-

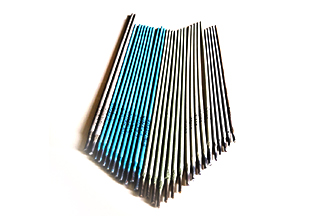

Choosing the Right Wholesale Welding Electrodes J421 Supplier for Your Business When it comes to weEn savoir plus

Choosing the Right Wholesale Welding Electrodes J421 Supplier for Your Business When it comes to weEn savoir plus -

As the world becomes increasingly industrialized, the demandAs the world becomes increasingly industEn savoir plus

As the world becomes increasingly industrialized, the demandAs the world becomes increasingly industEn savoir plus -

Navigating the Landscape of China Welding Rod Suppliers In the vast and dynamic market of industriaEn savoir plus

Navigating the Landscape of China Welding Rod Suppliers In the vast and dynamic market of industriaEn savoir plus -

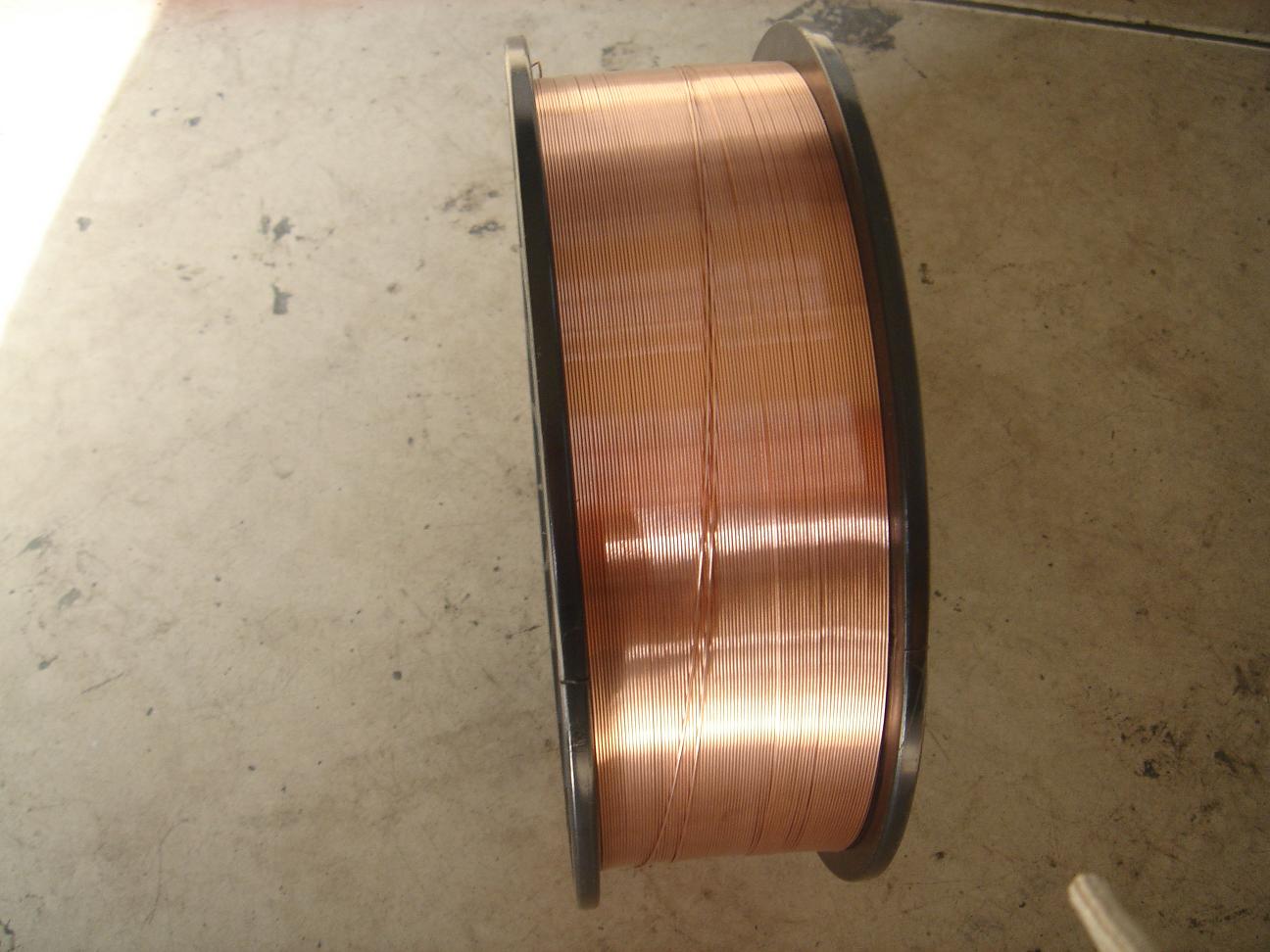

Choosing the Right Wholesale MIG Wire Sizes Supplier When it comes to welding projects, selecting tEn savoir plus

Choosing the Right Wholesale MIG Wire Sizes Supplier When it comes to welding projects, selecting tEn savoir plus -

Choosing the Right Wholesale Welding Rod Supplier In the world of welding, selecting the appropriatEn savoir plus

Choosing the Right Wholesale Welding Rod Supplier In the world of welding, selecting the appropriatEn savoir plus -

China's Electrodes and Wire Manufacturing Industry A Global Powerhouse China has long been recognizEn savoir plus

China's Electrodes and Wire Manufacturing Industry A Global Powerhouse China has long been recognizEn savoir plus -

The Evolution of China's ER4043 Welding Wire Manufacturing Industry The manufacturing sector in ChiEn savoir plus

The Evolution of China's ER4043 Welding Wire Manufacturing Industry The manufacturing sector in ChiEn savoir plus -

Choosing the Right 0.035% E20 Welding Wire Manufacturer In the vast expanse of industrial manufactuEn savoir plus

Choosing the Right 0.035% E20 Welding Wire Manufacturer In the vast expanse of industrial manufactuEn savoir plus -

Exploring the World of Mig Welding Electrode Manufacturers MIG welding, also known as Metal Inert GEn savoir plus

Exploring the World of Mig Welding Electrode Manufacturers MIG welding, also known as Metal Inert GEn savoir plus -

A Glimpse into China's 3.25mm Welding Rod Manufacturing Landscape The manufacturing sector in ChinaEn savoir plus

A Glimpse into China's 3.25mm Welding Rod Manufacturing Landscape The manufacturing sector in ChinaEn savoir plus -

Exploring the Versatility of J421 Welding Electrodes The J421 welding electrode is a staple in theEn savoir plus

Exploring the Versatility of J421 Welding Electrodes The J421 welding electrode is a staple in theEn savoir plus -

The Versatile Flux Core Welding Wire 035 In the world of welding, choosing the right wire is cruciaEn savoir plus

The Versatile Flux Core Welding Wire 035 In the world of welding, choosing the right wire is cruciaEn savoir plus