wholesale mig fluxed wires manufacturers

The Evolution of Wholesale MIG Fluxed Wires Manufacturers

In today's competitive welding industry, the demand for high-quality materials has led to a significant evolution in wholesale manufacturers of MIG fluxed wires. The MIG (Metal Inert Gas) welding process is widely used across various sectors, including automotive, construction, and manufacturing, due to its efficiency and versatility. As a result, manufacturers are continually innovating to meet the specific needs of their customers while ensuring their products stand out in the market.

Understanding MIG Fluxed Wires

MIG fluxed wires are a type of filler material used in the MIG welding process. Unlike solid wires, flux-cored wires contain a flux that provides a shielding effect to protect the weld pool from contamination by atmospheric gases. This feature allows for better penetration and improves overall weld quality, making fluxed wires a preferred choice for many welding applications. The usage of these wires not only enhances the performance of welds in terms of strength and durability but also increases efficiency, enabling welders to complete their tasks more swiftly.

The Role of Wholesale Manufacturers

Wholesale MIG fluxed wires manufacturers play a crucial role in the supply chain by providing high-quality materials at competitive prices. They work closely with consumers, from small welding shops to large industrial clients, ensuring that they have access to the necessary products to carry out their projects effectively. These manufacturers often provide a variety of wire diameters, flux compositions, and packaging options to cater to different welding requirements.

Moreover, with the rise of e-commerce, many manufacturers have adopted online marketplaces, making it easier for buyers to compare products, read reviews, and place orders with just a few clicks. This shift towards digital platforms has revolutionized how manufacturers interact with their customers, leading to increased sales and broader market reach.

Innovative Practices and Quality Control

wholesale mig fluxed wires manufacturers

As the industry evolves, so do the practices implemented by wholesale manufacturers. Many have adopted advanced manufacturing techniques and quality control measures to ensure that their products meet international standards. This includes the use of automated welding processes, real-time quality checks, and adherence to stringent safety regulations.

Additionally, manufacturers are increasingly investing in research and development to create wires that offer enhanced performance characteristics. This includes producing wires that are more resistant to spatter, have improved arc stability, and offer superior feedability. By continually improving their product offerings, manufacturers can better serve their customers and stay ahead of the competition.

Environmental Considerations

In recent years, the welding industry has faced increasing pressure to adopt environmentally friendly practices. Many wholesale MIG fluxed wires manufacturers are responding by developing products that minimize environmental impact. This includes the use of sustainable materials and the reduction of harmful emissions during the manufacturing process.

Moreover, some manufacturers are exploring the potential of alternative welding technologies, such as electric arc welding, which can be more energy-efficient and produce fewer pollutants. By embracing sustainable practices, manufacturers not only contribute to environmental protection but also appeal to a growing market of eco-conscious consumers.

The Future of MIG Fluxed Wires Manufacturing

Looking ahead, the future of wholesale MIG fluxed wires manufacturers appears bright. With the continued growth of the construction and manufacturing sectors, the demand for high-quality welding materials will remain strong. Manufacturers that prioritize innovation, sustainability, and customer service will likely lead the way in this evolving market.

In conclusion, the landscape of wholesale MIG fluxed wires manufacturing is characterized by a commitment to quality, efficiency, and environmental responsibility. As manufacturers continue to innovate and adapt to the changing needs of the industry, they will play a pivotal role in shaping the future of welding practices. Whether through advancements in product development or enhanced customer engagement strategies, these manufacturers are positioned to thrive in a dynamic marketplace.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

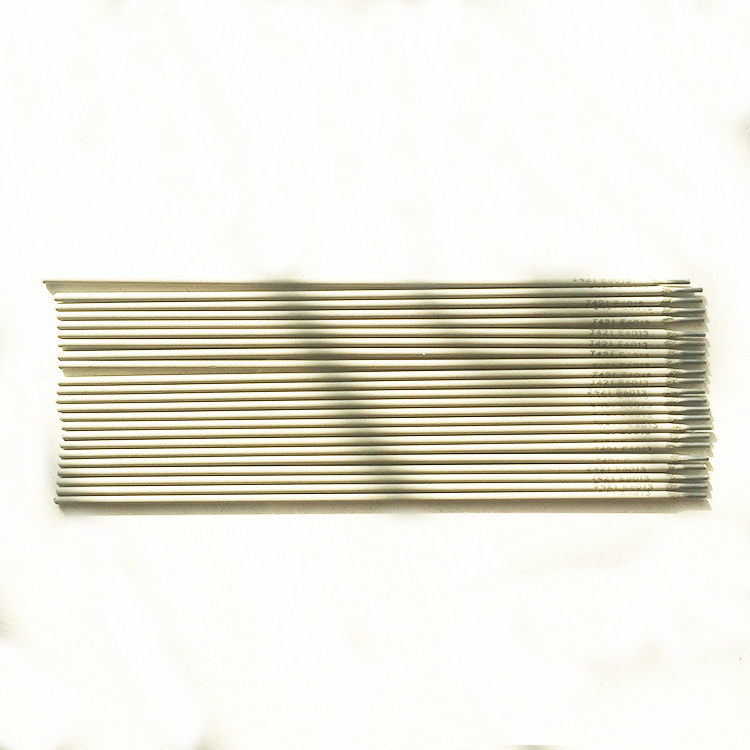

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025