Leading Manufacturer of Gasless Aluminum MIG Welding Wire in China

The Rise of Gasless Aluminum MIG Wire Manufacturing in China

In recent years, China has emerged as a leading manufacturer of various welding materials, including gasless aluminum MIG wire. This development is rooted in the need for efficient, high-quality welding solutions across multiple industries, particularly in automotive, aerospace, and construction. As the demand for lightweight materials continues to grow, aluminum has gained significant popularity, hence the increasing interest in aluminum MIG wires.

Understanding MIG Welding

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding process that employs a continuous solid wire electrode to join materials. Traditionally, MIG welding requires the use of a shielding gas to protect the molten weld pool from atmospheric contamination. However, gasless or self-shielded MIG wires operate without the need for external gas, making them a convenient and cost-effective option, especially for outdoor applications or in windy conditions.

Advantages of Gasless Aluminum MIG Wire

Gasless aluminum MIG wires offer several distinct advantages. First and foremost, they eliminate the need for additional gas, which simplifies the setup and reduces costs. Additionally, self-shielding wires allow for greater flexibility when welding in various environments and conditions. This is particularly pertinent in areas where transporting gas cylinders can be impractical.

Moreover, gasless aluminum MIG wires are designed to produce a clean, strong weld bead, which is essential for structural integrity in various applications. They are particularly effective when working with thinner aluminum materials, which are widely used in modern manufacturing. The ability to produce high-quality welds without the requirements of gas allows manufacturers to save both time and expenses.

China's Manufacturing Landscape

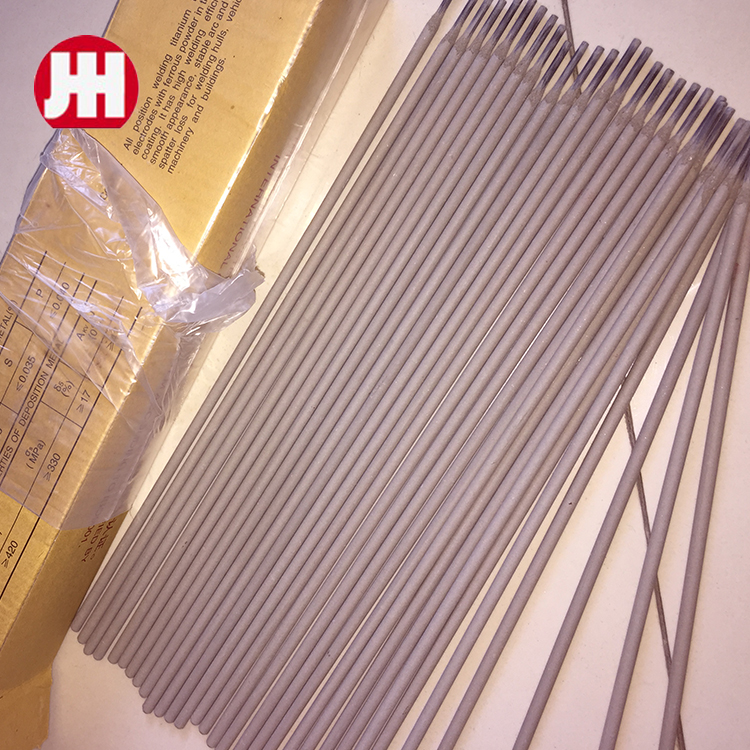

china gasless aluminum mig wire manufacturer

China's status as a powerhouse in the manufacturing sector plays a crucial role in the production of gasless aluminum MIG wire. The country is home to sophisticated manufacturing facilities equipped with advanced technological capabilities. Chinese manufacturers have invested heavily in research and development to enhance the quality and efficiency of their offerings. This commitment to continuous improvement is evident in their competitive production techniques.

Additionally, China benefits from a robust supply chain, allowing for the seamless procurement of raw materials and efficient distribution of finished products. With a workforce skilled in metallurgy and welding technology, China is well-positioned to meet the growing demands of both domestic and international markets.

Meeting Global Demand

The global demand for gasless aluminum MIG wire has soared, driven by various factors, including the automotive industry's shift towards lightweight materials for fuel efficiency, the construction sector's pursuit of durable and resilient structures, and the aerospace industry’s need for reliable materials that can withstand harsh conditions. Chinese manufacturers are leveraging this trend by offering a diverse range of products that cater to specific needs.

Moreover, Chinese firms are increasingly focusing on exporting their products, establishing connections with international distributors and customers. By participating in global trade shows and fostering partnerships abroad, they are expanding their market reach and solidifying their position as key players in the global welding materials industry.

The Future of Gasless Aluminum MIG Wire in China

The future for gasless aluminum MIG wire manufacturing in China looks promising. As industries continue to adopt aluminum for its lightweight and strong properties, the demand for efficient welding solutions will only grow. Moreover, with advancements in manufacturing technologies, including automation and artificial intelligence, Chinese manufacturers will likely improve their production processes, leading to higher quality products and lower costs.

In conclusion, the emergence of gasless aluminum MIG wire manufacturing in China exemplifies the country's ability to innovate and meet the evolving needs of various industries. With ongoing investments in technology and a commitment to quality, Chinese manufacturers are poised to dominate this sector, providing essential solutions for the future of welding and fabrication.

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025