3 32 7018 welding rod suppliers

The Importance of Quality Welding Rods A Focus on 3% 2032 7018 Welding Rod Suppliers

In the world of welding, the choice of materials is critical to ensuring that projects are completed to the highest standards. Among the various types of welding rods available, the 3% 2032 7018 welding rod has gained significant popularity due to its excellent mechanical properties and versatility. Understanding the qualities of these welding rods and how to find reliable suppliers is essential for manufacturers and welders aiming for durability and strength in their welds.

Understanding 3% 2032 7018 Welding Rods

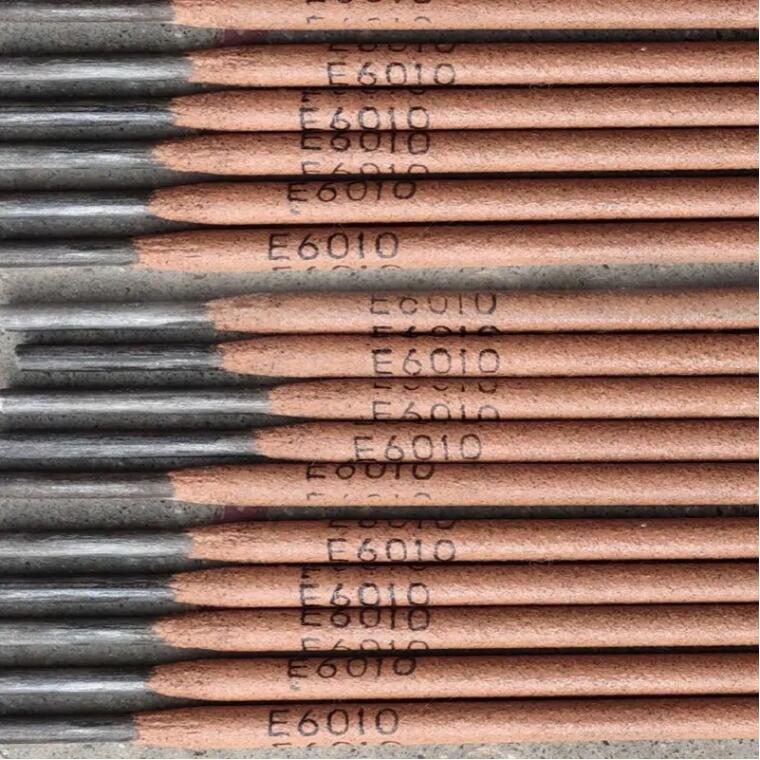

The 7018 welding rod belongs to the low hydrogen electrode family and is primarily used for shielded metal arc welding (SMAW). This type of rod is known for its excellent weldability, making it suitable for joining thick steel sections and for applications requiring high strength. The designation 3% 2032 refers to the specific alloying elements and their respective percentages within the rod, which enhance its performance attributes.

One of the most notable features of 7018 rods is their low hydrogen content, which significantly reduces the risk of hydrogen-induced cracking. This characteristic is particularly vital in high-stress applications, such as pressure vessels, various structural components, and heavy machinery. Additionally, the 3% alloying elements contribute to improved toughness and ductility, allowing fabrications to withstand diverse operational conditions.

The Role of Suppliers

When it comes to achieving quality welds, identifying dependable suppliers of 3% 2032 7018 welding rods is crucial. Quality assurance from suppliers can directly influence the overall integrity and performance of welding projects. Reputable suppliers ensure their products meet industry standards such as AWS (American Welding Society) guidelines, which helps guarantee that welders receive rods that are reliable and effective.

Here are several factors to consider when searching for quality welding rod suppliers

3 32 7018 welding rod suppliers

1. Certifications and Compliance Ensure that suppliers have the necessary certifications and comply with standards relevant to your industry. This compliance indicates that their products meet safety and quality requirements.

2. Product Quality Look for suppliers who provide detailed information about the composition and properties of their welding rods. High standards in manufacturing processes will generally result in better quality products.

3. Customer Support Good suppliers offer adequate support and can provide advice on product selection, usage, and troubleshooting. They should also be responsive to any concerns regarding their products.

4. Reviews and Reputation Researching customer reviews and testimonials can provide insight into a supplier's reliability and service quality. Opt for suppliers with a solid reputation within the welding community.

5. Price and Availability While cost is a significant factor, it shouldn't be the only determining aspect. Quality should not be sacrificed for price. Ensure that the supplier can consistently provide products as needed for your ongoing projects.

Conclusion

In conclusion, the selection of the right welding rod, particularly the 3% 2032 7018 welding rod, is pivotal for achieving high-quality welds in various applications. Understanding the rod characteristics and locating trustworthy suppliers can significantly contribute to the effectiveness and reliability of welding operations. By focusing on quality, compliance, and reliable service, welders can enhance the durability of their projects and ensure safe, long-lasting results.

As industries evolve and new technologies emerge, the importance of maintaining high standards in welding practices will only amplify. Therefore, investing time in selecting the right suppliers for 3% 2032 7018 welding rods will pay dividends in the long run, ensuring welders can tackle the challenges posed by modern engineering and construction demands. Robust partnerships with dependable suppliers not only streamline operations but ultimately foster a culture of quality and excellence within the welding profession.

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025