7018 Welding Electrode Manufacturing Facility Overview and Production Details

The Importance of 7018 Welding Electrode Factories in Modern Manufacturing

In the modern world of manufacturing and construction, welding is an essential process that ensures the structural integrity of countless applications. Among the various types of welding electrodes, the 7018 welding electrode is one of the most widely used due to its strength, versatility, and ease of use. This article delves into the significance of 7018 welding electrode factories, their contribution to quality welding practices, and their overarching impact on the manufacturing industry.

The Importance of 7018 Welding Electrode Factories in Modern Manufacturing

Welding electrode factories play a pivotal role in the production of 7018 electrodes. These factories employ advanced technologies and strict quality control measures to ensure that each electrode meets the industry standards. The manufacturing process typically involves the careful selection of raw materials, precise formulations for the coating, and meticulous attention to the electrode's diameter and length. During production, these factories employ various testing methodologies, such as tensile testing and impact testing, to validate the performance of the electrodes.

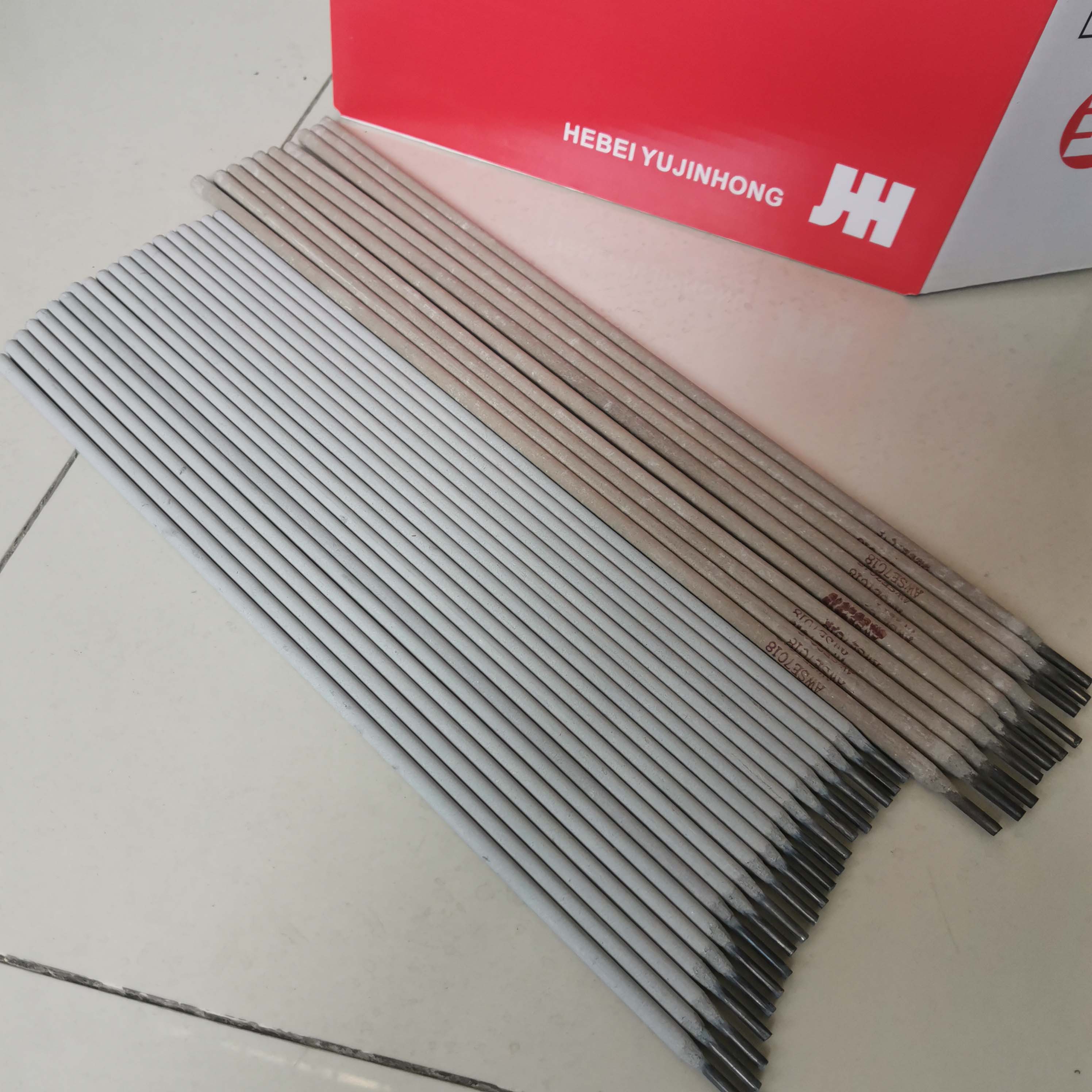

7018 welding electrode factory

One of the critical aspects of 7018 welding electrode factories is their contribution to safety in welding practices. Since the 7018 electrode is designed to reduce the release of hydrogen, it minimizes the risk of cracking often associated with high-stress applications. By ensuring the availability of high-quality electrodes, these factories help reduce accidents and enhance the overall safety of welding operations.

Furthermore, the innovations arising from 7018 welding electrode factories have a substantial impact on the industry's sustainability. Many factories are adopting environmentally friendly practices, such as recycling electrode materials and minimizing waste during production. This commitment not only reduces the carbon footprint associated with electrode manufacturing but also fosters a culture of sustainability within the welding community.

The demand for 7018 welding electrodes continues to grow, fueled by advancements in technology and an increasing need for high-quality welds in various industries, including automotive, aerospace, and construction. As the global market evolves, 7018 welding electrode factories are poised to adapt and innovate, ensuring that they meet the evolving needs of their customers while maintaining high standards of quality and safety.

In conclusion, 7018 welding electrode factories serve as the backbone of the welding industry, producing electrodes that are essential for achieving strong, reliable, and safe welds. Their commitment to quality control, safety, and sustainability not only enhances the effectiveness of welding practices but also promotes a responsible approach to manufacturing. As industries continue to grow and evolve, the role of these factories in providing high-quality welding electrodes will remain increasingly significant, making them integral to the future of modern manufacturing.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025