High-Quality ER70S-6 1.0mm Welding Wire for Reliable Metal Joining Solutions

Understanding ER70S-6 Welding Wire A Comprehensive Overview

Welding plays a critical role in various industries, including construction, manufacturing, and automotive. One essential component in the welding process is the welding wire, which comes in various types and specifications. Among these, ER70S-6 welding wire is particularly popular due to its versatile applications and superior performance. In this article, we will explore the characteristics, advantages, and common uses of 1.0mm ER70S-6 welding wire.

What is ER70S-6 Welding Wire?

ER70S-6 is a commonly used solid welding wire alloy composed primarily of iron with additions of manganese, silicon, and carbon. The ER stands for Electrode Rod, indicating its application in welding while also signifying that it is intended for use in GMAW (Gas Metal Arc Welding) processes. The 70 indicates that the wire has a minimum yield strength of 70,000 psi, while the S refers to its solid form without any coating. The -6 denotes the specific chemical composition and mechanical properties that make it suitable for a wide range of welding applications.

Characteristics of 1.0mm ER70S-6 Welding Wire

1. Diameter The 1.0mm diameter is a standard size that allows for precise control during the welding process. This size is ideal for both thin and medium-thickness materials, facilitating a fine bead and minimal distortion in the welded joint.

2. Composition ER70S-6 welding wire contains a higher level of manganese and silicon compared to other ER70S wires. This composition enhances its deoxidation properties, making it particularly effective for welding steel that might have surface impurities.

3. Versatility The wire is compatible with a variety of shielding gases, such as argon and carbon dioxide. This versatility allows welders to adapt their settings for different environments and material types.

4. Weld Quality The use of ER70S-6 generally results in welds with excellent quality and appearance, characterized by strong, clean beads with minimal spatter. The wire’s ability to accommodate different welding techniques makes it favorable for both novice and experienced welders.

Advantages of Using ER70S-6

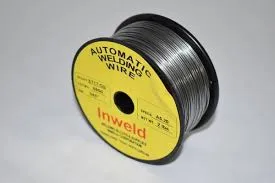

welding wire er70s-6 1.0mm

1. High Yield Strength With a yield strength of 70,000 psi, ER70S-6 provides robust joints that can withstand significant stress and tensile loads, making it ideal for structural applications.

2. Good Fluidity The wire's composition ensures excellent fluidity when molten, leading to better penetration in the base material and promoting stronger welds.

3. Resistance to Slag Inclusion The improved deoxidation properties of ER70S-6 reduce the likelihood of slag inclusion during the welding process, resulting in cleaner, high-quality welds.

4. Wide Application Range ER70S-6 can be used for welding carbon steels, mild steels, low-alloy steels, and even in some cases, stainless steels. This wide range makes it a preferred choice in various sectors, including construction and automotive manufacturing.

Common Applications

1. Structural Steel Fabrication Due to its strength and weld quality, ER70S-6 is frequently used in the fabrication of structural steel components for buildings and bridges.

2. Manufacturing The wire is extensively used in the manufacturing of machinery and equipment due to its reliability and ability to form strong joints.

3. Automotive Repairs Many automotive repair shops prefer ER70S-6 for MIG welding because it offers good quality welds on automotive components.

Conclusion

In summary, 1.0mm ER70S-6 welding wire is an essential tool for welders seeking high-quality, versatile, and reliable welding solutions. Its strong mechanical properties, excellent fluidity, and resistance to defects make it a go-to choice for various applications in construction and manufacturing. Understanding the characteristics and benefits of ER70S-6 can help professionals select the right materials for their welding projects, ensuring the durability and integrity of their work.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025