China E6013 3.25mm Welding Electrode Supplier for Quality Welding Solutions

Understanding the E6013 Welding Electrode A Supplier's Perspective

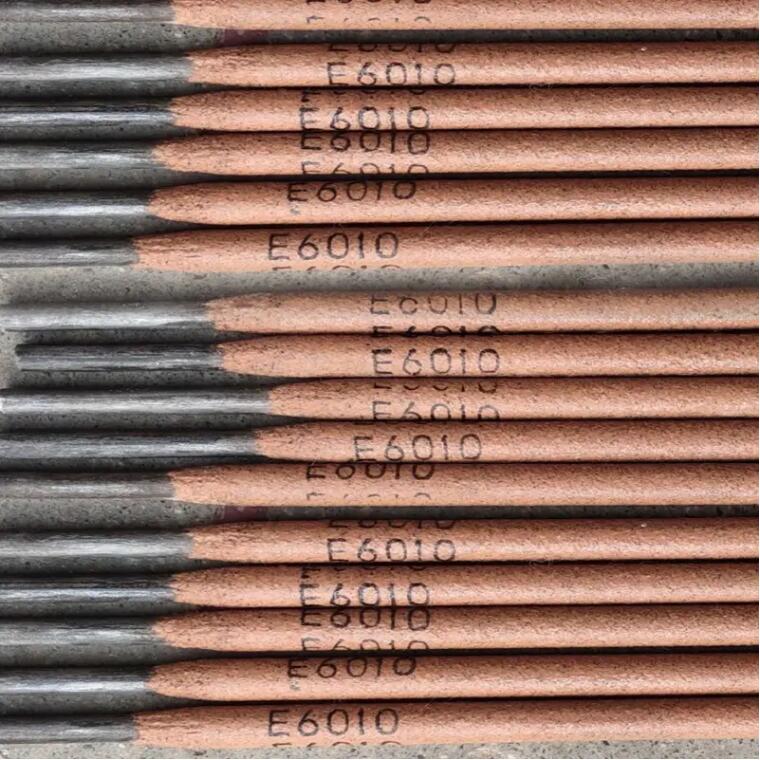

Welding is an essential process in many industries, enabling the joining of metals in a variety of applications, from construction to manufacturing. Among the many welding electrodes available, the E6013 electrode stands out as one of the most versatile options. This article explores the characteristics and benefits of the E6013 welding electrode, specifically the 3.25mm variant, and offers insights into sourcing this type of electrode from suppliers in China.

What is E6013?

The E6013 electrode is a type of coated mild steel electrode designed for shielded metal arc welding (SMAW). Its classification indicates specific properties and suitability for various welding tasks. The E signifies that it is an electrode, while the 60 indicates that it has a minimum tensile strength of 60,000 psi. The 1 denotes that it can be used in all positions, and 3 suggests that it is designed for welding with a smooth and manageable arc.

Characteristics of the E6013 Electrode

1. Versatility The E6013 electrode is suitable for a variety of welding positions, including flat, horizontal, vertical, and overhead work. This makes it an ideal choice for both beginners and experienced welders. 2. Good Arc Stability The electrode produces a stable arc with minimal spatter, ensuring cleaner welds and less post-weld cleaning. This is particularly important in precision welding applications where appearance and integrity are critical.

3. Ease of Use With its forgiving nature, the E6013 is an excellent choice for those still mastering their welding skills. It is less sensitive to interference from rust, dirt, and other contaminants on the workpiece.

4. Wide Application Range Typically used for welding low and medium strength steels, the E6013 electrode is employed in various environments, such as construction, automotive, shipbuilding, and more.

Why Choose 3

.25mm Diameter?The 3.25mm diameter E6013 electrode is particularly popular among welders. This size strikes a balance between usability and effectiveness. It allows for deeper penetration while still being manageable for overhead or delicate work. Smaller diameters are generally used for thin materials, while larger diameters are suitable for heavier applications. Therefore, the 3.25mm option serves as a versatile alternative for many common welding tasks, making it a staple in welding shops.

Importing from China

Given the growing demand for E6013 welding electrodes, sourcing them from suppliers in China has become increasingly popular. China is recognized for its robust manufacturing capabilities, and several reasons make it an attractive option for purchasing welding electrodes

china welding electrode e6013 3.25mm supplier

1. Competitive Pricing Chinese suppliers often provide competitive pricing due to lower production costs, making it economical for businesses to source high-quality welding materials.

2. Quality Control Many Chinese manufacturers are committed to maintaining high standards of quality. By adhering to ISO certifications and other relevant industry standards, they ensure that their products meet or exceed expectations.

3. Accessibility With a myriad of suppliers available online, it’s easier than ever to compare products, read reviews, and find credible manufacturers that meet specific needs.

4. Customization Suppliers are often open to customizing products to meet specific criteria, whether that means adjusting the coating composition or packaging to suit the needs of the buyer.

Selecting a Reliable Supplier

When selecting a supplier for E6013 electrodes, it is essential to consider several factors

- Reputation Research the supplier’s reputation through reviews and testimonials. Ensure they have a track record of delivering quality products on time.

- Product Specifications Confirm that the electrodes meet the required American Welding Society (AWS) specifications and other pertinent industry standards.

- After-Sales Support A good supplier should provide attentive customer service, including support for any potential issues post-purchase.

- Certifications Check for relevant certifications that confirm the quality and safety of the products, such as ISO or CE markings.

Conclusion

The E6013 welding electrode, particularly the 3.25mm variant, is an invaluable tool for an array of welding applications. With the increasing reliance on high-quality welding materials, sourcing these electrodes from reputable Chinese suppliers presents significant advantages in terms of cost and quality. By following a prudent selection process and being mindful of specific welding needs, businesses can ensure they have the right materials to achieve flawless welding results.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025