china electrodos e-7018

Understanding the E-7018 Electrode A Key Component in Welding

Welding is an essential manufacturing process used globally to join materials, particularly metals. Among the various welding electrodes available, the E-7018 electrode stands out due to its versatility and high performance. This article will explore the features, applications, and significance of the E-7018 electrode, particularly in the context of Chinese production and innovation.

What is the E-7018 Electrode?

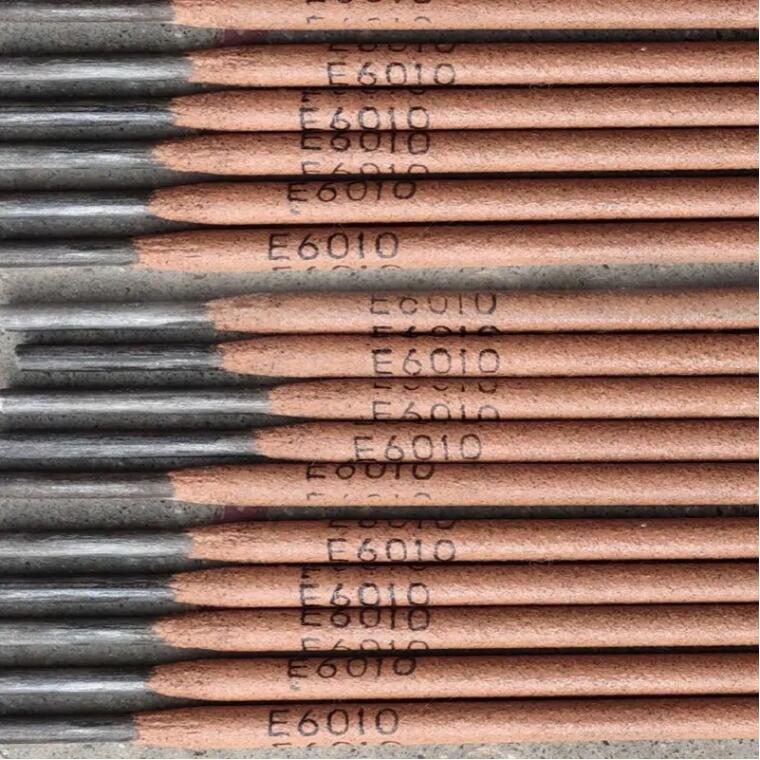

The E-7018 electrode is a type of low hydrogen welding rod commonly used in arc welding processes. The “E” stands for electrode, while “70” indicates a minimum tensile strength of 70,000 psi. The “1” denotes that it can be used in all positions (flat, horizontal, vertical, and overhead), and “8” indicates the type of coating and the welding current it requires—direct current (DC) or alternating current (AC) for versatility in different welding operations.

One of the primary features of the E-7018 electrode is its low hydrogen content, which reduces the risk of hydrogen-induced cracking in the weld joint. This quality makes it particularly suitable for critical applications where joint integrity is paramount.

Manufacturing and Quality in China

China has emerged as a significant producer of welding electrodes, including the E-7018. The country's robust manufacturing capabilities, combined with advancements in technology, have positioned it as a key player in the global welding supplies market. Chinese manufacturers invest heavily in research and development to enhance the quality and performance of their electrodes.

Many Chinese E-7018 electrodes undergo strict quality control measures to meet international standards. They are subjected to rigorous testing for tensile strength, ductility, and impact resistance. This emphasis on quality ensures that the E-7018 electrodes can withstand demanding environments, making them a preferred choice for various applications.

Applications of E-7018 Electrodes

E-7018 electrodes find a wide range of applications across industries. They are prevalent in shipbuilding, construction, and manufacturing, where strong and durable welds are required. For instance, in construction, E-7018 electrodes are frequently used in the fabrication of steel structures, bridges, and buildings. Their ability to produce clean and strong welds helps ensure structural integrity.

china electrodos e-7018

In the pipeline industry, E-7018 electrodes are often employed for welding high-strength steels and low-alloy steels. Given the extreme conditions that pipelines may encounter, including pressure variations and environmental factors, using a high-quality electrode like E-7018 is essential.

Moreover, the versatility of E-7018 electrodes makes them ideal for maintenance and repair operations, allowing welders to perform repairs on machinery and infrastructure effectively.

Benefits of Using E-7018 Electrodes

There are several benefits to using E-7018 electrodes in welding applications

1. Reduced Risk of Cracking The low hydrogen content significantly decreases the chances of cracking in the welded joint, making them suitable for critical applications.

2. All-Position Use The ability to weld in all positions increases versatility, enabling welders to work in various orientations without compromising weld quality.

3. Strong Welds E-7018 electrodes provide excellent tensile strength, resulting in durable and reliable welds that can withstand harsh conditions.

4. Weld Appearance The coating burns consistently and provides a smooth, aesthetically pleasing finish to the weld bead.

Conclusion

The E-7018 electrode is a crucial component in the welding industry, offering durability, strength, and versatility across multiple applications. China's advancements in manufacturing and commitment to quality have made its E-7018 electrodes some of the most sought-after in the global market. As industries continue to evolve and demand stronger and more reliable welding solutions, the relevance of the E-7018 electrode remains significant, ensuring its place as a preferred choice for welders worldwide. As we look to the future, continuous improvements in electrode technology will only enhance the capabilities and applications of the E-7018, further cementing its status as a critical tool for industrial progress.

-

Welding Rod for Manganese Steel High-Strength & Crack-ResistantNewsJun.01,2025

-

High-Strength 7024 Welding Rods Wholesale Supplier in ChinaNewsJun.01,2025

-

ER 309L Electrode - High Corrosion Resistant Welding Rods China SuppliersNewsJun.01,2025

-

SG2 TIG Welding Wire Rod 2.4mm Durable & Wholesale Supplier ChinaNewsMay.31,2025

-

Premium 3.2mm 7018 Welding Electrodes Durable & High-Strength RodsNewsMay.31,2025

-

AC Stainless Steel Welding Rods High-Performance & Corrosion-ResistantNewsMay.31,2025