electrodes welding manufacturer

The Importance of Electrode Welding Manufacturers in Modern Manufacturing

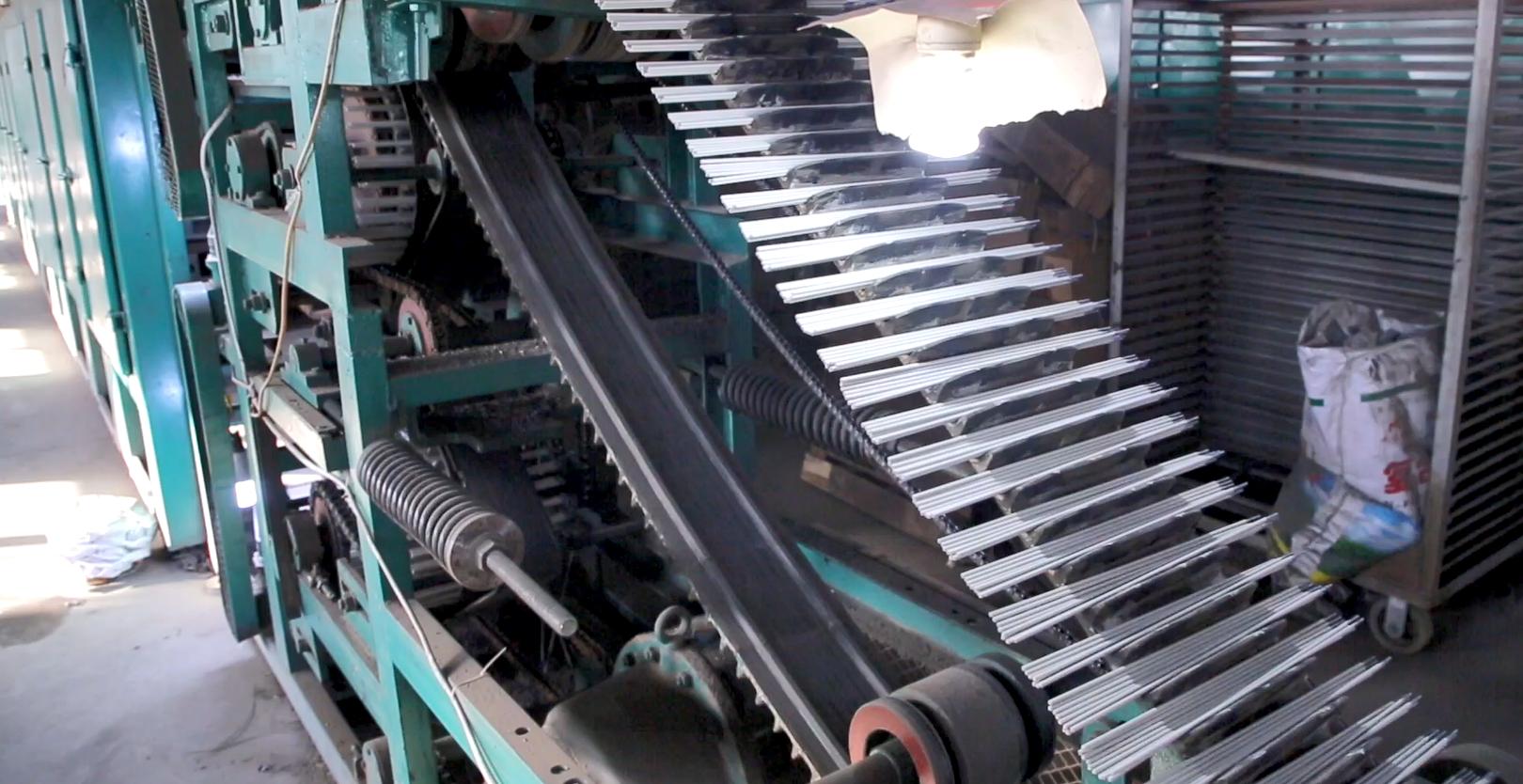

In the arena of manufacturing and construction, welding plays a pivotal role in assembling metal structures, components, and systems. Among the various types of welding methods, electrode welding stands out for its versatility and efficiency. At the heart of this process are electrode welding manufacturers, whose products and innovations significantly impact the quality, safety, and effectiveness of welding operations.

Electrode welding typically involves the use of an electrode to produce heat through an electric current, enabling the bonding of materials. This method is commonly utilized in arc welding and is favored for its ability to join various types of metals effectively. Electrode welding manufacturers supply a range of electrodes designed for specific applications, each engineered to offer distinct benefits, such as enhanced strength, corrosion resistance, and improved weld appearance.

The Importance of Electrode Welding Manufacturers in Modern Manufacturing

Safety is another vital aspect where electrode welding manufacturers make a significant contribution. Welding can pose numerous risks, from exposure to harmful fumes to the dangers associated with high temperatures and electrical currents. Many manufacturers prioritize safety by producing electrodes that minimize hazardous emissions and provide greater control during the welding process. Moreover, they often adhere to stringent regulatory standards, ensuring that their products meet safety requirements. This commitment to safety allows companies to protect their workforce while maintaining compliance with industry regulations.

electrodes welding manufacturer

In addition to producing high-quality electrodes, many manufacturers also offer valuable support and training to their clients. Understanding how to select the right electrode for a specific application can be challenging, especially with the myriad of options available on the market. By providing guidance and expertise in electrode selection, manufacturers can help businesses optimize their welding processes. This support extends to training on welding techniques and best practices, empowering operators to utilize electrodes effectively and safely.

Furthermore, the globalization of manufacturing has led to increased competition, pushing electrode welding manufacturers to innovate consistently. Companies are now focusing on producing eco-friendly electrodes that reduce environmental impact. These developments are pivotal as industries strive to adhere to sustainability goals and reduce their carbon footprints. By investing in greener production methods and materials, manufacturers not only meet regulatory requirements but also attract environmentally conscious clients.

Lastly, the evolving landscape of technology in manufacturing also influences electrode welding. The integration of automation, robotics, and advanced digital monitoring systems has transformed welding operations. Manufacturers are adapting to these changes by developing electrodes compatible with automated welding systems, ensuring seamless integration that enhances productivity and precision.

In conclusion, electrode welding manufacturers play an indispensable role in the welding industry. Their commitment to quality, safety, innovation, and customer support positions them as key players in modern manufacturing. As industries evolve and new challenges emerge, these manufacturers will continue to be at the forefront, driving advancements that improve welding processes and contribute to the overall efficiency and safety of metal fabrication.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025