Fév . 14, 2025 19:15

Back to list

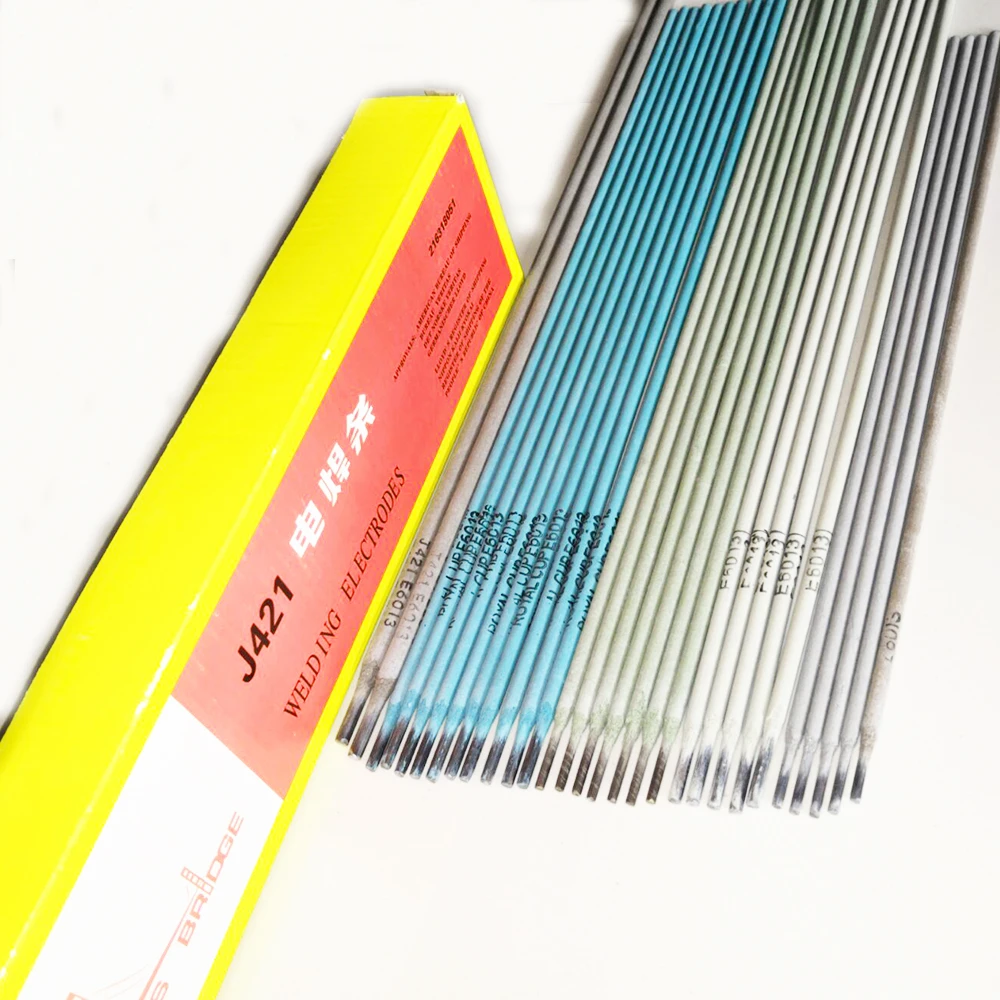

3.2mm 4mm 7018 welding rods electrodes

Wholesale 3.2mm welding electrodes have become a fundamental component in metalwork, carving their significance in various industries where welding is an integral process. These electrodes, otherwise known as welding rods, serve as a critical element in the establishment of strong, reliable joints and seams in metal structures. Their quality can significantly influence the outcome of any welding project, be it for construction, repair, or manufacturing.

Beyond quality, trust in wholesale dealings is crucial. The best suppliers extend their expertise to assist clients in addressing specific challenges or innovating to enhance productivity. Their role transcends selling to becoming partners in their customers’ success, offering guidance on optimal usage, storage conditions to preserve electrode integrity, and troubleshooting common welding issues. Such interactions build long-term relationships grounded in reliability and result-oriented communication. Welding professionals, therefore, prioritize procuring electrodes from wholesales that commit to an extensive vetting process and offer transparent information regarding performance and compatibility. Technical specifications are not shrouded in ambiguity but laid out to empower buyers to make informed decisions, reinforcing trust at the transactional level. Moreover, innovation in electrode manufacturing, such as eco-friendly coatings and optimized alloy mixes, resonates with contemporary industry movements towards sustainability and efficiency. Wholesalers who innovate in these directions set benchmarks within the domain, carving a unique space that aligns with global best practices and environmental considerations. In essence, wholesale 3.2mm welding electrodes stand as a testament to technical mastery and industrial advancement. For every stakeholder from the workshop floor to corporate procurement, understanding and sourcing these components are vital to affirming structural integrity, enhancing operational efficiency, and ensuring the longevity of metallic assemblies. The pursuit of excellence through strategic wholesaling and knowledgeable application fortifies not just structures but also the reputations of all involved.

Beyond quality, trust in wholesale dealings is crucial. The best suppliers extend their expertise to assist clients in addressing specific challenges or innovating to enhance productivity. Their role transcends selling to becoming partners in their customers’ success, offering guidance on optimal usage, storage conditions to preserve electrode integrity, and troubleshooting common welding issues. Such interactions build long-term relationships grounded in reliability and result-oriented communication. Welding professionals, therefore, prioritize procuring electrodes from wholesales that commit to an extensive vetting process and offer transparent information regarding performance and compatibility. Technical specifications are not shrouded in ambiguity but laid out to empower buyers to make informed decisions, reinforcing trust at the transactional level. Moreover, innovation in electrode manufacturing, such as eco-friendly coatings and optimized alloy mixes, resonates with contemporary industry movements towards sustainability and efficiency. Wholesalers who innovate in these directions set benchmarks within the domain, carving a unique space that aligns with global best practices and environmental considerations. In essence, wholesale 3.2mm welding electrodes stand as a testament to technical mastery and industrial advancement. For every stakeholder from the workshop floor to corporate procurement, understanding and sourcing these components are vital to affirming structural integrity, enhancing operational efficiency, and ensuring the longevity of metallic assemblies. The pursuit of excellence through strategic wholesaling and knowledgeable application fortifies not just structures but also the reputations of all involved.

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025