High-Quality MIG Welding Wire Manufacturer - Premium Welding Solutions

Understanding China’s MIG Wire Manufacturers

MIG (Metal Inert Gas) welding is a popular welding technique that utilizes a continuous wire feed and an inert gas to protect the weld pool from contamination. This method is widely used in various industries, including automotive, manufacturing, and construction, due to its efficiency and versatility. Among the global players in MIG wire production, China has emerged as a key manufacturer, delivering a significant volume of high-quality products.

China's MIG wire manufacturers are known for their advanced production technologies and competitive pricing. With a well-established manufacturing infrastructure, these companies cater to both domestic and international markets. They produce a wide range of MIG wires, including solid wires, flux-cored wires, and stainless steel options, tailored to meet the diverse needs of welding applications.

Understanding China’s MIG Wire Manufacturers

In addition to cost, Chinese MIG wire manufacturers prioritize adhering to international quality standards. Many of these companies have received certifications, such as ISO 9001, which ensures that their products meet rigorous quality management standards. These certifications reflect a commitment to producing reliable and durable MIG wires that withstand various welding conditions, enhancing the safety and efficiency of welding operations.

china mig wire manufacturer

Moreover, China's MIG wire industry is characterized by continuous innovation and research and development. Manufacturers are investing in advanced technologies and equipment to improve the performance of their wires. For instance, the development of specialty wires that exhibit enhanced characteristics such as better feedability and reduced spatter is gaining traction. This focus on innovation not only meets the evolving demands of the market but also positions Chinese manufacturers at the forefront of the welding supply industry.

Another critical aspect of China’s MIG wire manufacturing is its capacity for customization. Manufacturers often collaborate with clients to create bespoke solutions tailored to specific applications and industry requirements. This flexibility allows them to cater to a wide range of sectors, from shipbuilding to pipeline construction.

However, it is essential for buyers to conduct thorough due diligence when sourcing MIG wires from China. Researching potential suppliers, reviewing customer testimonials, and assessing product specifications can ensure that businesses procure high-quality materials. Establishing a strong relationship with a reputable manufacturer can lead to more favorable terms, including bulk pricing and improved service.

In conclusion, China’s MIG wire manufacturers play a significant role in the global welding supply chain. Their competitive pricing, commitment to quality, focus on innovation, and capacity for customization make them an attractive option for businesses around the world. As the demand for efficient and reliable welding materials continues to grow, China is poised to maintain its status as a leading MIG wire production hub.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

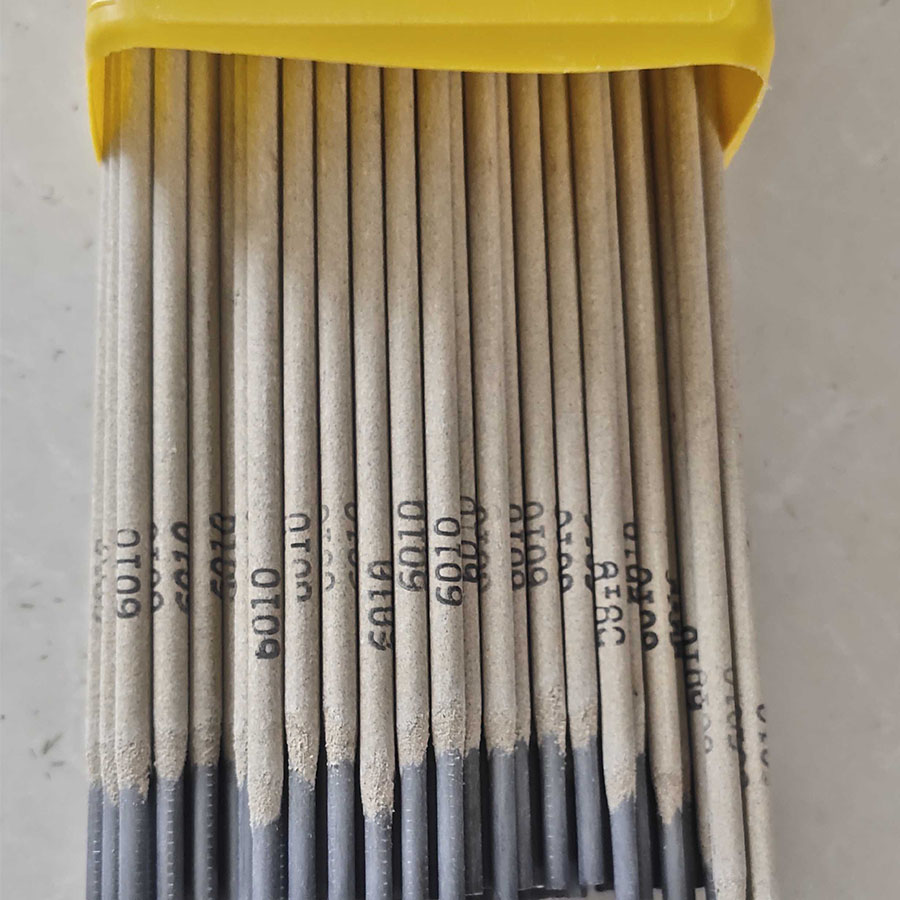

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025