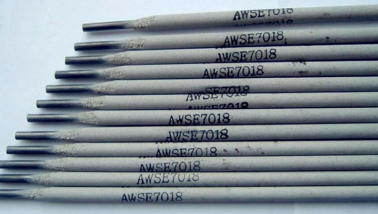

3 32 welding rod 7018 factory

Understanding the 3% 2032 Welding Rod 7018 A Overview of a Reliable Manufacturing Choice

Welding is a vital process in various industries, from construction to automotive. The choice of welding rod can significantly affect the quality and integrity of the weld. Among the many options available, the 3% 2032 welding rod 7018 has emerged as a reliable choice for both professional welders and industrial manufacturers. In this article, we will explore the characteristics, applications, and advantages of this particular welding rod.

What is the 3% 2032 Welding Rod 7018?

The 7018 welding rod is a type of low-hydrogen electrode that is primarily used for welding mild and low-alloy steels. The 70 in its classification indicates that it can yield a minimum tensile strength of 70,000 psi. The 1 in 7018 denotes that it is suitable for all-position welding, while the 8 signifies that it is designed for use with DC current. The addition of 3% in its name suggests a specific formulation that is geared towards enhancing certain properties, possibly related to its alloying elements or coating composition.

Unique Features and Benefits

One of the standout features of the 3% 2032 welding rod 7018 is its low-hydrogen content. This property reduces the risk of hydrogen-induced cracking, especially when welding high-strength steels. The rod produces a smooth arc, allowing for better penetration and a clean weld bead. Its excellent mechanical properties make it particularly suitable for critical applications where weld integrity is paramount.

The coatings on the 7018 rods help stabilize the arc and provide a protective gas shield that minimizes oxidation during the welding process. This ensures a high-quality finish and improved corrosion resistance. Moreover, the rods are designed to produce less spatter, which simplifies cleanup and reduces the need for post-weld treatment.

3 32 welding rod 7018 factory

Applications in Various Industries

The 3% 2032 welding rod 7018 is utilized across multiple sectors. In construction, it is widely used for steel structures, bridges, and pipelines, where strength and reliability are crucial. The automotive industry also employs this type of welding rod for assembling components that require precision and durability. Additionally, fabricators and repair shops often opt for 7018 rods due to their versatility and the high level of quality they bring to welds.

Factory Production and Quality Control

Manufacturing 3% 2032 welding rods involves rigorous quality control processes to ensure consistency and performance. Factories specializing in welding rod production typically utilize advanced machinery and techniques to regulate the alloy composition and coating thickness. These facilities often conduct regular testing to confirm that the rods meet industry standards and client specifications.

With growing environmental and safety concerns, leading manufacturers are also adopting eco-friendly practices in their production processes. This includes using sustainable materials and reducing waste, ensuring that their operations are not only profitable but also responsible.

Conclusion

The 3% 2032 welding rod 7018 continues to be a cornerstone in the welding industry, combining strength, versatility, and reliability. Its specific formulation helps achieve superior weld quality, making it a preferred choice among professionals. As industries strive to enhance their welding processes and outcomes, the 7018 welding rod remains an essential tool for achieving durable and high-performance welds. With ongoing advancements in manufacturing techniques and materials, the future of welding will likely see further innovations in rods such as the 3% 2032, enhancing both safety and efficiency in welding applications.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025