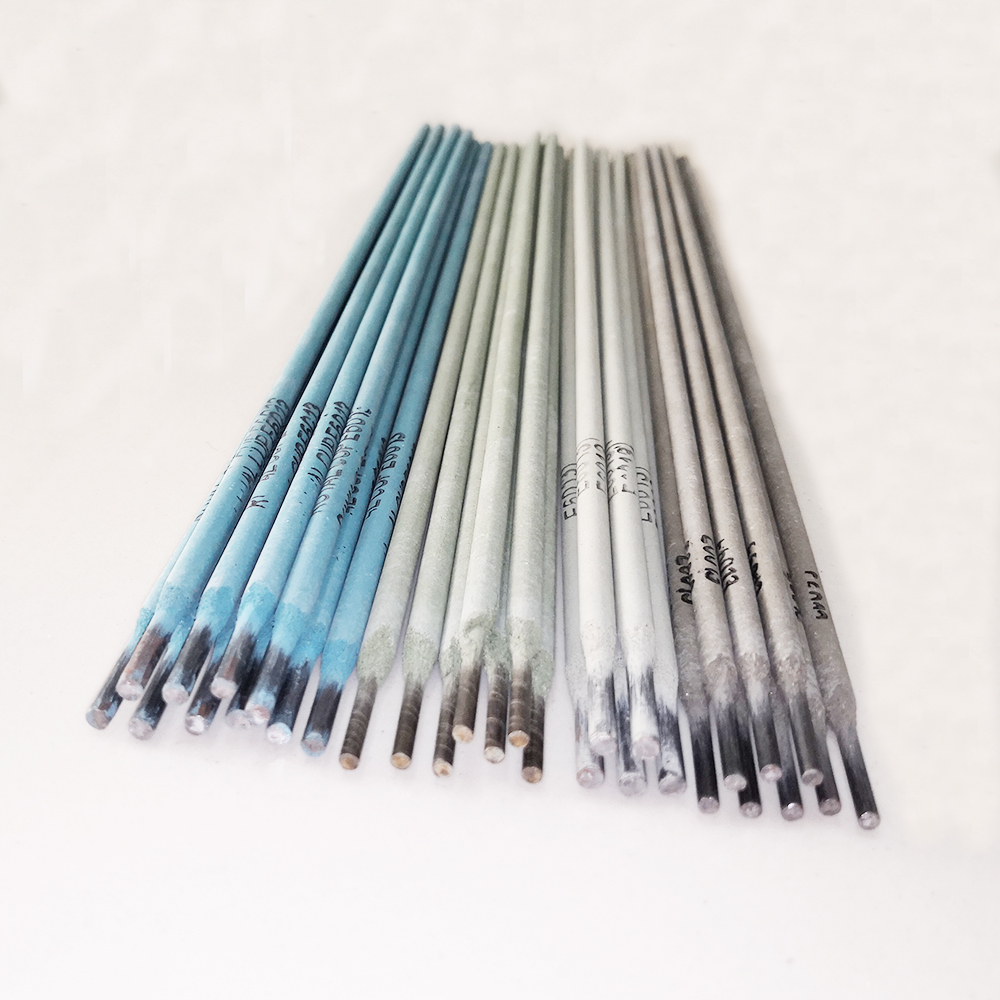

4043 stick welding rod supplier

Understanding 4043 Stick Welding Rods A Comprehensive Guide for Suppliers

Welding is a crucial process in various industries, ranging from automotive to aerospace, and the type of welding rods used can significantly influence the quality of the weld. Among the diverse range of welding rods, 4043 stick welding rods stand out due to their specific composition and intended applications. In this article, we will delve into the characteristics of 4043 welding rods, their applications, and insights for suppliers.

What is a 4043 Welding Rod?

4043 welding rods are made from an aluminum-silicon alloy, a blend that offers several advantageous properties. This alloy consists primarily of aluminum (90-93%) and silicon (5-7%). The presence of silicon lowers the melting point of the alloy and improves fluidity, making it particularly suitable for welding aluminum and its alloys. The unique composition gives 4043 rods excellent corrosion resistance, good weldability, and a favorable appearance after welding.

Advantages of Using 4043 Welding Rods

1. Versatility One of the most notable features of 4043 rods is their versatility. They can be used for various applications, including automotive repairs, construction, and artistic metalwork. They are particularly effective for welding aluminum castings, which makes them a preferred choice for manufacturers and repair shops.

2. Excellent Finish The 4043 alloy provides a smooth, clean finish that reduces the need for extensive post-weld processing. This characteristic is especially beneficial in applications where aesthetic appearance is crucial.

3. Good Fluidity The silicon content in 4043 welding rods aids in achieving good fluidity during the welding process. As a result, weld pools formed with these rods flow easily and can fill gaps effectively, which is critical for achieving strong welds in complex joints.

4. Corrosion Resistance Aluminum naturally resists corrosion, and this property is enhanced in the 4043 alloy. Welding with these rods ensures that the welded areas retain a level of protection against environmental elements, making them suitable for outdoor and marine applications.

Applications of 4043 Welding Rods

Several industries utilize 4043 welding rods extensively. Some of the key applications include

- Automotive Industry For repairs and the manufacture of aluminum bodies, 4043 rods are favored due to their compatibility with aluminum components

.4043 stick welding rod supplier

- Aerospace In aerospace manufacturing, the lightweight and strong characteristics of aluminum make these rods invaluable for joining parts without adding excessive weight.

- Marine Applications Given their corrosion resistance, 4043 rods are ideal for repairs on boats and other marine equipment.

- Construction From aluminum frames to roofing, the durability and strength of 4043 welds make them suitable for structural applications.

Tips for Suppliers Supplying 4043 Welding Rods

As a supplier of 4043 welding rods, understanding the product and its market trends is vital. Here are several key considerations

1. Quality Assurance Ensure that the rods meet industry standards and specifications. Quality assurance processes, including certifications and testing, are fundamental to building trust with clients.

2. Customer Education Provide resources for customers regarding the proper use of 4043 rods, including welding techniques and safety precautions. Well-informed customers are more likely to achieve successful results and provide repeat business.

3. Inventory Management Keep a comprehensive stock of various sizes and quantities of 4043 rods to meet diverse customer needs. Quick and efficient order fulfillment can significantly enhance customer satisfaction.

4. Market Trends Stay updated on industry trends and emerging technologies in welding. This knowledge can help you adjust your product offerings and marketing strategies accordingly.

Conclusion

4043 stick welding rods are an essential tool in the welder’s arsenal, offering a perfect blend of strength, durability, and aesthetic appeal. As a supplier, understanding these rods’ characteristics and applications can significantly enhance your offerings and business success. By ensuring quality, educating customers, and staying attuned to market dynamics, you can establish a strong presence in the competitive welding supply industry. Embrace the potential of 4043 welding rods, and cater effectively to the evolving needs of your clientele.

-

China MIG Wire Manufacturers High-Quality & Durable Welding SolutionsNewsMay.14,2025

-

E71T11 Welding Wire High-Quality Flux-Cored Wire Supplier ChinaNewsMay.14,2025

-

2mm Arc Welding Rods High-Strength Aluminium Welding SolutionsNewsMay.14,2025

-

1.2mm Stainless MIG Wire Supplier Durable & Corrosion-ResistantNewsMay.13,2025

-

2.5mm 7018 Welding Electrodes - China Factory & Wholesale SupplierNewsMay.13,2025

-

Premium MIG Welder Wire Supplier China Wholesale FactoryNewsMay.13,2025