Electrode 6011 Production and Suppliers in China for Welding Applications

Understanding China’s 6011 Electrodes Manufacturing

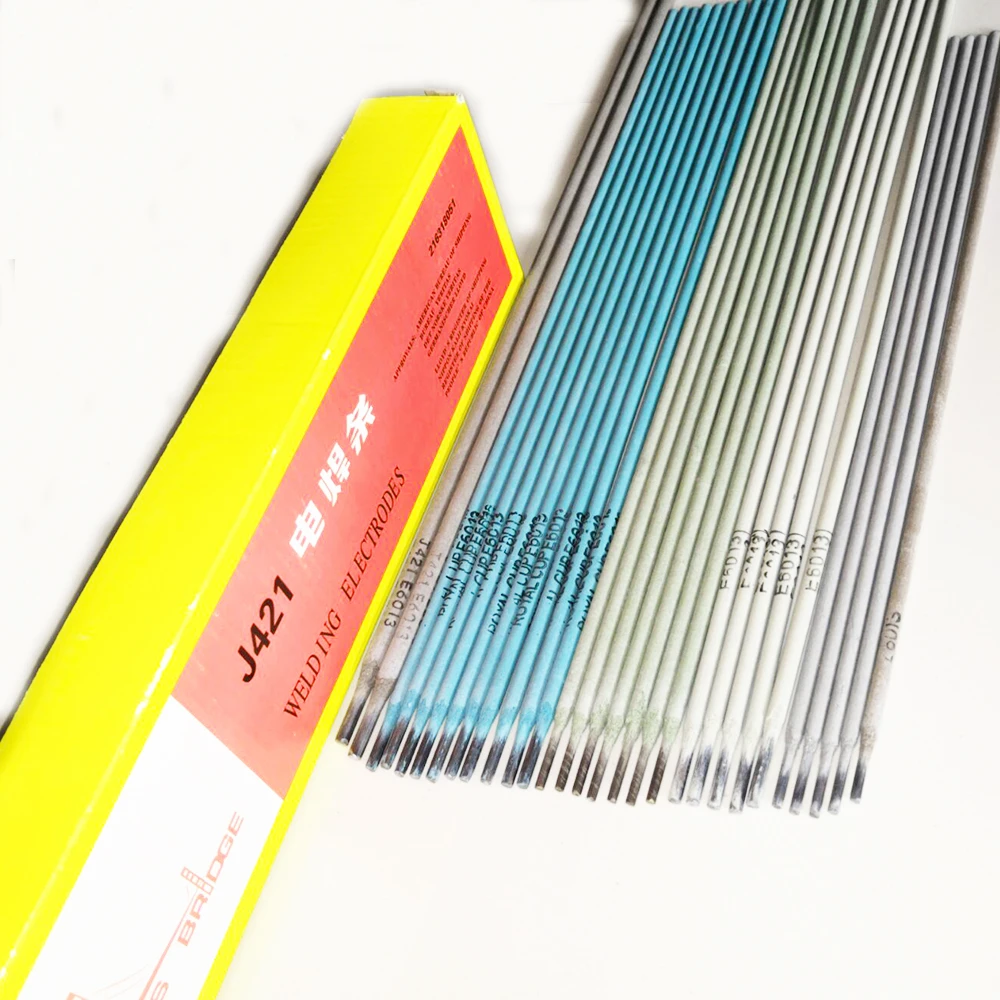

In the realm of welding, the importance of quality electrodes cannot be overstated. Among the various types of welding electrodes available in the market, the E6011 electrode holds a significant position, particularly in the construction and manufacturing sectors. Produced in vast quantities, especially in China, these electrodes are favored for their versatility and efficiency. This article explores the manufacturing process, applications, and advantages of 6011 electrodes, highlighting the key factories involved in their production in China.

What are E6011 Electrodes?

E6011 is a type of low-hydrogen electrode classified under the AWS (American Welding Society) numbering system. The “E” indicates an electrode, while “60” refers to the minimum tensile strength of 60,000 psi that the weld can achieve. The “1” designates that this electrode can be used in all positions, making it suitable for a variety of welding applications. These electrodes contain a high level of cellulose, which produces a shielding gas during the welding process, enhancing the quality of the weld.

The Manufacturing Process

The production of E6011 electrodes involves several critical steps to ensure their quality and performance. Factories in China utilize advanced technology and automation to maintain high standards in their output.

1. Raw Material Selection The process begins with the careful selection of raw materials, including steel wires and coating materials. The quality of these materials significantly influences the electrode's performance.

2. Wire Drawing The steel wires are drawn to the desired diameter, typically around 1/8 inch. This process requires precision to achieve the uniformity needed for consistent welding performance.

3. Coating The wires are then coated with a mixture of materials, including cellulose, potassium, and other compounds that enhance arc stability and the quality of the weld. This step is crucial, as the coating composition directly affects the electrode's characteristics.

4. Baking and Packaging After coating, the electrodes are baked to cure the coating properly. Once cured, they are cut to length, packaged, and undergo quality control tests to ensure they meet industry standards before being shipped out.

china soldadura electrodos 6011 factories

Several factories across China specialize in the production of E6011 electrodes. These facilities are equipped with advanced machinery and are staffed by skilled workers who ensure that every batch meets stringent quality criteria. Some notable manufacturers include companies based in Guangdong, Jiangsu, and Zhejiang provinces, known for their commitment to quality and innovation.

Applications of E6011 Electrodes

E6011 electrodes are widely used in various applications due to their versatility. They are particularly effective for welding thin materials and perform well on rusty or dirty surfaces. Common industries that utilize E6011 electrodes include

- Construction Used for structural steel welding, pipes, and general fabrication. - Automotive Ideal for repairing vehicles where quick and efficient welding is necessary. - Manufacturing Used in the production of machinery and equipment, ensuring robust connections.

Advantages of E6011 Electrodes

The E6011 electrodes are appreciated for several reasons

1. All-Position Welding Their ability to be used in all welding positions makes them versatile in various applications. 2. Excellent Penetration The design allows for deep welding penetration, ensuring strong weld joints. 3. Good Arc Stability This characteristic allows for easier control and more uniform welds.

4. Cost-Effectiveness Being widely produced in China, E6011 electrodes are often more affordable compared to other specialized electrodes, providing excellent value for users.

Conclusion

As the demand for quality welding solutions continues to grow, the importance of E6011 electrodes remains significant. With China as a leading manufacturer of these electrodes, the industry benefits from a blend of technology, skilled labor, and cost-effective production. Whether in construction, automotive, or manufacturing, the role of E6011 electrodes in achieving durable and reliable welds cannot be underestimated. As the industry evolves, ongoing innovations in electrode production will undoubtedly shape the future of welding in the global market.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025