stainless welding wire 0.8mm supplier

The Importance of Selecting the Right Stainless Steel Welding Wire A Focus on 0.8mm Suppliers

When it comes to welding processes, the choice of materials is crucial to achieving high-quality results. One of the most critical components in welding is the filler material used, and stainless steel welding wire is among the most popular options for various applications. In recent years, the demand for specific sizes, such as 0.8mm stainless steel welding wire, has increased, prompting suppliers to innovate and cater to this market. This article explores the significance of selecting the right supplier for 0.8mm stainless steel welding wire and what factors to consider.

Understanding Stainless Steel Welding Wire

Stainless steel welding wire is employed in various welding techniques, including Metal Inert Gas (MIG) welding and Tungsten Inert Gas (TIG) welding. Its resistance to corrosion, high temperatures, and mechanical stresses makes it an ideal choice for various industries, including construction, automotive, and food processing. The diameter of the welding wire plays a vital role in determining the welding process's effectiveness, and the 0.8mm size is particularly favored in applications requiring precision and control.

The Rise of 0.8mm Stainless Steel Welding Wire

The 0.8mm stainless steel welding wire is preferred for processes involving thin materials, where precision is key. This size allows for better control during welding, especially in tight spaces or delicate components. Manufacturers and fabricators increasingly select 0.8mm welding wire for its ability to facilitate clean welds with less spatter, which translates into minimal post-weld cleaning.

With the surge in applications requiring fine welding, suppliers are stepping up to meet the growing demand for high-quality 0.8mm stainless steel welding wire. However, not all suppliers are created equal, and the choice of supplier can significantly impact the quality of the welding project.

Key Factors to Consider When Choosing a Supplier

stainless welding wire 0.8mm supplier

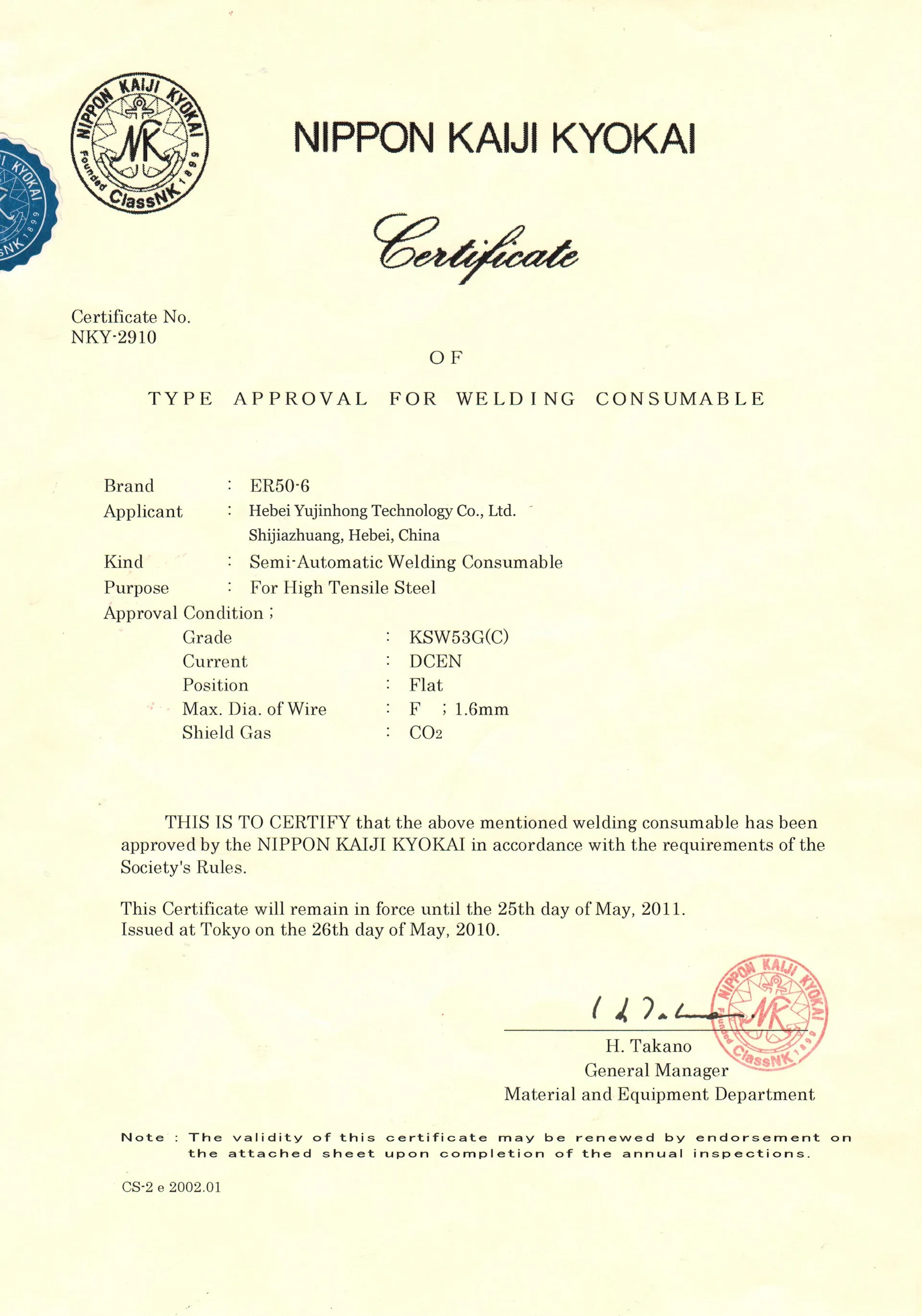

1. Quality Assurance First and foremost, the supplier’s commitment to quality must be assessed. Look for suppliers that adhere to international standards such as ISO 9001. A reliable supplier will provide certifications and test results to ensure their products meet the required specifications.

2. Product Range While focusing on 0.8mm stainless steel welding wire, it’s beneficial to choose suppliers that offer a range of options within that specification, including different alloy compositions (e.g., 308L, 316L) and coatings. This flexibility allows welders to select the best wire for their specific applications.

3. Customer Support and Service Excellent customer service is vital in the manufacturing industry. A good supplier should be willing to provide technical support, product recommendations, and guidance on usage to ensure that customers can maximize their welding processes.

4. Pricing and Availability While pricing shouldn’t be the only criterion, it’s essential to compare costs among various suppliers to ensure competitive pricing without compromising quality. Additionally, consider the supplier's ability to fulfill orders promptly, as delays can impact project timelines.

5. Reviews and Reputation The reputation of a supplier can often be gauged through customer reviews and testimonials. Engaging with other professionals in the industry and seeking recommendations can provide insights into reliable suppliers.

Conclusion

Choosing the right supplier for 0.8mm stainless steel welding wire is a critical decision that can significantly influence the quality and efficiency of welding projects. As industries continue to evolve, the demand for specialized welding wire will only grow, making it essential to partner with suppliers who are committed to quality, support, and innovation. By considering factors such as quality assurance, product range, customer service, pricing, and reputation, businesses can ensure they are well-equipped to meet the challenges of today’s manufacturing landscape. Ultimately, investing time in selecting the right supplier will lead to enhanced productivity and superior welding results.

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025