china 7018 welding rod 3 32 manufacturers

An Overview of China 7018 Welding Rod Manufacturers

Welding has always been a critical component in various industries, from construction to manufacturing. Among the plethora of welding rods available, the China 7018 welding rod stands out due to its reliable performance and versatility. This article delves into the profile of manufacturers producing 7018 welding rods in China, examining their production processes, quality assurance, and market reach.

What is the 7018 Welding Rod?

The 7018 welding rod is a type of low-hydrogen electrode widely used in arc welding for its ability to produce high-quality welds. The 70 in its designation indicates that the rod can produce welds with a minimum tensile strength of 70,000 psi, while the 18 signifies the chemical composition of the rod, including iron powder and deoxidizers that enhance its usability. This rod is particularly favored for welding structural steel and low-alloy steels due to its excellent crack resistance and low hydrogen content, which minimizes the risk of cold cracking.

The Production of 7018 Welding Rods in China

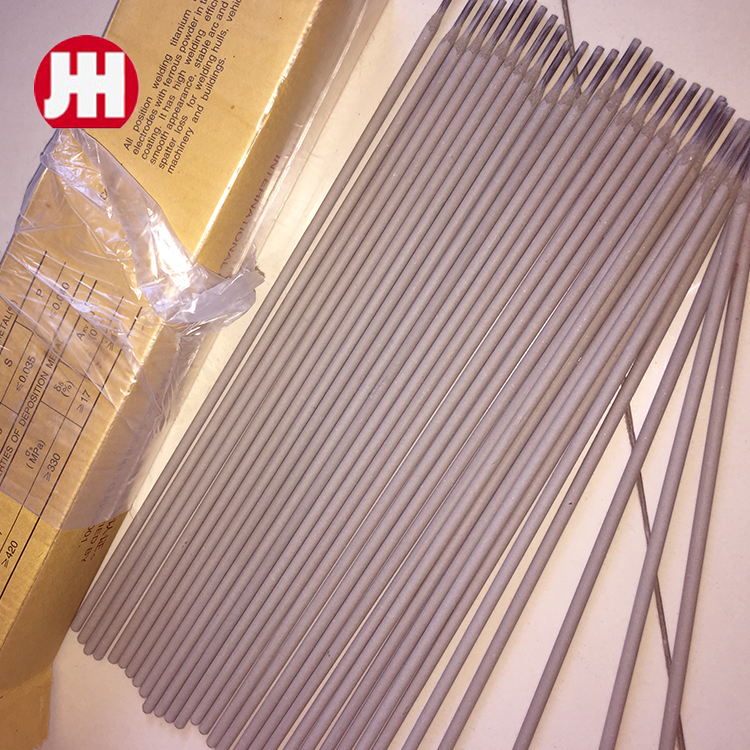

China is one of the leading manufacturers of welding rods, and the production of 7018 rods is no exception. The manufacturing process involves several stages, including selecting raw materials, mixing, extruding, and coating. Manufacturers strive to use high-quality materials to ensure the final product meets international welding standards.

Companies in China employ advanced technologies and automated processes to enhance production efficiency. The integration of quality control systems throughout manufacturing ensures that each batch of welding rods maintains consistent quality and performance characteristics.

Quality Assurance Measures

To compete in global markets, Chinese 7018 welding rod manufacturers implement rigorous quality assurance measures. These measures include

china 7018 welding rod 3 32 manufacturers

1. Material Inspection Raw materials are carefully inspected for quality. This step is crucial since the properties of the final product are heavily dependent on the quality of the materials used.

2. In-Process Testing During the production phase, various tests are conducted to monitor the physical and chemical properties of the welding rods. This includes tensile strength tests, bend tests, and impact toughness evaluations.

3. Final Inspection After production, welding rods undergo a final inspection. This includes checking for consistency in diameter, coating integrity, and overall appearance before packaging for shipment.

Market Reach and Impact

Chinese manufacturers have successfully established a strong foothold in both domestic and international markets. The competitive pricing, coupled with the quality of 7018 welding rods, has allowed these companies to export their products to various regions, including Europe, North America, and Southeast Asia.

In recent years, the demand for high-quality welding rods has surged, driven primarily by infrastructure development and the rising need for durable materials in construction projects. As a result, Chinese 7018 welding rod manufacturers are continually evolving, investing in research and development to enhance their offerings.

Conclusion

The landscape of 7018 welding rod manufacturing in China reflects a commitment to quality and innovation. With advanced production techniques, stringent quality controls, and a focus on meeting global standards, Chinese manufacturers are poised to not only meet domestic needs but also cultivate a strong presence in the international market. Whether for heavy-duty construction or intricate fabrication, the China 7018 welding rod remains a reliable choice for welders around the world.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025