e7016 welding rod factories

E7016 Welding Rod Factories An Overview

Welding is an indispensable process in various industries, from construction to manufacturing, where strong and durable joints are needed. Among the many materials used for welding, E7016 welding rods stand out due to their unique properties and versatility. Manufacturing these rods requires specialized factories equipped with advanced technology, strict quality control measures, and a deep understanding of metallurgy.

What is E7016 Welding Rod?

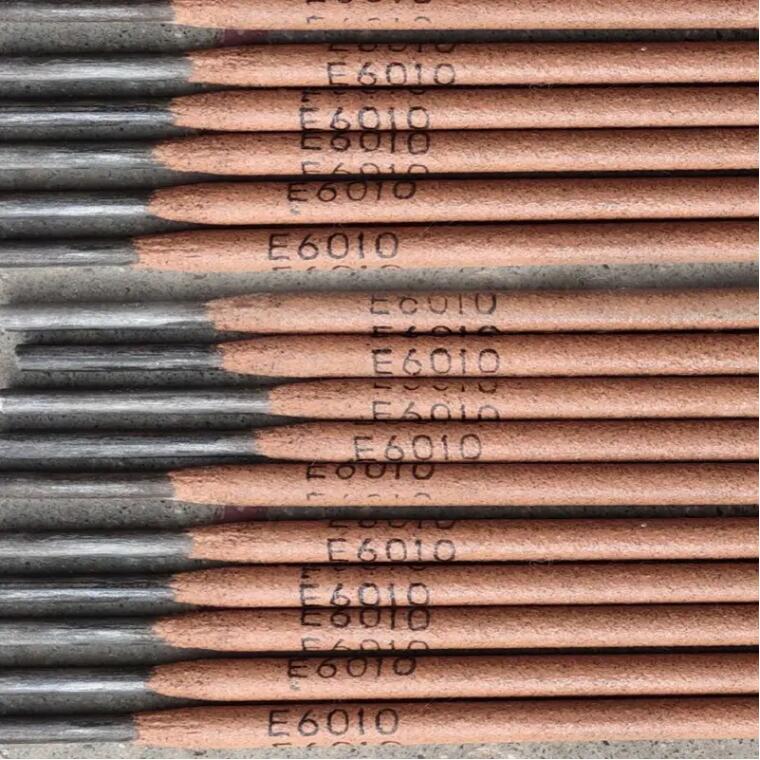

E7016 is a type of electrode classified under the American Welding Society (AWS) specifications. The E denotes that it is an electrode, while 70 signifies the minimum tensile strength of 70,000 psi. The 1 indicates that it can be used in all positions, and the 6 refers to the coating type, which is predominantly made of a high-silicon, low-hydrogen type suitable for welding steel. E7016 rods are commonly used for welding structural steel and fabricating components in various industrial applications due to their ability to produce strong, crack-resistant welds.

The Importance of Factories in Production

Welding rod factories play a crucial role in the production of E7016 electrodes. These facilities must adhere to rigorous industry standards and regulations to ensure the quality and safety of their products. The production process typically involves several key steps

1. Raw Material Sourcing Quality raw materials are critical for manufacturing E7016 rods. Factories need to source high-grade steel wire and appropriate coating materials to create rods that meet the specified tensile strength and ductility requirements.

2. Wire Drawing This process involves reducing the diameter of the steel wire from larger coils to the required thickness for welding rods. Precision is vital to ensure uniformity, which directly affects the performance of the welding electrode.

e7016 welding rod factories

3. Coating Application The coating is applied to the wire using sophisticated machinery. This step is crucial as it determines the characteristics of the weld. The coating should provide not only protection from contamination but also enhance the welding performance by stabilizing the arc and minimizing spatter.

4. Cutting and Packaging Once the rods are coated and dried, they are cut to the required lengths. Quality checks are performed at every stage, and the finished products are carefully packaged to prevent damage during transport.

5. Quality Control Factories must implement stringent quality control measures to ensure that every batch of E7016 rods meets the required specifications. This includes tensile strength tests, impact tests, and assessments of the electrode's consistency and performance.

Global Impact of E7016 Welding Rod Factories

In the global landscape, E7016 welding rod factories contribute significantly to the economic fabric of countries. Many industries, such as shipbuilding, automotive, and construction, rely on these rods for essential welding tasks. The demand for reliable and high-performing welding materials encourages factories to innovate and improve their production methods continually.

Moreover, the environmental aspect is becoming increasingly important. Many manufacturers are investing in sustainable practices, such as recycling scrap materials and reducing emissions throughout the production process. This aligns with the global push for greener manufacturing methods and enhances the industry's reputation.

Conclusion

E7016 welding rod factories represent a vital link in the welding supply chain. Their focus on quality, innovation, and sustainability ensures that industries have access to reliable materials for their operations. As technology progresses and the demand for high-quality welding rods increases, these factories will continue to play a pivotal role in the global economy and the advancement of welding technologies. With ongoing advancements, the future of E7016 welding rods looks promising, and their production will undoubtedly evolve to meet the changing needs of the industry.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025