metal cored welding wire manufacturers

The Rise of Metal-Cored Welding Wire Manufacturers

In the welding industry, the choice of welding wire significantly impacts the quality and efficiency of operations. Among various options available, metal-cored welding wires have gained prominence for their exceptional performance and versatility. This article explores the emergence of metal-cored welding wire manufacturers and their contribution to meeting the evolving demands of the welding sector.

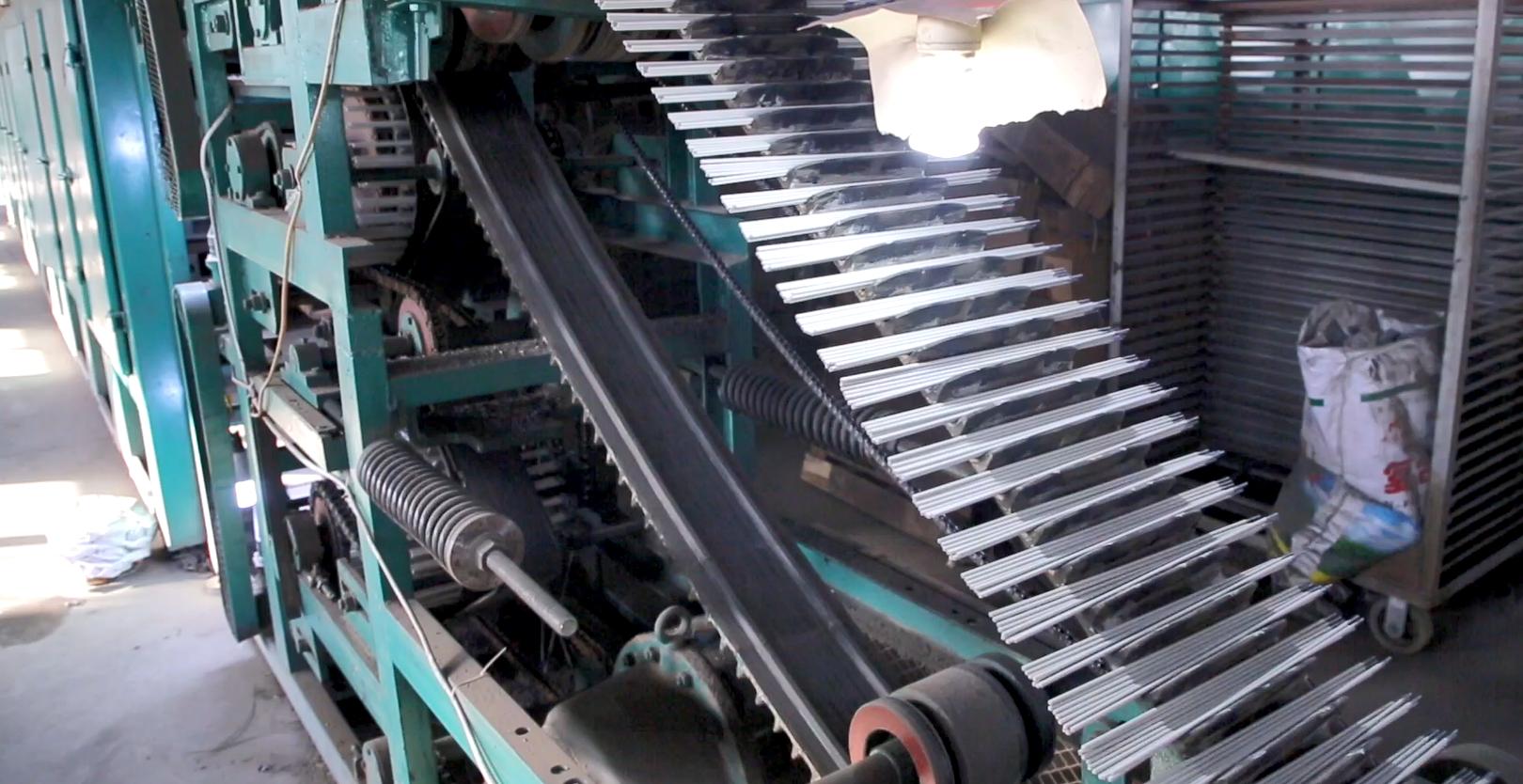

Metal-cored welding wires combine the best features of solid and flux-cored wires. They consist of a hollow wire filled with metal powder that enhances welding properties. This design allows for higher deposition rates and improved arc stability, making metal-cored wires ideal for applications requiring high productivity. Manufacturers have recognized this potential and are increasingly focusing on developing advanced formulations to cater to various welding applications, including structural steel fabrication, shipbuilding, and industrial maintenance.

One of the key reasons behind the growth of metal-cored welding wire manufacturers is the demand for increased efficiency in industrial operations. Companies are constantly seeking methods to enhance productivity while maintaining the highest quality standards. Metal-cored wires enable welders to achieve faster travel speeds and deeper penetration, reducing the time and resources needed for each project. As a result, manufacturers are investing in research and development to enhance the performance of these wires, exploring new alloy compositions and processing methods.

metal cored welding wire manufacturers

In addition to performance benefits, metal-cored welding wires offer advantages in terms of spatter reduction and overall weld appearance. A smoother weld surface often translates to less post-weld cleanup, which is a significant advantage for fabricators. Manufacturers are responding to these needs by providing comprehensive product lines that cater to various material types and thicknesses, ensuring that welders can find the right solution for their specific applications.

The competitive landscape of metal-cored welding wire manufacturing is also evolving. As more players enter the market, companies are focusing on sustainability and environmental responsibility. They are developing welding wires that minimize harmful emissions and are easier to recycle, aligning with global efforts to reduce industrial footprints.

In conclusion, the surge in metal-cored welding wire manufacturers reflects the industry's ongoing quest for efficiency, quality, and sustainability. As technology advances and new materials are developed, the future looks promising for this segment of the welding industry. Welders can look forward to more innovative solutions that will enhance their capabilities and streamline their processes, ultimately leading to superior products and services in the marketplace.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025