E7018 Welding Electrode Manufacturing Process Overview and Key Features

E7018 Welding Electrode Factory A Cornerstone of Modern Welding

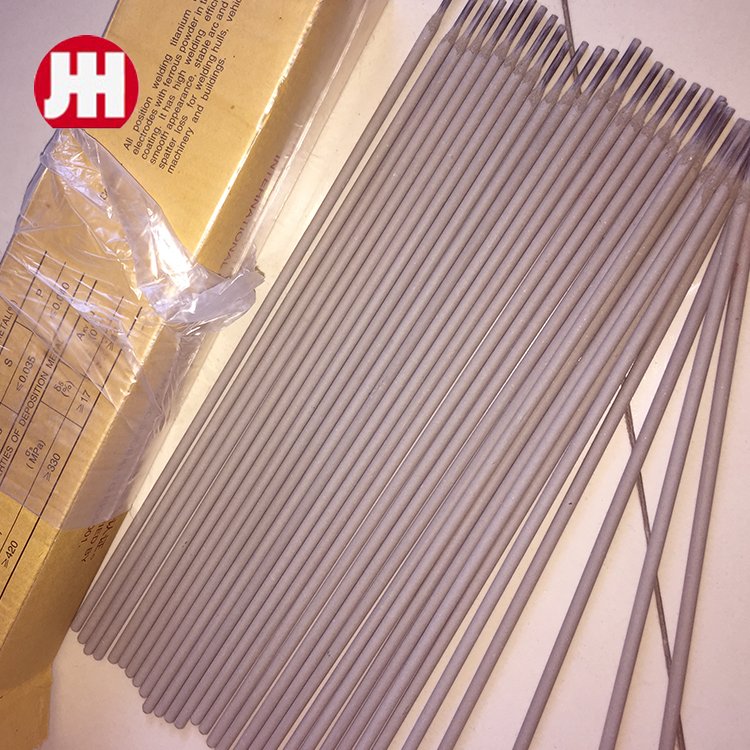

The E7018 welding electrode is an essential component in the realm of arc welding, widely used for its versatility and strength in various applications. Manufacturing these electrodes requires precision, expertise, and a deep understanding of the materials involved. An E7018 welding electrode factory plays a critical role in ensuring that these essential welding tools meet industry standards and customer needs.

E7018 electrodes are specifically designed for use in shielded metal arc welding (SMAW), offering excellent weld quality with a low hydrogen content. This characteristic is crucial as it minimizes the risk of hydrogen-induced cracking in the weld. The E7018 designation indicates that the electrode is suitable for all-position welding, making it ideal for both structural and fabrication projects.

E7018 Welding Electrode Factory A Cornerstone of Modern Welding

After selecting the appropriate materials, the steel wire is drawn to the required diameter. This step is vital as the size of the wire impacts the amount of current that can be effectively utilized during the welding process. Following this, the flux coating is carefully formulated and applied. The flux serves a dual purpose it protects the molten weld pool from atmospheric contamination and contributes to the weld's overall quality.

e7018 welding electrode factory

Once the electrodes are fabricated, they undergo rigorous testing. Quality assurance is a crucial phase in the manufacturing process, involving mechanical tests, corrosion resistance checks, and metallurgical analysis to ensure the electrodes meet the necessary standards specified by organizations such as the American Welding Society (AWS). Only after passing these tests are the electrodes deemed suitable for market distribution.

In addition to manufacturing, an E7018 welding electrode factory is responsible for research and development to enhance the performance of these electrodes continually. By collaborating with engineers and welding specialists, factories can innovate and improve upon their products, ensuring they keep pace with the evolving demands of the welding industry.

Furthermore, the factory must also focus on sustainability. With rising environmental concerns, many manufacturers are adopting eco-friendly practices in their production processes. This includes reducing waste, recycling materials, and utilizing energy-efficient technologies, demonstrating a commitment to both quality and environmental responsibility.

In conclusion, an E7018 welding electrode factory is a vital player in the welding industry. Through advanced manufacturing techniques, rigorous quality control, and a commitment to innovation and sustainability, these factories ensure that the E7018 electrodes produced meet the highest standards of performance and reliability. As welding applications continue to diversify, the significance of these factories will only grow, reinforcing their role in shaping the future of welding technology.

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025