China ER70S-G Welding Wire Supplier for High-Quality Welding Solutions and Services

The Role of China ER70S-G Welding Wire Suppliers in the Global Market

Welding, a crucial process in metal fabrication, repair, and construction, relies on high-quality materials to ensure strong and durable joints between components. Among the various types of welding wires, ER70S-G is widely recognized for its superior performance in both carbon dioxide (CO2) and gas metal arc welding (GMAW) applications. As the demand for quality welding supplies continues to rise, China has emerged as a leading supplier of ER70S-G welding wire, playing a significant role in the global market. This article explores the relevance of Chinese suppliers in the welding industry, the characteristics of ER70S-G welding wire, and the implications for manufacturers and fabricators worldwide.

Understanding ER70S-G Welding Wire

The ER70S-G welding wire is a carbon steel welding wire that is particularly aimed at various welding applications where high weld quality is imperative. It offers excellent arc stability, low spatter, and good fluidity, making it ideal for a range of welding tasks. The 'ER' in ER70S-G stands for Electrode Rod, and the '70' indicates a minimum tensile strength of 70,000 PSI. The wire's composition typically includes iron, manganese, and silicon, which contribute to its weldability and mechanical properties.

ER70S-G welding wire is commonly used in industries like construction, automotive, and heavy machinery. Its versatility enables it to be utilized effectively with various shielding gases, including carbon dioxide and argon mixtures. This adaptability makes it a preferred choice for many welders who prioritize efficiency and performance in their projects.

China's Dominance in the Welding Wire Market

China's emergence as a powerhouse in the manufacturing of welding supplies, including ER70S-G welding wire, can be attributed to several factors. Firstly, the country's robust industrial base and investment in modern manufacturing technologies have allowed for the production of high-quality welding materials at competitive prices. Chinese suppliers leverage economies of scale, producing large volumes that can meet the rising demands of both domestic and international markets.

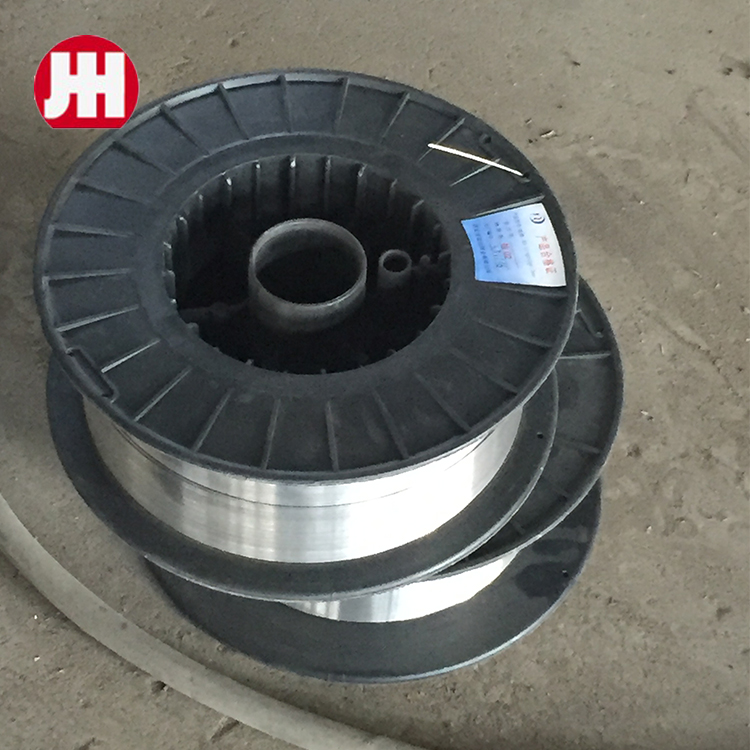

china er70s-g welding wire supplier

Secondly, the stringent quality control measures adopted by Chinese manufacturers ensure that their products meet international standards. Many suppliers have obtained certifications such as ISO 9001, which bolsters buyer confidence in the quality and reliability of their welding wires. This adherence to quality standards is critical, especially when dealing with safety-sensitive industries like construction and aerospace.

Moreover, China's strategic location within Asia enables efficient logistics and distribution networks. Suppliers can quickly respond to customer orders and facilitate prompt deliveries to various parts of the world. This logistical advantage enhances China's appeal as a go-to source for welding supplies, including ER70S-G welding wire.

Implications for Global Manufacturers and Fabricators

For manufacturers and fabricators around the globe, the availability of high-quality ER70S-G welding wire from Chinese suppliers presents both opportunities and challenges. On one hand, access to affordable, high-performance welding wire can significantly reduce production costs and improve overall productivity. Companies can benefit from cost savings without compromising on the quality of their welds, leading to increased competitiveness in the market.

On the other hand, the influx of Chinese welding wire into global markets raises concerns about the potential for market saturation and the impact on local manufacturers. Companies in countries that rely heavily on domestic production may find it challenging to compete with the pricing and quality offered by Chinese suppliers. As a result, they may need to innovate or specialize in niche markets to maintain their market share.

Conclusion

In conclusion, Chinese suppliers of ER70S-G welding wire have established themselves as major players in the global welding market. Their ability to produce high-quality materials at competitive prices, backed by efficient logistics and stringent quality control, positions them favorably in the industry. For manufacturers and fabricators worldwide, collaborating with reliable Chinese welding wire suppliers can lead to improved efficiency and cost-effectiveness. However, it also necessitates strategic planning to navigate the competitive landscape and leverage the advantages that these suppliers offer. As the welding industry continues to evolve, the contributions of Chinese ER70S-G welding wire suppliers will undoubtedly shape its future trajectory.

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025