Jan . 10, 2025 09:06

Back to list

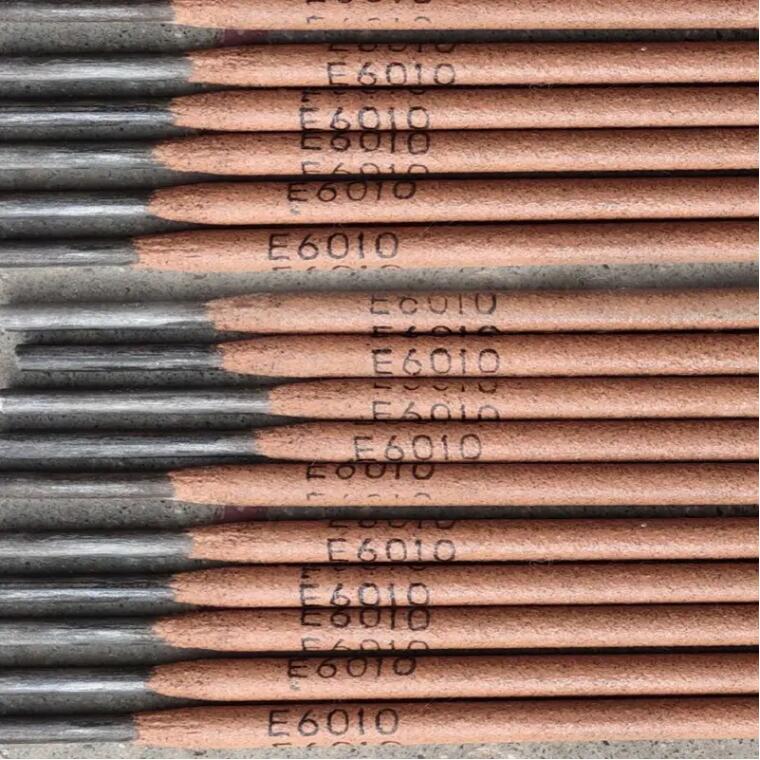

welding rods 6010

Welding rods 6010 are an essential staple in the world of arc welding, renowned for their effectiveness across various applications. Their unique composition and functionality cater to a range of industries, making them a versatile choice for professionals and hobbyists alike. Delving deeper into the characteristics and best practices associated with 6010 rods can guide users to achieve optimal results while maintaining safety and efficiency.

In terms of authoritativeness, 6010 rods have gained a reputation through decades of consistent performance. They are frequently recommended by welding associations and standards bodies such as the American Welding Society (AWS) for projects that involve pipelines and structural welding. Their reliability under pressure and in demanding environments has solidified their standing in written standards and recommendations, affirming their pivotal role within the welding community. A key aspect of trustworthiness with 6010 rods is the stringent quality controls employed during manufacturing. Reputable manufacturers guarantee that the rods meet specific AWS requirements, ensuring that welders receive tools that perform consistently across various conditions. Trust in these rods also stems from their proven track record in critical applications such as pipeline construction, where failure is not an option. To conclude, welding rods 6010 offer a blend of robust capabilities and dependable performance that cater to both demanding professional standards and versatile hobby applications. Real-world experiences underline their efficiency in root passing and working with poor-fit or rusted materials. Expert handling of these rods can lead to stunning results, backed by authoritative endorsements and a solid foundation of trust built over years of use. For anyone looking to enhance their welding prowess or tackle challenging projects, the 6010 rod remains an indispensable tool in their arsenal.

In terms of authoritativeness, 6010 rods have gained a reputation through decades of consistent performance. They are frequently recommended by welding associations and standards bodies such as the American Welding Society (AWS) for projects that involve pipelines and structural welding. Their reliability under pressure and in demanding environments has solidified their standing in written standards and recommendations, affirming their pivotal role within the welding community. A key aspect of trustworthiness with 6010 rods is the stringent quality controls employed during manufacturing. Reputable manufacturers guarantee that the rods meet specific AWS requirements, ensuring that welders receive tools that perform consistently across various conditions. Trust in these rods also stems from their proven track record in critical applications such as pipeline construction, where failure is not an option. To conclude, welding rods 6010 offer a blend of robust capabilities and dependable performance that cater to both demanding professional standards and versatile hobby applications. Real-world experiences underline their efficiency in root passing and working with poor-fit or rusted materials. Expert handling of these rods can lead to stunning results, backed by authoritative endorsements and a solid foundation of trust built over years of use. For anyone looking to enhance their welding prowess or tackle challenging projects, the 6010 rod remains an indispensable tool in their arsenal.

Next:

Latest news

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025