فبراير . 08, 2025 06:56

Back to list

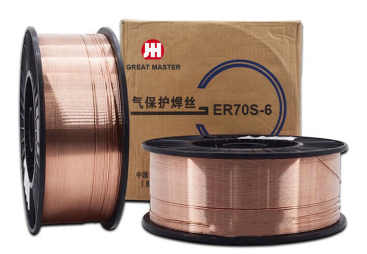

Copper Coated Welding Wire for carbon steel

Navigating the vast landscape of welding materials can be daunting, particularly in selecting the appropriate welding wire for various applications. Among the plethora of options, the 4043 welding wire stands out for its distinctive properties and widespread application in aluminum welding. This welding wire has forged a reputation for reliability underpinned by real-world experience, expertise, and a commitment to efficacy.

In terms of authoritativeness, the 4043 welding wire has been extensively reviewed and analyzed by industry specialists. Welding associations and standards bodies recognize it for its consistent performance and have included it in recommendations for specific applications, underpinning its credibility in professional circles. Trustworthiness is further established through certifications from leading industry standards such as the American Welding Society (AWS), which corroborates its adherence to rigorous testing and quality assurance processes. An additional layer of trustworthiness and reliability is provided by manufacturers who subject the 4043 welding wire to stringent quality inspections. These procedures ensure uniform diameter, consistent composition, and absence of impurities, factors that can significantly affect the quality of a weld. Such measures guarantee that users receive a product that performs as promised, fostering confidence in its application across delicate and demanding projects. Customer testimonials and independent reviews offer valuable insights into the practical benefits and minor caveats associated with 4043 welding wire use. For instance, operators commend its forgiving nature, allowing for minor adjustments during the welding process without sacrificing quality. However, some users note its limited suitability in high-temperature or high-strength applications, where an alternative alloy might be more appropriate. In conclusion, the 4043 welding wire distinguishes itself through a robust combination of adaptability, integrity, and proven expertise. It is an asset in the world of aluminum welding, consistently delivering quality results. Welding professionals and enthusiasts alike continue to trust and rely on it, supported by authoritative endorsements and extensive real-world validation. As a product, it aligns seamlessly with the demands of diversifying industries, catering to both current needs and future developments in welding technology.

In terms of authoritativeness, the 4043 welding wire has been extensively reviewed and analyzed by industry specialists. Welding associations and standards bodies recognize it for its consistent performance and have included it in recommendations for specific applications, underpinning its credibility in professional circles. Trustworthiness is further established through certifications from leading industry standards such as the American Welding Society (AWS), which corroborates its adherence to rigorous testing and quality assurance processes. An additional layer of trustworthiness and reliability is provided by manufacturers who subject the 4043 welding wire to stringent quality inspections. These procedures ensure uniform diameter, consistent composition, and absence of impurities, factors that can significantly affect the quality of a weld. Such measures guarantee that users receive a product that performs as promised, fostering confidence in its application across delicate and demanding projects. Customer testimonials and independent reviews offer valuable insights into the practical benefits and minor caveats associated with 4043 welding wire use. For instance, operators commend its forgiving nature, allowing for minor adjustments during the welding process without sacrificing quality. However, some users note its limited suitability in high-temperature or high-strength applications, where an alternative alloy might be more appropriate. In conclusion, the 4043 welding wire distinguishes itself through a robust combination of adaptability, integrity, and proven expertise. It is an asset in the world of aluminum welding, consistently delivering quality results. Welding professionals and enthusiasts alike continue to trust and rely on it, supported by authoritative endorsements and extensive real-world validation. As a product, it aligns seamlessly with the demands of diversifying industries, catering to both current needs and future developments in welding technology.

Latest news

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025