wholesale aluminum welding rod factories

The Essential Guide to Wholesale Aluminum Welding Rod Factories

Aluminum welding is a vital process in various industries, from automotive to aerospace, due to its lightweight and corrosion-resistant properties. As the demand for aluminum products continues to rise, the need for high-quality aluminum welding rods has never been more critical. This article explores the wholesale aluminum welding rod factories, their production processes, and their significance in the modern industrial landscape.

Understanding Aluminum Welding Rods

Aluminum welding rods are consumable materials used to join aluminum components. They play a crucial role in the welding process, helping to create strong, durable bonds. The quality of these rods directly influences the overall strength and integrity of the welded structures. Aluminium welding rods come in various alloys, each suited for different applications—whether for thin sheet materials or heavier structural components.

Importance of Wholesale Factories

Wholesale factories are essential in the supply chain of welding rods. They produce these rods in large quantities, enabling businesses to purchase them at reduced costs, which is particularly important for small and medium-sized enterprises (SMEs) aiming to minimize expenses while maximizing quality.

Benefits of Sourcing from Wholesale Factories

1. Cost Efficiency Wholesale purchasing provides significant savings on raw materials. Factories can produce aluminum welding rods at scale, translating into lower prices for buyers.

2. Quality Control Established factories adhere to industry standards and regulations, ensuring that their products meet quality benchmarks. They implement rigorous quality control measures and testing protocols, providing peace of mind to customers.

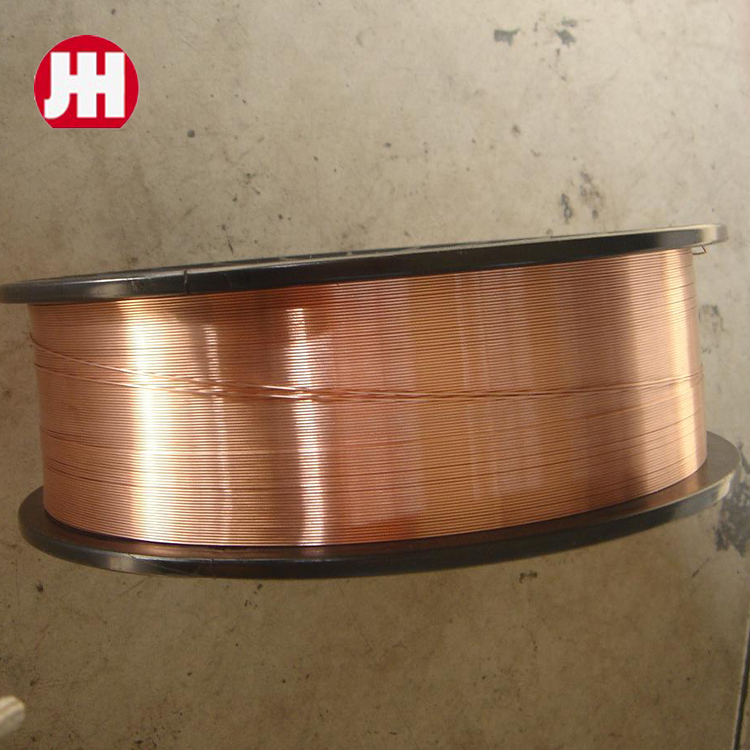

3. Variety of Products Wholesale factories typically offer a vast selection of welding rods tailored to diverse applications. From TIG welding rods to MIG wires, customers can find products that meet their specific needs.

4. Customization Options Many wholesale manufacturers provide customization services, allowing businesses to order rods in specific lengths, diameters, and alloy compositions.

5. Supply Reliability Partnering with a wholesale factory ensures a steady supply of welding rods, crucial for businesses operating in industries where downtime can lead to significant losses.

wholesale aluminum welding rod factories

The Production Process of Aluminum Welding Rods

The manufacturing process of aluminum welding rods involves several key steps

1. Material Selection Factories begin by selecting high-quality aluminum alloys based on the desired characteristics of the final product, such as strength, ductility, and corrosion resistance.

2. Melting and Casting The selected aluminum alloy is melted in a furnace. Once liquid, the alloy is cast into rods, using either extrusion or continuous casting methods, depending on the required specifications.

3. Cold Working and Drawing After casting, the rods undergo cold working processes, including drawing and reducing to achieve the desired diameter and mechanical properties.

4. Heat Treatment Certain alloys may require heat treatment to enhance their performance characteristics. This step is essential for achieving optimal strength and ductility.

5. Surface Finishing Finally, the rods may undergo surface treatments to improve their resistance to oxidation and enhance their appearance. Processes such as anodizing or coating are commonly employed.

The Future of Aluminum Welding Rods

With the increasing emphasis on lightweight materials in various industries, the demand for aluminum welding rods is expected to grow. Innovations in manufacturing processes and advancements in alloy compositions may lead to new, improved welding rods that enhance performance and durability.

Moreover, as industries strive for sustainability, wholesale aluminum welding rod factories are likely to adopt eco-friendly practices, such as recycling scrap aluminum and using energy-efficient manufacturing techniques. This shift not only minimizes environmental impact but also aligns with the growing consumer demand for sustainable products.

Conclusion

Wholesale aluminum welding rod factories play a pivotal role in the modern industrial landscape, providing essential materials that fuel various sectors. By understanding their significance, benefits, and production processes, businesses can make informed decisions when sourcing welding rods. As industries continue to evolve, the collaboration between manufacturers and consumers will be vital to achieving quality, efficiency, and sustainability in aluminum welding applications.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025