Selecting the Best Flux Core Stainless Steel Welding Wire for Your Projects

Understanding Flux Core Stainless Steel Wire A Comprehensive Guide

Flux core stainless steel wire is an essential material in the field of welding, prized for its unique properties and versatility in various applications. This article aims to explore what flux core stainless steel wire is, how it differs from other welding wires, its advantages, and some applications in industry and construction.

What is Flux Core Stainless Steel Wire?

Flux core stainless steel wire is a type of welding consumable used primarily for gas-shielded and self-shielded arc welding processes. Unlike solid welding wire, flux core wire contains a core of flux material. This flux, when heated, generates a gas that protects the weld from contamination by the atmosphere. The advantage of this design is that it can be used in environments where shielding gas may not be practical, such as outdoor conditions with wind.

Stainless steel flux core wires are particularly formulated for work involving stainless steel components. They possess properties that make them ideal for joining and repairing stainless steel structures, including enhanced corrosion resistance and strength, which are critical in many applications.

Differences from Solid Welding Wire

One of the primary differences between flux core stainless steel wire and solid welding wire lies in their composition and function. Solid wire requires an external shielding gas to protect the weld pool from oxidation, while flux core wire provides its own shielding through the self-generated gas from the flux. This capability makes flux core wire advantageous when working outdoors or in variable weather conditions.

Moreover, flux core wires generally allow for higher deposition rates and can be used in a broader range of positions (flat, horizontal, vertical, and overhead), making them ideal for completing tasks more efficiently.

Advantages of Flux Core Stainless Steel Wire

1. Versatility Flux core stainless steel wire can be used on various stainless steel grades, including austenitic and ferritic stainless steels, making it an excellent choice for many welding projects.

2. Efficiency Due to the continuous feeding of wire and the reduced need for external gases, the welding process is generally faster compared to using solid wire.

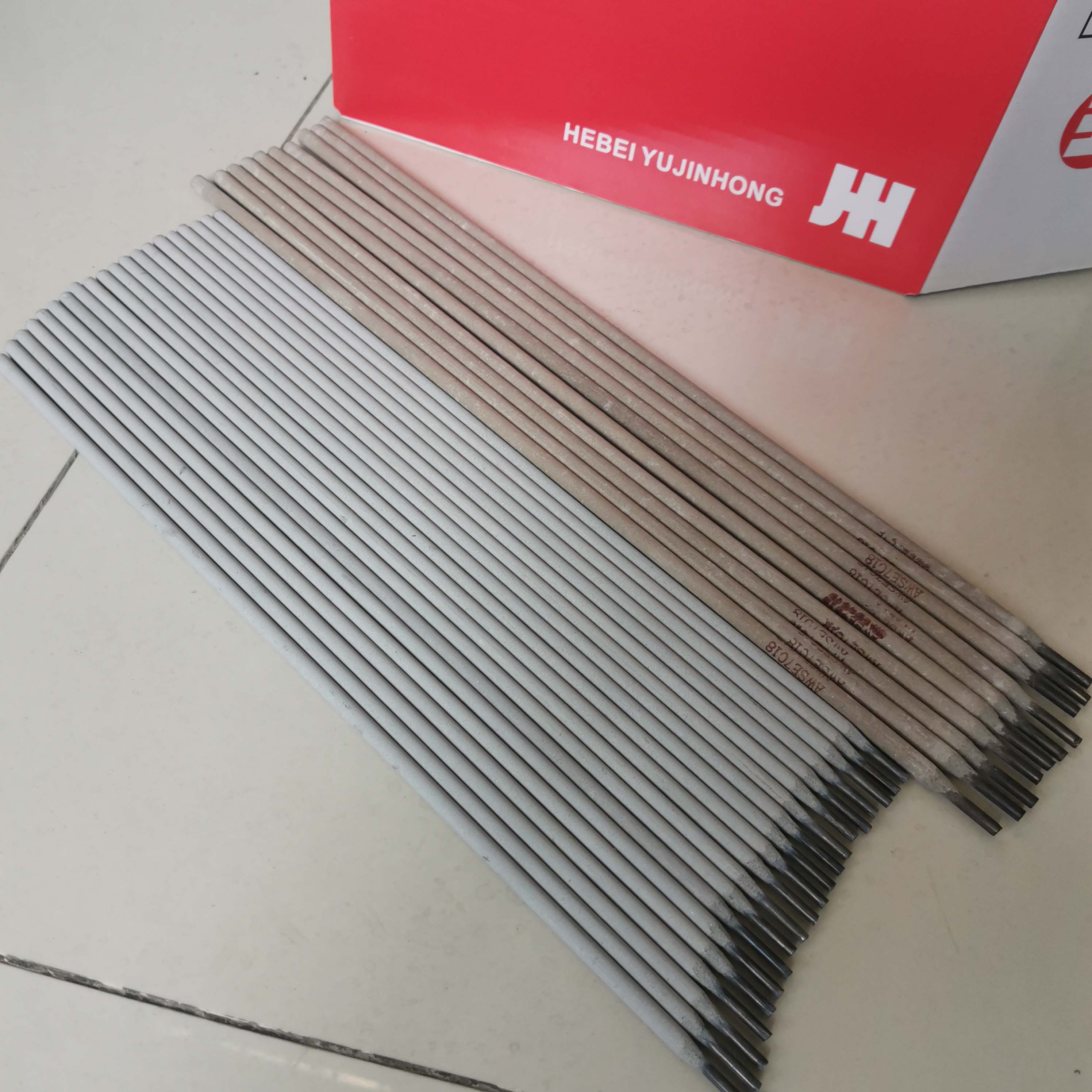

flux core stainless wire

3. Strong Welds The flux core design contributes to strong, durable welds that often have superior mechanical properties and resistance to pitting and corrosion.

5. All-Position Capability Flux core welding can be performed in all positions, accommodating various applications and work environments.

Applications of Flux Core Stainless Steel Wire

The application of flux core stainless steel wire is incredibly diverse. It is predominantly used in industries such as construction, shipbuilding, and pipeline welding. Hospitals and food processing facilities also utilize it for its hygienic properties, as stainless steel is easier to clean and sanitize.

1. Food Processing Industry The use of flux core stainless steel wire is common in building processing equipment, where structural integrity and cleanliness are paramount to avoid contamination.

2. Marine Applications In shipbuilding, the ability of stainless steel to withstand harsh marine environments makes it an ideal material. Flux core welding techniques are employed to construct boats and ships that can endure corrosion and other challenges posed by saltwater.

3. Structural Applications In architecture and construction, flux core stainless steel is used to create structural components that require strength, durability, and resistance to the elements.

4. Industrial Equipment Repair Flux core stainless steel wire is also used for repairing industrial equipment made from stainless steel, ensuring that structures can be maintained and reused efficiently.

Conclusion

Flux core stainless steel wire is a pivotal component in the welding industry due to its unique properties and advantages. Its ability to deliver strong, durable welds with minimal environmental impact makes it an essential choice for professionals in various fields. As the demand for stainless steel applications continues to grow, understanding and utilizing flux core welding techniques will remain crucial in maintaining efficiency and structural integrity in welding projects. Whether in construction, food processing, or marine industries, this versatile welding material is a game-changer.

-

3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High QualityNewsJul.04,2025

-

Stainless Steel Welding Rods for Sale – High Quality 7018 Welding Rods SupplierNewsJul.04,2025

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025