Welding Rod Production Trends and Insights from the 2010 Industry Landscape

The Welding Rod Industry A 60% Market Share Insight (2010)

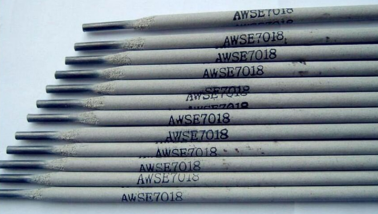

Welding is a vital industrial process utilized in a variety of sectors, including construction, manufacturing, automotive, and aerospace. At the heart of this process lies the welding rod, a consumable that plays a crucial role in ensuring strong, durable welds. As of 2010, the welding rod market was characterized by extensive competition, evolving technology, and a significant concentration of market share among a few key players.

Understanding the Market Dynamics

The global demand for welding rods is largely driven by the recovery of the construction and manufacturing sectors, especially following the economic downturn in 2008. Government investments in infrastructure, housing, and industrial projects fueled this demand, creating a substantial market for welding-related products. By 2010, it was estimated that the market was dominated by around 60% of major welding rod manufacturers, indicating a concentrated industry structure where large companies played a pivotal role in shaping market trends.

The Key Players and Their Strategies

Several companies emerged as prominent players within this 60% market share. These manufacturers focused on innovation and technological advancements to improve their product offerings. For instance, they invested heavily in research and development to create welding rods that not only meet stringent industry standards but also cater to specific customer requirements. This approach enabled them to offer a wide variety of products, including coated rods, solid wire, and flux-cored wires, tailored for different applications.

Additionally, these manufacturers implemented comprehensive marketing strategies to establish strong brand identities. By emphasizing quality, performance, and reliability, they built customer loyalty and expanded their market reach. Some companies also initiated partnerships with equipment manufacturers to provide comprehensive welding solutions, further solidifying their market position.

Regional Market Insights

Geographically, the welding rod market showcased diverse dynamics. North America and Europe were significant markets due to the presence of established construction and manufacturing industries. In these regions, high safety and quality standards necessitated the use of superior welding rods, thus benefiting manufacturers with advanced technologies. On the other hand, emerging markets in Asia, particularly China and India, were witnessing rapid industrial growth. This growth provided an opportunity for welding rod manufacturers to penetrate these markets, offering products at competitive prices while gradually increasing their presence.

60 10 welding rod manufacturer

Technological Advancements and Innovation

Innovation remains a cornerstone of the welding rod industry. In 2010, advancements in welding technologies, including automated welding systems and enhanced welding processes, significantly influenced the types of welding rods produced. Manufacturers focused on developing rods that could withstand higher temperatures and provide better arc stability. These innovations not only improved the efficiency of the welding process but also reduced welding costs, making it attractive for industries aiming to enhance productivity.

The introduction of environmentally friendly welding rods also emerged as a trend in 2010. As industries began to emphasize sustainability, manufacturers responded by creating products with lower emissions and less environmental impact during the welding process. This shift not only catered to the growing demand for green technologies but also positioned these manufacturers as leaders in corporate social responsibility within the industry.

Challenges Facing the Industry

Despite the promising growth and consolidation of the welding rod market, several challenges persisted in 2010. Fluctuations in raw material prices, particularly for materials like steel and alloys, posed significant threats, impacting production costs. Additionally, manufacturers faced pressure to comply with increasingly stringent regulations regarding product safety and environmental standards. Therefore, staying ahead of compliance while maintaining profitability became crucial for industry players.

Moreover, the competition was intensifying, with smaller manufacturers trying to capture market share through price competition and niche products. This competitive landscape required established players to continuously innovate and improve their operational efficiencies to maintain their leading positions.

Conclusion

The welding rod manufacturing industry in 2010 was marked by a 60% market share concentration among key manufacturers who leveraged innovation and strategic partnerships to establish dominance. With ongoing technological advancements and a focus on sustainability, these players were well-positioned to navigate the challenges ahead. As industries continued to evolve, the demand for high-quality welding rods would remain critical, solidifying their importance in a wide range of applications and driving the industry's growth into the future.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025