e6013 welding rods 3.2mm factory

The E6013 Welding Rods Industry Benchmark for Quality and Versatility

Welding is an essential process in various industries, from construction to manufacturing, and the quality of welding rods plays a crucial role in achieving strong, durable, and reliable welds. Among the plethora of welding rods available in the market, the E6013 welding rods, particularly the 3.2mm diameter variant, have carved out a reputation for excellence and versatility. This article delves into the characteristics, applications, and benefits of E6013 welding rods, specifically focusing on their 3.2mm variant and factory manufacturing processes.

Understanding E6013 Welding Rods

The E6013 welding rod is classified under the American Welding Society (AWS) specifications, with the 'E' indicating it is an electrode, '60' denoting the tensile strength (60,000 psi), and '1' suggesting a special characteristic of the weld (in this case, it can be used in all positions). The number '3' points to the type of coating used, which provides a stable arc and smooth finishing. These rods are primarily used for general-purpose welding, making them ideal for a wide range of applications.

Advantages of E6013 Welding Rods

1. Versatility One of the most significant advantages of E6013 welding rods is their versatility. They can be used on various metal types, including mild steel, low alloy steel, and can even cater to thin materials. This characteristic makes E6013 the go-to choice for many fabricators and hobbyists alike.

2. Ease of Use E6013 rods are easy to use, making them suitable for both novice and experienced welders. The stability of the arc and minimal spatter produced during the welding process allow for cleaner finishes and less time spent on post-welding cleanup.

3. Good Penetration and Fine Appearance The rods provide excellent penetration, which is crucial when dealing with thicker materials. Moreover, they leave a smooth, aesthetically pleasing surface finish, which is highly appreciated in projects where appearance matters.

4. Welding in All Positions The capability to weld in all positions—flat, horizontal, vertical, and overhead—gives E6013 rods an edge over others. This flexibility allows welders to tackle various tasks without needing to switch rods frequently.

e6013 welding rods 3.2mm factory

5. Reliable Performance E6013 welding rods maintain a consistent performance, even in challenging conditions. They have low sensitivity to rust and moisture, which can be crucial in outdoor or less-than-ideal working environments.

Applications of E6013 Welding Rods

E6013 welding rods find applications across various sectors. They are commonly used in building and construction for structural welds, fabrication of light machinery, automotive repairs, and household repairs. The 3.2mm diameter variation is particularly favored for projects that require moderate penetration while ensuring a robust connection between welded surfaces.

Additionally, in the field of artistic metalworking, E6013 rods allow artists and fabricators to work on intricate designs while maintaining structural integrity. Their ease of weldability makes them a popular choice among hobbyists who often indulge in DIY projects.

Factory Production of E6013 Welding Rods

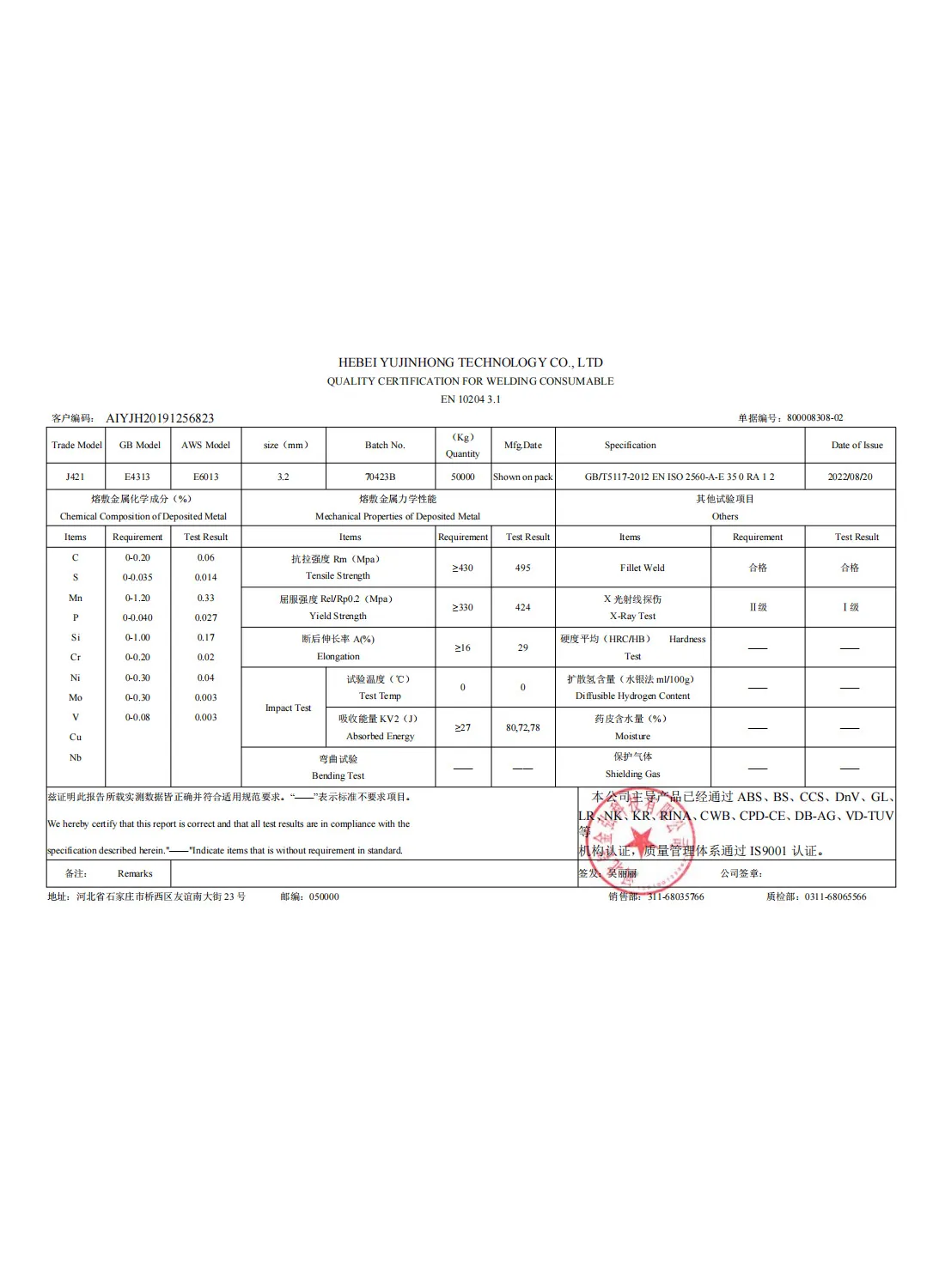

The manufacturing process of E6013 welding rods reflects the commitment to quality that is paramount in the welding industry. Factories employ advanced technologies and materials to ensure that every rod meets stringent quality standards. The production involves precision in the formulation of the coating, along with rigorous testing to guarantee consistent performance.

Quality control is a vital aspect of the manufacturing process. From testing the tensile strength to assessing the arc stability, each batch of welding rods undergoes inspection to ensure it meets the required specifications.

Conclusion

In conclusion, E6013 3.2mm welding rods represent a blend of versatility, reliability, and ease of use that resonates with welders across the globe. Their numerous advantages make them an indispensable tool in various industries, solidifying their presence as a benchmark in the welding rod market. As manufacturing processes continue to evolve, the commitment to quality in producing E6013 rods will ensure their relevance and utility in the ever-expanding world of welding.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025