308 welding electrode factories

The manufacturing of welding electrodes is a vital component in the welding industry, as these electrodes are essential for establishing strong, durable, and efficient welds in various applications. Among the key players in this sector, the 308 welding electrode factory stands out due to its specialization in producing high-quality electrodes suitable for different types of stainless steel welding.

The 308 welding electrode is primarily used for welding type 304 stainless steel, which is the most widely used stainless steel grade, known for its good corrosion resistance and formability. The electrodes are designed to provide excellent mechanical properties and are characterized by their ability to resist oxidation and retain strength at elevated temperatures. In a typical 308 electrode, the core wire is made from austenitic stainless steel, and the coating helps stabilize the arc and improve the appearance of the weld bead.

Factories specializing in 308 welding electrodes focus on several critical aspects of production. First, they ensure that the raw materials used in the manufacturing process adhere to strict quality standards. High-purity stainless steel is sourced to guarantee that the final product meets performance criteria. Additionally, significant investment in modern manufacturing processes and technologies allows these factories to maintain consistency and quality in their products.

Moreover, research and development play a crucial role in the operations of a 308 welding electrode factory. Engineers and technicians constantly analyze the performance of the electrodes in various welding conditions and seek to develop formulas that can enhance their characteristics. Innovations might involve altering the chemical composition of the electrode or improving the coating process to ensure optimal performance.

308 welding electrode factories

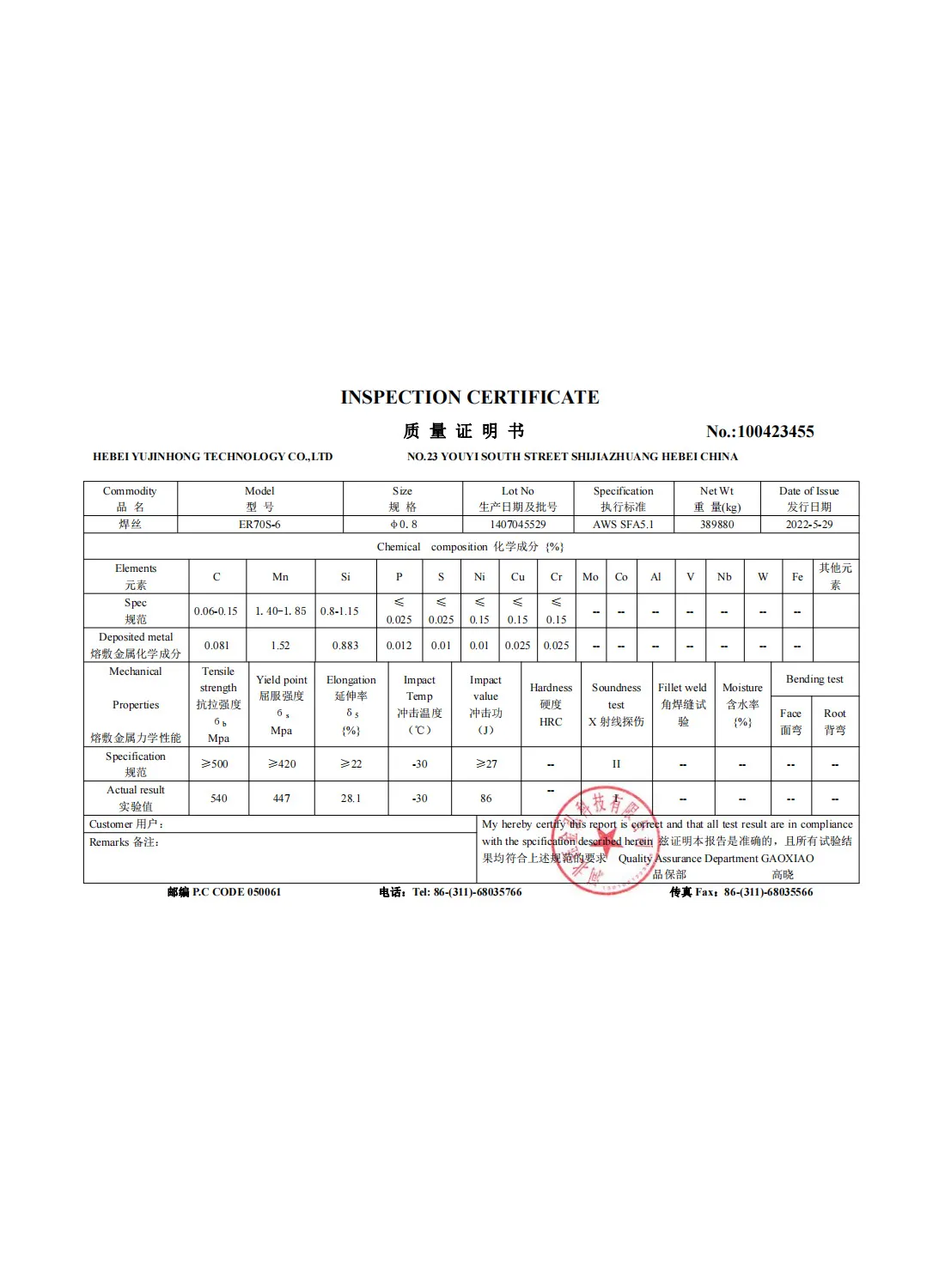

Quality control is another essential aspect of manufacturing. Each batch of electrodes undergoes rigorous testing to ensure they meet the required specifications. This may include tensile testing, impact testing, and examination of the welds produced. By adhering to international standards such as AWS (American Welding Society) and ISO certifications, these factories assure customers of the reliability and effectiveness of their products.

In recent years, the demand for welding materials has been on the rise due to the growth of industries such as construction, automotive, and shipbuilding. Consequently, 308 welding electrode factories are dedicated not just to increasing production capacity but also to enhancing product performance and sustainability. For instance, some manufacturers are exploring environmentally friendly alternatives to traditional coating materials, striving to reduce their environmental footprint.

In conclusion, 308 welding electrode factories are vital for the production of high-quality welding materials. By focusing on material quality, advanced manufacturing practices, rigorous testing, and innovation, these facilities contribute significantly to the efficiency and effectiveness of welding operations across various industries. Their commitment to excellence ensures that welders can rely on their products to deliver strong, lasting joints in a wide array of applications.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025