Wholesale 1.2mm Tubular Welding Wire for Quality Fabrication and Efficient Welding Solutions

Understanding Wholesale Tubular Welding Wire (1.2mm) A Comprehensive Guide

In the ever-evolving world of manufacturing and construction, welding remains a cornerstone technique that ensures the integrity of structures and machinery alike. One of the most popular forms of welding wire today is the tubular welding wire, particularly the 1.2mm size, which has garnered considerable attention in wholesale markets. This article will delve into the world of wholesale tubular welding wire, exploring its features, applications, benefits, and why it has become a preferred choice for many professionals.

What is Tubular Welding Wire?

Tubular welding wire is a type of filler material that consists of a hollow tubular structure filled with flux. The flux serves several critical purposes, including shielding the weld pool from atmospheric contamination and providing additional alloying elements to enhance the overall quality of the weld. The 1.2mm diameter is especially popular due to its versatility and ease of use in various welding applications.

Advantages of 1.2mm Tubular Welding Wire

1. Enhanced Weld Quality The unique characteristics of tubular welding wire allow for superior arc stability and a smoother weld pool, leading to stronger and clearer welds. This results in reduced spatter and less rework, which is essential in high-quality manufacturing processes.

2. Higher Deposition Rates The tubular design enables greater deposition rates when compared to solid wires. This translates to increased productivity, as welders can complete projects more quickly without sacrificing quality.

3. Versatility The 1.2mm diameter makes this type of welding wire suitable for various materials, including mild steel, stainless steel, and some nickel alloys. This adaptability is particularly beneficial for industries that require different materials for different applications.

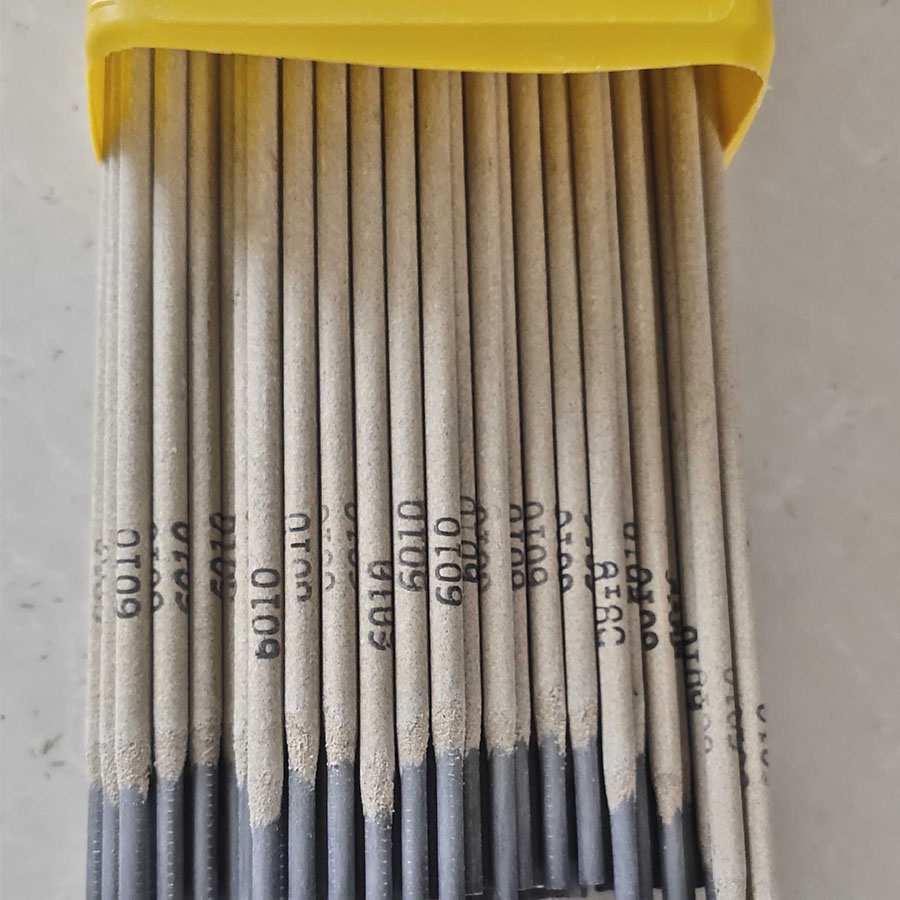

wholesale tubular welding wire 1.2mm

4. Reduced Welding Fume Generation Welders are increasingly concerned about health and safety, and tubular welding wires typically produce less fume compared to other types. This is due to the efficient burning of the flux, which lowers the amount of harmful byproducts released into the atmosphere.

Applications

Tubular welding wire (1.2mm) finds applications in numerous industries, including

- Manufacturing Ideal for constructing heavy machinery and structural components. - Shipbuilding Used in the fabrication of ships and marine vessels that require robust welds. - Automotive Industry Essential in manufacturing automotive frames and components that must withstand high stress. - Pipeline Construction Perfect for creating strong and reliable welds in pipeline systems that transport gas, oil, and other fluids.

The Wholesale Market

The demand for 1.2mm tubular welding wire has led to a burgeoning wholesale market. Suppliers offer competitive pricing and bulk purchasing options, making it accessible for both small workshops and large industrial manufacturers. Purchasing in wholesale allows businesses to stock their supplies efficiently while also benefitting from cost savings associated with larger orders.

Conclusion

In conclusion, wholesale tubular welding wire in 1.2mm diameter is an exceptional choice for professionals in various industries. Its unique features, such as enhanced weld quality, increased deposition rates, versatility, and reduced fume generation make it a preferred option for many applications. As manufacturing processes continue to evolve, the importance of high-quality materials like tubular welding wire cannot be overstated. For businesses looking to improve their welding operations, investing in quality tubular welding wire could be the key to achieving better performance and efficiency. Whether you're in manufacturing, shipbuilding, automotive, or pipeline construction, incorporating 1.2mm tubular welding wire into your workflow is sure to yield positive results.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025