Feb . 17, 2025 18:23

Back to list

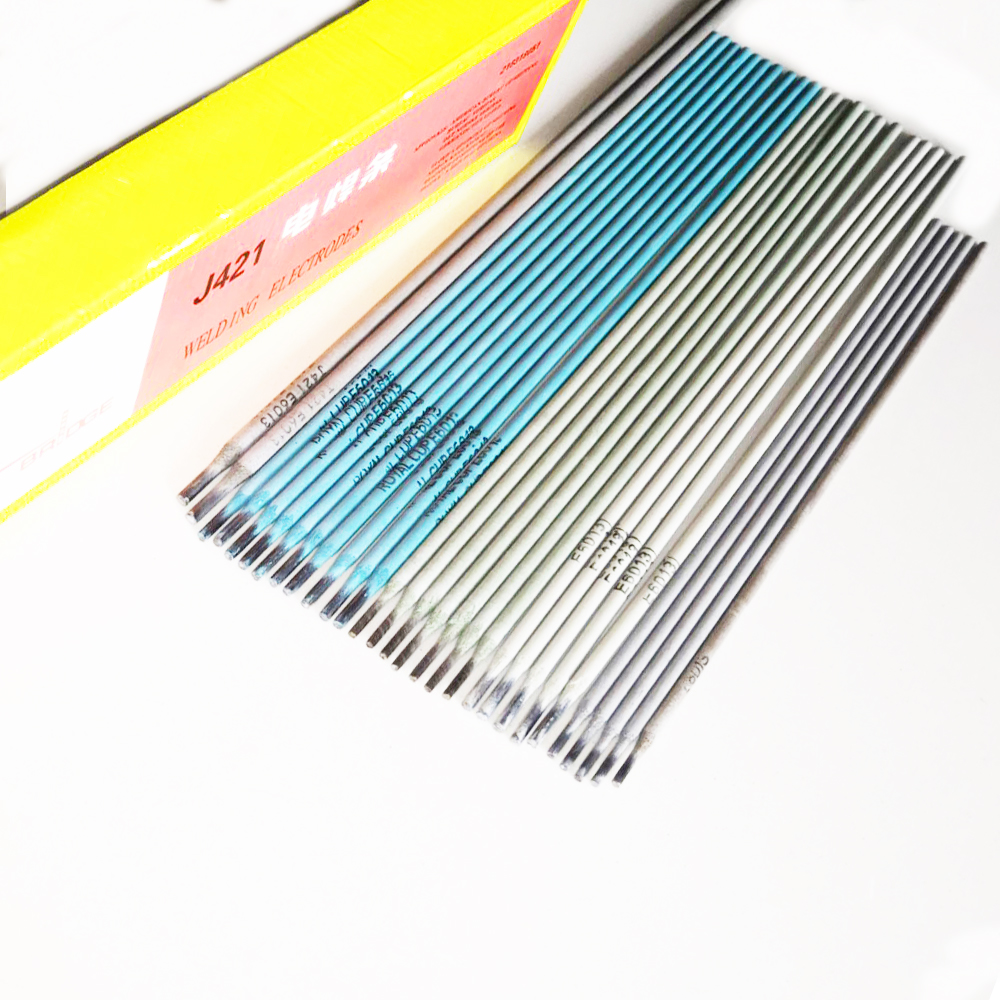

wholesale tig mig welding wire

Choosing the right welding wire is crucial for ensuring high-quality welding results, whether for industrial or personal projects. Wholesale TIG and MIG welding wires have gained popularity due to their effectiveness and cost efficiency. As an expert in the industry, with years of hands-on experience, here is an exploration into the key aspects that make these wires essential for welding enthusiasts and professionals.

Wholesale providers of MIG wires offer grades suited for various applications—from home DIY projects to industrial manufacturing. Their expertise in metallurgy ensures that each batch of wire provides optimal ductility, tensile strength, and resistance to corrosion, significantly impacting the lifespan of the welds. High-caliber MIG wires maximize productivity and ensure the welder’s work is above reproach, making them indispensable in professional settings. Establishing authoritative credibility in sourcing TIG and MIG wires involves partnering with suppliers who can provide certification and adherence to international standards. Trust is built through transparent sourcing processes, where the origin of materials and manufacturing practices are openly shared. Working with suppliers that prioritize quality assurance guarantees that each roll of wire meets the requisite performance standards, thus fostering trust and long-term relationships with end-users. Professional welding demands not only experience and precision but also the guarantee of materials that meet rigorous industry benchmarks. Welders need assurance that their materials will withstand both the test of application and the test of time. Connoisseurs in welding wire manufacturing understand the symbiotic relationship between wire quality and weld quality. Thus, wholesale suppliers often offer technical support and expertise, advising on appropriate wire choices depending on the welding task at hand. In conclusion, the wholesale purchase of TIG and MIG welding wires represents a sophisticated approach to welding, combining economic sense with high standards of performance. It allows professionals and hobbyists alike to achieve extraordinary results—not merely by providing a plentiful supply but by ensuring each wire’s consistency and reliability. Trustworthy suppliers empower welders with products that embody precision, durability, and safety, turning every weld into a masterpiece of craftsmanship. Opting for wholesale TIG and MIG welding wires is a strategic decision that underscores the value of quality and expertise in welding endeavors.

Wholesale providers of MIG wires offer grades suited for various applications—from home DIY projects to industrial manufacturing. Their expertise in metallurgy ensures that each batch of wire provides optimal ductility, tensile strength, and resistance to corrosion, significantly impacting the lifespan of the welds. High-caliber MIG wires maximize productivity and ensure the welder’s work is above reproach, making them indispensable in professional settings. Establishing authoritative credibility in sourcing TIG and MIG wires involves partnering with suppliers who can provide certification and adherence to international standards. Trust is built through transparent sourcing processes, where the origin of materials and manufacturing practices are openly shared. Working with suppliers that prioritize quality assurance guarantees that each roll of wire meets the requisite performance standards, thus fostering trust and long-term relationships with end-users. Professional welding demands not only experience and precision but also the guarantee of materials that meet rigorous industry benchmarks. Welders need assurance that their materials will withstand both the test of application and the test of time. Connoisseurs in welding wire manufacturing understand the symbiotic relationship between wire quality and weld quality. Thus, wholesale suppliers often offer technical support and expertise, advising on appropriate wire choices depending on the welding task at hand. In conclusion, the wholesale purchase of TIG and MIG welding wires represents a sophisticated approach to welding, combining economic sense with high standards of performance. It allows professionals and hobbyists alike to achieve extraordinary results—not merely by providing a plentiful supply but by ensuring each wire’s consistency and reliability. Trustworthy suppliers empower welders with products that embody precision, durability, and safety, turning every weld into a masterpiece of craftsmanship. Opting for wholesale TIG and MIG welding wires is a strategic decision that underscores the value of quality and expertise in welding endeavors.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025