er70s 3 welding wire suppliers

Understanding ER70S-3 Welding Wire and Its Suppliers

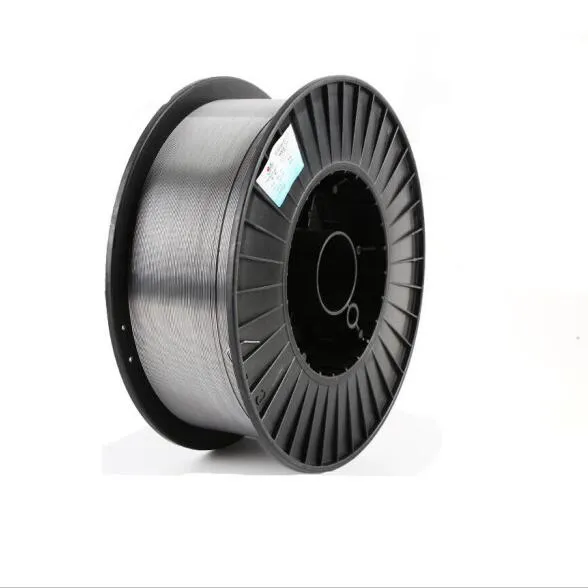

Welding is an essential process in various industries, including construction, manufacturing, and automotive. One of the most commonly used welding wires in the metal fabrication industry is ER70S-3. This article explores the characteristics of ER70S-3 welding wire, its applications, and what to look for in reputable suppliers.

What is ER70S-3 Welding Wire?

ER70S-3 is a solid mild steel welding wire that is designed for GMAW (Gas Metal Arc Welding) and FCAW (Flux-Cored Arc Welding) processes. The designation “ER” stands for “electrode” and “rod,” which indicates that it is a filler metal suitable for welding. The “70” in ER70S-3 refers to the minimum tensile strength of 70,000 psi, while the “S” denotes it is a solid wire. The “3” indicates that the wire has a composition suitable for welding a variety of steel grades.

One of the key characteristics of ER70S-3 is its excellent deoxidizing properties, which help in clean welding by minimizing contamination and ensuring a smooth, high-quality finish. The wire is typically used for welding mild steel and is suitable for a variety of applications due to its versatility. It can be used for both thin and thick materials, making it a go-to choice for many welding professionals.

Applications of ER70S-3 Welding Wire

ER70S-3 welding wire is widely used in various sectors. Its applications include

1. Structural Steel Fabrication The wire is commonly used for welding structural components in buildings, bridges, and other infrastructure projects due to its strength and reliability.

2. Manufacturing In the manufacturing sector, ER70S-3 is used for fabricating machinery, automobile frames, and other heavy equipment where strength and durability are essential.

3. Repair and Maintenance It is also frequently used for repair work on equipment and structures, offering a solid and lasting bond for repairing damaged steel components.

er70s 3 welding wire suppliers

Choosing the Right Supplier for ER70S-3 Welding Wire

Selecting the right supplier for ER70S-3 welding wire is crucial for ensuring the quality of your welding projects. Here are several factors to consider

1. Reputation and Experience Look for suppliers with a solid reputation in the industry. Research their history, customer reviews, and the breadth of their experience with welding products.

2. Quality Standards Ensure that the supplier adheres to industry standards and regulations for safety and quality. Certificates such as ISO or AWS certifications are positive indicators of a supplier's commitment to quality.

3. Variety of Products A reputable supplier should offer a broad range of welding wires, including different diameters and types, to suit various project needs.

4. Technical Support and Expertise Good suppliers provide technical support and guidance on selecting the right wire for your specific application. Their expertise can help ensure that you achieve the best results in your welding projects.

5. Pricing and Availability While cost should not be the sole determining factor, it's essential to find a supplier that offers competitive pricing and reliable availability. This ensures that you can acquire the necessary materials when you need them.

6. Customer Service Evaluate the quality of customer service provided by the supplier. Quick responses, knowledgeable staff, and after-sale support can significantly enhance your purchasing experience.

Conclusion

ER70S-3 welding wire is a versatile and dependable choice for a wide range of applications in the welding industry. By choosing a reputable supplier that meets your specific needs, you can ensure the quality of your welding projects. With the right materials and expertise, you can achieve high-quality results in your welding endeavors. Always remember, the foundation of a successful welding project begins with choosing the right welding wire and an excellent supplier.

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025