Gasless Flux Cored Welding Wire Manufacturer for E71T-GS Quality Solutions

The E71T-GS Gasless Flux-Cored Welding Wire A Comprehensive Overview

Welding has long been an essential process in manufacturing and construction industries. It plays a pivotal role in joining metals, ensuring structural integrity and durability. Among the various types of welding methods and materials available, the E71T-GS gasless flux-cored welding wire has gained significant popularity, particularly for its convenience and versatility in various applications.

What is E71T-GS?

E71T-GS is a type of flux-cored wire that is designed for use in a gasless, or self-shielded, welding process. The “E” in E71T-GS signifies that it is an electrode; “71” indicates that it is suitable for welding steel with a minimum yield strength of 70,000 psi; “T” stands for tubular wire; and “GS” indicates that it is designed for gas shielded applications. However, unlike traditional flux-cored wires that require external shielding gas, the E71T-GS provides its own protection against atmospheric contamination through the flux contained within the wire.

Advantages of Using E71T-GS Welding Wire

1. Portability and Convenience One of the primary advantages of E71T-GS welding wire is its versatility. Because it does not require an external shielding gas, it is an ideal choice for outdoor welding or in windy conditions where gas shielding could be ineffective.

2. Ease of Use E71T-GS wires are relatively easy to use, making them suitable for both novice and experienced welders. The self-shielding properties reduce the need for extensive setup and preparation, allowing for quick adjustments and faster work execution.

3. Good Penetration and Fusion This welding wire is designed to provide excellent penetration and fusion on a variety of metals, particularly mild steel. The flux formula used in E71T-GS allows for better weld bead shape and is forgiving on metal preparation, enabling effective welding even on less-than-perfect surfaces.

4. Less Cleanup The slag produced during welding with E71T-GS is generally easier to remove than that from other types of flux-cored wires. This helps reduce post-welding cleanup time, contributing to overall productivity on the job.

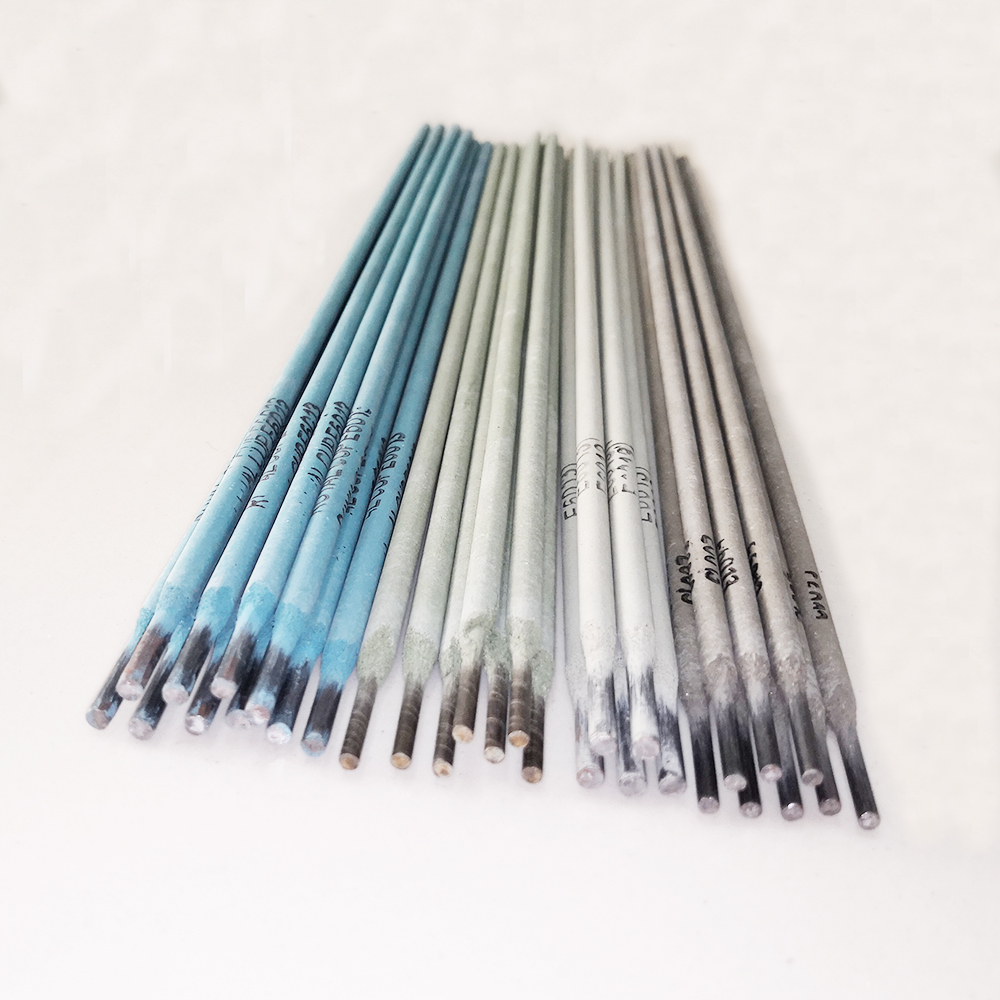

e71t-gs gasless flux cored welding wire manufacturer

5. Cost-Effectiveness E71T-GS welding wire typically comes at a lower cost compared to solid wires that require shielding gases. This cost-effectiveness makes it an attractive option for budget-conscious projects or for those engaging in frequent welding tasks.

Applications

E71T-GS wires are widely used in various applications, particularly in construction and repair work. They are commonly employed in

- Metal Fabrication The ease of use and adaptability to different joint configurations make E71T-GS a preferred choice for fabricating metal parts and structures. - Home Projects and DIY For hobbyists and DIY enthusiasts, this gasless flux-cored wire is an excellent option, allowing for flexible welding solutions without the hassle of gas tanks. - Maintenance and Repair The capacity for good penetration and adhesion makes it suitable for maintenance tasks where quick repairs are needed, particularly outdoors.

Considerations When Using E71T-GS

While E71T-GS welding wire presents numerous advantages, certain considerations should be kept in mind

- Welding Position Although E71T-GS wire performs well in various positions, vertical and overhead welding may require a practiced technique due to its flow characteristics. - Material Thickness It is most effective for welding material thicknesses between 18 gauge and 1/4 inch. For thicker materials, users may need to consider different wire or welding techniques.

Conclusion

In summary, E71T-GS gasless flux-cored welding wire serves as an invaluable tool for various welding applications. Its unique blend of portability, ease of use, and efficiency make it a top choice for welders working across multiple sectors. By understanding its benefits and characteristics, users can leverage the E71T-GS wire to enhance their welding capabilities and achieve high-quality results. Whether you're a professional welder or a novice looking to embark on a welding project, E71T-GS is undoubtedly worthy of consideration in your welding toolkit.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025