china j421 electrode welding supplier

Exploring the China J421 Electrode Welding Supplier A Key Player in the Welding Industry

In the dynamic world of manufacturing and construction, the importance of effective welding cannot be overstated. Among the various types of welding consumables, the J421 electrode has emerged as a cornerstone for many welding applications, especially in the realm of general fabrication and structural welding. As industries continue to expand globally, the demand for high-quality welding electrodes, particularly the J421, has spurred the rise of specialized suppliers, particularly in China.

The J421 electrode, categorized as an E6013 type, is well-known for its versatility and performance. This type of electrode is primarily used for both AC and DC welding and is suitable for welding low-carbon steels. Its composition allows for a smooth, stable arc with minimal spatter, making it ideal for both skilled welders and those still honing their craft. The J421 electrode finds application in various environments, ranging from construction sites to shipbuilding and automotive industries.

Exploring the China J421 Electrode Welding Supplier A Key Player in the Welding Industry

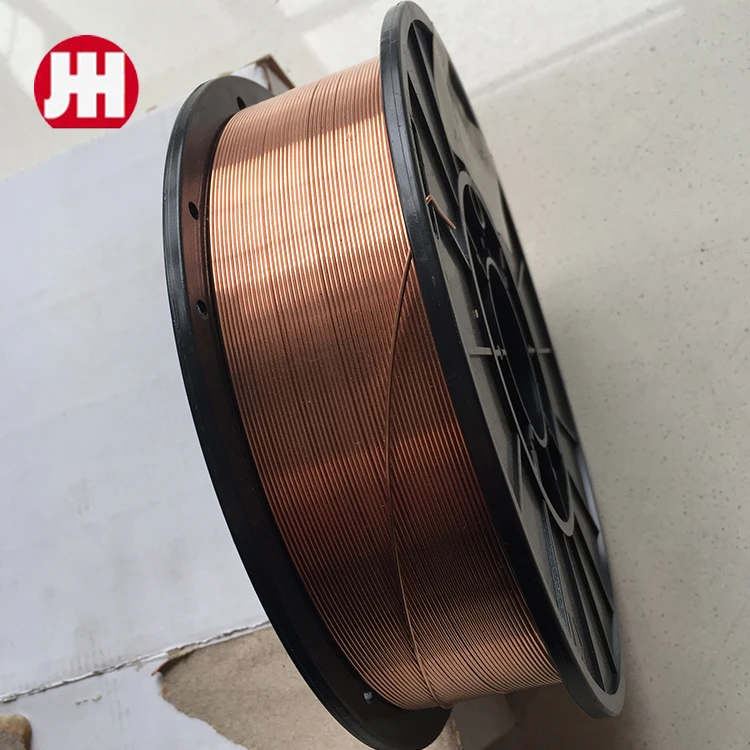

One significant advantage of sourcing J421 electrodes from China is the vast range of products available. Suppliers often offer various sizes and packaging options, catering to the unique needs of different industries. Additionally, many manufacturers in China are equipped with cutting-edge research and development facilities that allow them to innovate continuously. This focus on R&D is not only crucial for maintaining quality but also for developing new welding materials that enhance performance in specialized applications.

china j421 electrode welding supplier

Moreover, the logistical capabilities of Chinese suppliers play a vital role in their competitiveness. With established shipping routes and efficient supply chain management, these suppliers can deliver products quickly and reliably. This efficiency is essential for industries that operate under tight deadlines and require a constant supply of welding consumables.

However, potential buyers must exercise due diligence when selecting a supplier. It's important to consider factors such as the supplier's reputation, quality certifications, and customer service capabilities. Engaging in thorough research and seeking feedback from previous clients can help ensure that one partners with a reputable Chinese supplier of J421 electrodes.

Furthermore, as environmental concerns grow globally, many manufacturers are also focusing on producing eco-friendly welding electrodes. This approach aligns with international sustainability goals and caters to a market that increasingly values environmentally responsible practices. Suppliers that adopt such measures not only contribute to a greener future but also enhance their market appeal.

In conclusion, the China J421 electrode welding supplier landscape is a vital component of the global welding industry. With their combination of quality, innovation, and affordability, Chinese suppliers are well-positioned to meet the needs of businesses looking for reliable welding consumables. As the industry continues to evolve, it’s essential for buyers to stay informed and selective, ensuring they partner with suppliers that uphold high standards of quality and sustainability. Embracing these practices will lead to successful welding projects and a stronger, more sustainable future in manufacturing and construction.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025