Top Manufacturers of Flux Core MIG Wire in China

The Rise of China’s Flux Core MIG Wire Factories

In recent years, China has emerged as a global leader in the production of welding materials, with flux core MIG (Metal Inert Gas) wires being a significant segment of the market. As the demand for effective and versatile welding products increases, the factories dedicated to producing flux core MIG wires in China have ramped up their operations, showcasing advanced technology and production capabilities.

Flux core MIG welding is a process that employs a tubular wire filled with flux at its core. This type of welding is particularly advantageous for its ability to function effectively in outdoor environments and windy conditions, making it a preferred choice in various industrial applications. The popularity of this technology has spurred numerous factories in China to specialize in the manufacturing of flux core MIG wires, catering to both domestic and international markets.

The Rise of China’s Flux Core MIG Wire Factories

The Chinese production network also benefits from a robust supply chain, making it easier for factories to source raw materials economically. This includes the procurement of steel and other metals that are essential for making flux core MIG wires. The relatively low cost of labor in China further contributes to competitive pricing, allowing manufacturers to offer quality products at lower prices than many of their international counterparts.

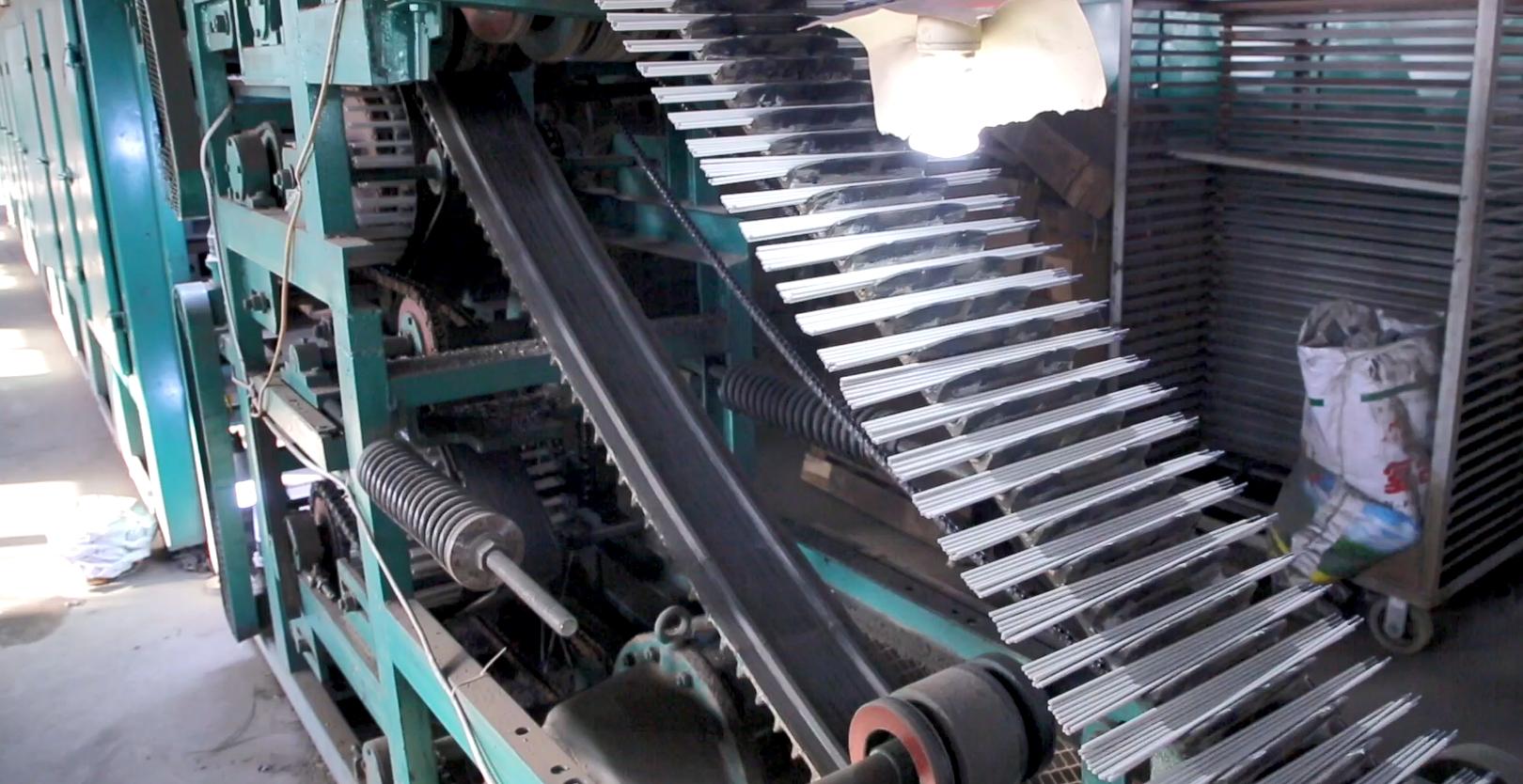

china flux core mig wire factories

As the global landscape of manufacturing and supply chains evolves, the Chinese factories continue to adapt to changing demands from different industries. There has been a noticeable trend towards customization, with factories being able to produce specialized flux core MIG wires tailored for specific applications, such as shipbuilding, construction, and automotive industries. This flexibility has made Chinese manufacturers a preferred partner for businesses around the world.

In parallel with growth comes responsibility, and many factories are now focusing on sustainable production practices. There is an increasing awareness of the environmental impact associated with welding materials, leading manufacturers to invest in greener technologies. This includes using recycled metals and implementing energy-efficient production processes, helping to reduce the overall carbon footprint of flux core MIG wire production.

Moreover, the global demand for skilled labor in the manufacturing sector has prompted many Chinese factories to offer training programs for their workers. This investment in human resources not only enhances productivity but also improves the quality of the products manufactured. Workers are now better equipped with the knowledge and skills required to operate sophisticated machinery, contributing to the overall reputation of Chinese manufacturing on the international stage.

In conclusion, China’s flux core MIG wire factories are at the forefront of the welding materials industry, characterized by advanced technology, competitive pricing, and a strong emphasis on quality and sustainability. As these factories continue to innovate and expand their capabilities, they will likely play an essential role in meeting the world’s ever-growing demand for reliable and high-performance welding solutions. The evolution of this industry in China not only highlights the country’s manufacturing prowess but also its commitment to adapting to the needs of a changing global market.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025