china welding electrode 2 5mm manufacturers

The Landscape of China’s 2.5mm Welding Electrode Manufacturers

In the ever-evolving world of welding technologies, the role of welding electrodes, particularly those measuring 2.5mm in diameter, cannot be overlooked. China, being one of the largest manufacturing hubs, produces a significant volume of these essential components, catering to both domestic and international markets. Understanding the dynamics of this industry involves exploring the manufacturing processes, the quality of products, market trends, and the challenges faced by manufacturers.

Manufacturing Processes

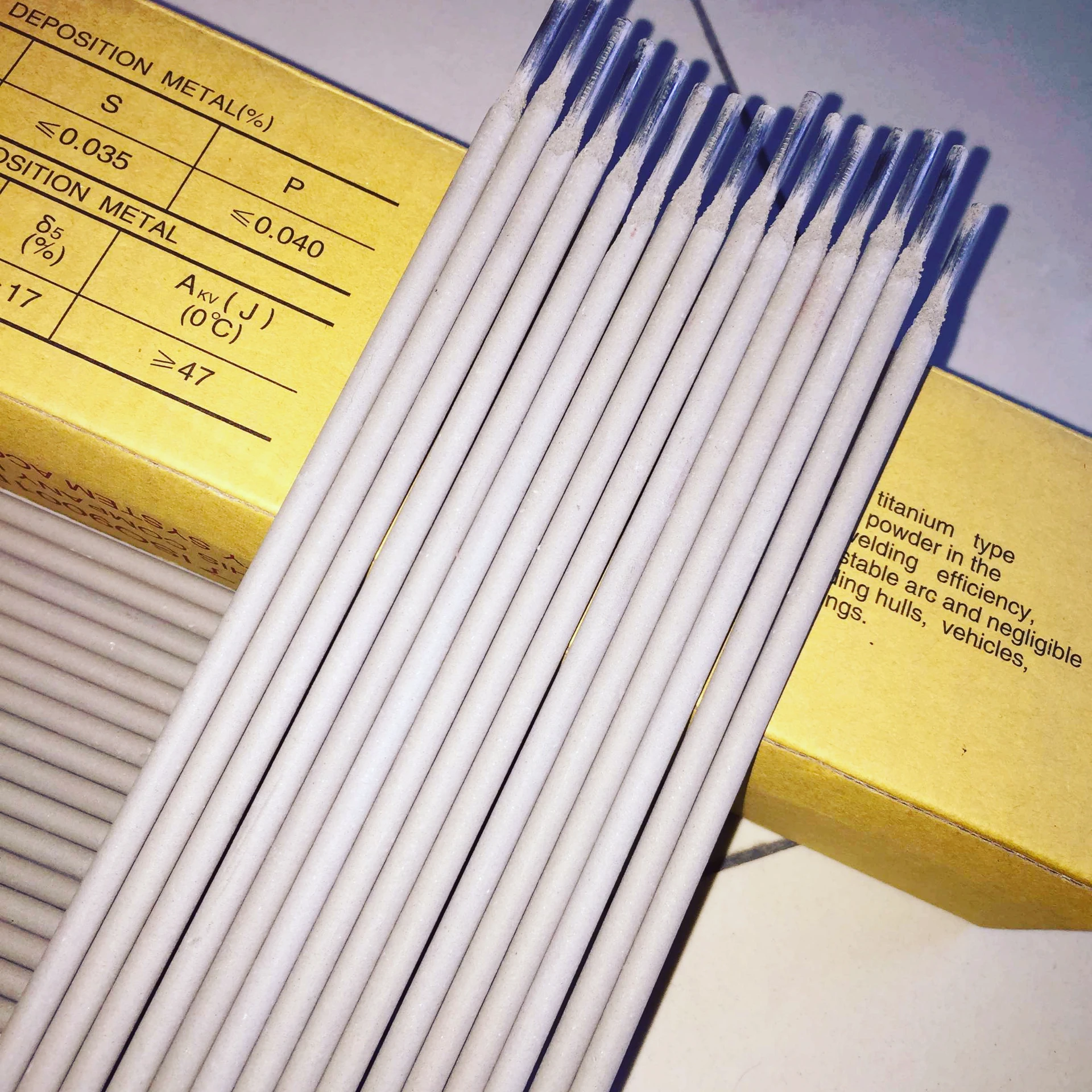

The manufacturing of 2.5mm welding electrodes involves several intricate processes. Typically, raw materials such as steel wires, flux, and various alloying elements are used. The steel wire's quality plays a crucial role in determining the electrode's performance. Once the raw materials are obtained, they are subjected to a series of steps, including drawing, coating, and drying.

The drawing process reduces the diameter of the wire to the desired size, while the coating involves adding a mixture of flux and other materials that enhance the electrode's properties, such as the ease of arc starting and the stability of the arc itself. After coating, the electrodes undergo a drying process to ensure that the flux adheres correctly and is ready for use in various welding applications.

Product Quality and Standards

Quality assurance is paramount in the production of welding electrodes. Chinese manufacturers often adhere to international standards such as ISO and AWS (American Welding Society) to meet global market demands. However, the degree of adherence to these standards can vary significantly among different manufacturers.

Reputable manufacturers invest in advanced technology and skilled labor to ensure their products meet stringent quality requirements. They perform rigorous tests to evaluate the mechanical properties, chemical composition, and performance characteristics of the welding electrodes. This focus on quality not only enhances product reliability but also builds trust with consumers in the global market.

Market Trends and Demands

china welding electrode 2 5mm manufacturers

The demand for 2.5mm welding electrodes is strongly influenced by the construction, automotive, and manufacturing sectors. With China's rapid industrialization and urbanization, these industries have seen a consistent demand for high-quality welding electrodes. Moreover, the growing trend towards automation and advanced manufacturing processes has led to an increase in the use of welding technologies, further driving the demand for specialized electrodes.

In recent years, there has also been a shift towards environmentally friendly welding processes, leading manufacturers to develop electrodes that minimize hazardous emissions. This trend aligns with global sustainability goals and reflects a growing concern for environmental responsibility in industrial practices.

Challenges Faced by Manufacturers

Despite the booming market, manufacturers of 2.5mm welding electrodes in China face several challenges. Competition is fierce, with numerous players in the market offering similar products. This saturation can lead to price wars, which may adversely affect profit margins.

Furthermore, as international standards tighten, manufacturers must continually adapt to new regulations, often requiring significant investment in technology and training. Compliance with environmental regulations also poses a challenge, as manufacturers must balance production costs with sustainable practices.

Another concern is the fluctuation of raw material prices, which can impact production costs and, subsequently, the pricing strategy for welding electrodes. Manufacturers need to develop robust supply chain management strategies to mitigate these risks.

Conclusion

The landscape of 2.5mm welding electrode manufacturers in China is characterized by a mix of opportunities and challenges. As the demand for welding electrodes continues to grow globally, manufacturers must prioritize quality, innovation, and sustainability to thrive in a competitive market. By embracing new technologies and adhering to international standards, China's welding electrode manufacturers can position themselves as leaders in the industry, ensuring they meet both domestic and international demands effectively. As the industry progresses, the evolution of welding technologies will undoubtedly influence the future of manufacturing practices, paving the way for more efficient and environmentally friendly solutions.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025