wholesale mig welder wire manufacturers

The Rise of Wholesale MIG Welder Wire Manufacturers

In the world of welding, the quality of the materials used is crucial for achieving strong, reliable joints in metal fabrication. One of the key components in this process is MIG (Metal Inert Gas) welder wire. As the welding industry evolves, there has been a significant rise in the demand for wholesale MIG welder wire manufacturers, driven by various factors including cost efficiency, quality control, and the growing application of welding technology across diverse industries.

Understanding MIG Welding and Its Components

MIG welding is a popular welding process that utilizes a continuous solid wire electrode, which is fed through a welding gun. This wire is melted down to form a weld pool that joins two pieces of metal together. The process also requires a shielding gas, typically argon, to protect the weld from contamination by the environment. The choice of welding wire is critical, as it directly influences the strength and appearance of the weld.

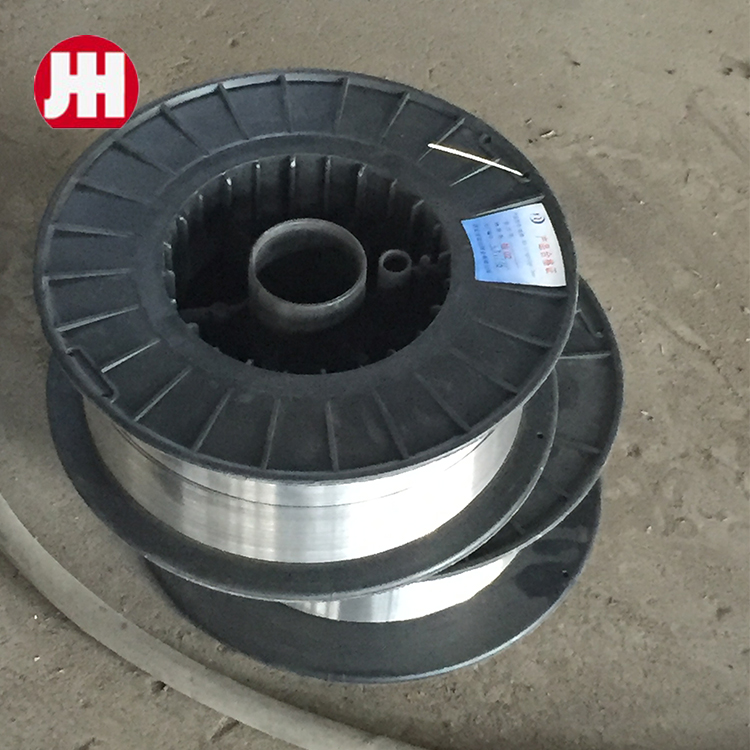

Various types of MIG welding wire are available, including solid wire, flux-cored wire, and metal-cored wire. Each type serves a specific purpose and is suited for different applications. Wholesale manufacturers produce these wires in bulk, making them readily available for businesses ranging from small workshops to large fabrication shops.

The Benefits of Buying from Wholesale Manufacturers

1. Cost-Effectiveness One of the primary advantages of purchasing MIG welder wire from wholesale manufacturers is the cost savings. By buying in bulk, companies can significantly reduce their material costs, allowing them to allocate resources to other critical areas of their business.

2. Consistent Quality Established wholesale manufacturers often adhere to stringent quality control measures. This ensures that the welding wire produced meets high industry standards, providing users with confidence in the reliability of their materials. Consistency in quality is vital, especially for businesses involved in high-stakes projects where safety and durability are paramount.

wholesale mig welder wire manufacturers

3. Customization Options Many wholesale manufacturers offer customization options, allowing businesses to specify the type of wire or the diameter that fits their particular needs. This flexibility helps ensure that customers receive products tailored to their specific applications, enhancing overall efficiency in their welding processes.

4. Accessibility and Variety The growing number of wholesale manufacturers has led to increased accessibility of various types of MIG welder wire. Businesses now have more options to choose from, whether they require specific alloy compositions or different spool sizes, thus finding the perfect fit for their projects.

The Impact of Technological Advancements

In recent years, technological advancements have revolutionized the welding industry, including improvements in the production processes of welding wire. Automation and precision manufacturing techniques have enabled wholesale manufacturers to produce high-quality MIG welding wire at a faster rate and with less waste. These advancements not only improve efficiency but also contribute to sustainability efforts within the industry.

Moreover, with the emergence of online platforms, the procurement of MIG welder wire has become easier than ever. Customers can compare prices, read reviews, and order products from the comfort of their workplaces, turning the purchasing process into a seamless experience.

Conclusion

The rise of wholesale MIG welder wire manufacturers is a reflection of the dynamic needs of the welding industry. As more businesses recognize the benefits of sourcing their welding materials from bulk suppliers, the emphasis on quality, cost efficiency, and customization will continue to drive growth in this sector. As technology evolves, so will the manufacturing processes, further enhancing the quality and availability of MIG welder wire. For both small and large enterprises, establishing partnerships with wholesale manufacturers can lead to improved welding outcomes and long-term success in their fabrication endeavors.

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025