china sg2 tig welding wire rod 2.4mm suppliers

Understanding China SG2 TIG Welding Wire Rod 2.4mm Suppliers

In the realm of welding, the quality of the filler materials used can significantly impact the outcome of the welding process. Among these materials, TIG (Tungsten Inert Gas) welding wire rods have gained substantial popularity due to their versatility and ability to produce high-quality welds. This article examines the significance of SG2 TIG welding wire rods with a diameter of 2.4mm, specifically focusing on suppliers from China.

The Importance of TIG Welding

TIG welding is widely recognized for its precision and control. It uses a non-consumable tungsten electrode to produce the weld, with inert gas shielding that protects the weld pool from contamination. This method is particularly suited for welding thin materials and is often employed in industries ranging from automotive to aerospace, where weld integrity is paramount.

When it comes to filling materials, the type of wire used plays a critical role. The SG2 designation refers to a specific grade of filler wire known for its ability to offer excellent mechanical properties and a smooth weld appearance. In many cases, SG2 welding wire rods are preferred for their compatibility with various materials, including mild steel and low-alloy steel.

Characteristics of 2.4mm SG2 TIG Welding Wire Rods

The 2.4mm diameter is one of the most commonly used sizes in TIG welding. This particular size is particularly favored for its versatility, making it suitable for both thin and thicker workpieces. Here are several key characteristics of 2.4mm SG2 TIG welding wire rods

1. Versatile Application The 2.4mm diameter offers a good balance between ease of handling and welding performance, allowing welders to work on a variety of projects regardless of material thickness.

2. High-Quality Welds SG2 wire is known for producing clean and reliable welds, reducing the chances of defects like porosity or slag inclusion.

3. Good Feedability The 2.4mm size ensures smooth feeding through the welding torch, aiding in maintaining a stable arc and consistent welding speed.

china sg2 tig welding wire rod 2.4mm suppliers

4. Mechanical Strength SG2 welding wire generally displays excellent tensile strength and ductility, making the welded joints robust and capable of withstanding substantial stress.

Supply Chain and Market Dynamics

China has emerged as a significant player in the global welding wire market, primarily due to its advanced manufacturing capabilities and competitive pricing. Many suppliers offer a wide range of welding materials, including SG2 TIG welding wire rods. When choosing a supplier, several factors should be considered

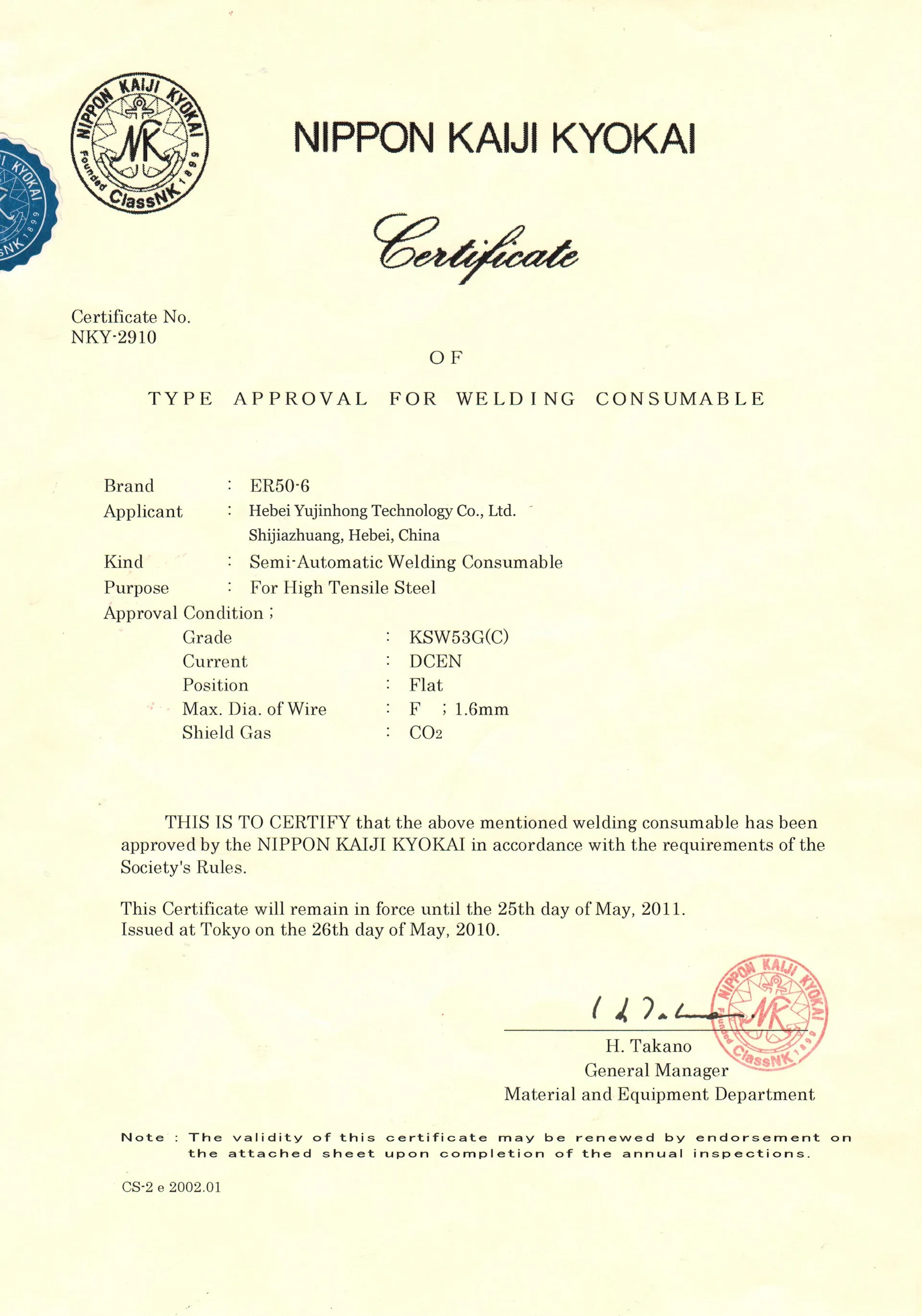

- Quality Assurance Ensure that the supplier adheres to international quality standards, such as ISO certifications, which verify the reliability and safety of their products.

- Product Range A good supplier should provide a variety of welding wires, catering to different applications, including various diameters and alloy compositions.

- Pricing and Terms It is essential to compare pricing among suppliers and consider the terms of purchase, including minimum order quantities and shipping costs. Chinese suppliers often offer competitive rates without compromising quality.

- Customer Service Evaluate the level of customer support offered by the supplier. Prompt response to inquiries, availability of technical support, and after-sales service are crucial for ensuring a smooth purchasing experience.

Conclusion

The market for welding materials, particularly SG2 TIG welding wire rods of 2.4mm diameter, is evolving with increasing demand for quality and performance. Chinese suppliers have positioned themselves as leading entities in this space, providing high-quality products at competitive prices. For welders and industries relying on TIG welding, partnering with reliable suppliers for SG2 welding wire can enhance production efficiency and ensure the integrity of their welded assemblies. Ultimately, selecting the right welding materials is a fundamental step toward achieving successful and lasting welds.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025