factories often offer customization options, allowing wholesalers to specify diameter sizes, packaging, and batch delivery. This flexibility enables distributors to cater to diverse customer needs.

5. Global Supply Chains Many of these factories are part of global supply chains, providing access to varying markets. They often offer competitive pricing due to economies of scale, making them attractive to wholesalers looking to maximize their profits.

The Wholesale Market for ER70S-6 Wire

The wholesale market for ER70S-6 welding wire is dynamic and competitive. Distributors must keep abreast of market trends such as pricing fluctuations, shifts in demand, and advancements in welding technology. Building strong relationships with factories can lead to better pricing and priority access to products, which is essential for maintaining an edge in the market.

Establishing a reliable wholesale network is crucial. Wholesalers should consider factors such as lead times, customer service, and the factory's reliability. A strong partnership can ensure a smooth supply chain, allowing for timely delivery of products to their retail customers.

Conclusion

In summary, the wholesale market for ER70S-6 welding wire is characterized by rising demand, driven by its extensive applications across various industries. Factories specializing in this product are vital to the supply chain, offering high-quality, reliable, and innovative welding wire solutions. As industries evolve and new technologies emerge, the demand for durable and effective welding materials like ER70S-6 ensures that these factories will continue to play a crucial role in the global welding landscape. For wholesalers, establishing strong relationships with these manufacturers is key to success in this competitive market.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025